Oil-containing sludge treatment method and process flow

A sludge treatment and sludge technology, which is used in dewatering/drying/concentrating sludge treatment, petroleum industry, pyrolysis treatment of sludge, etc. Failure to meet environmental protection requirements and other issues, to achieve the effect of low freezing point, good oil quality, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

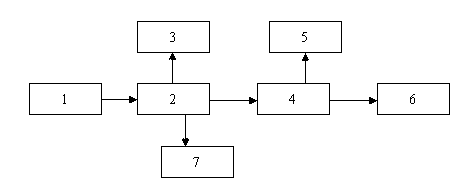

Image

Examples

Embodiment 1

[0027] Example 1: Treatment of oilfield crude oil storage tank bottom sludge

[0028] 1. Add sodium hydroxide to the oily sludge with a water content greater than 70% to adjust the pH value to 7.5, then add 200 mg / L of polyaluminum chloride and 5 mg / L of cationic polyacrylamide, and then enter the dehydration device 1 for dehydration treatment. The moisture content of the sludge after dehydration is 68.4%;

[0029] 2. The dehydrated oily sludge enters the pyrolysis device 2 for pyrolysis at 400°C, and the reaction time is 1.5 hours; only 40%-50% of the crude oil contained in the oily sludge is recovered (that is, the recovered crude oil accounts for 40-50% of the total crude oil content in the sludge);

[0030] 3. The cracked gas produced by pyrolysis enters the gas recovery device 3 for recycling;

[0031] 4. The oil and water produced by pyrolysis enter the oil-water separation device 4 for oil-water separation, the separated oil enters the oil storage tank 5 for recycling...

Embodiment 2

[0037] Example 2: Treatment of Oily Sludge in Crude Oil Storage Tanks of Refinery

[0038] 1. Add sodium hydroxide to the oily sludge with a water content greater than 70% to adjust the pH value to 7.5, then add 200 mg / L of polyaluminum chloride and 5 mg / L of cationic polyacrylamide, and then enter the dehydration device 1 for dehydration treatment. The moisture content of the sludge after dehydration is 66.7%;

[0039] 2. The oily sludge after dehydration enters the pyrolysis device 2, and is pyrolyzed at a low temperature at 380°C. The reaction time is 1.5 hours; only 40%-50% of the crude oil contained in the oily sludge is recovered (ie: recovered crude oil Accounting for 40-50% of the total crude oil content of oily sludge);

[0040] 3. The cracked gas produced by pyrolysis enters the gas recovery device 3 for recycling;

[0041] 4. The oil and water produced by pyrolysis enter the oil-water separation device 4 for oil-water separation, the separated oil enters the oil s...

Embodiment 3

[0047] Example 3: Treatment of Oily Sludge in Refinery Sludge Pool

[0048] 1. Add hydrochloric acid to the oily sludge with a water content greater than 70% to adjust the pH value to 7.0, then add 200 mg / L of polymeric iron and 5 mg / L of cationic polyacrylamide, and then enter the dehydration device 1 for dehydration treatment. After the oily sludge is dehydrated Moisture content is 65.8%;

[0049] 2. The dehydrated oily sludge is pyrolyzed at 300°C, and the reaction time is 1 hour;

[0050] 3. The residual pyrolysis sludge is made by adding 30% coke, 0.01% potassium chlorate, 0.5% lime clinker and 0.5% calcium oxide (magnesia or zinc oxide) into the fuel preparation device. For the use of fuel particles, the above percentages are all mass percentages.

[0051] After the above steps, the test results of the oily sludge in the crude oil storage tank of the refinery are shown in Table 3:

[0052] Table 3 Test results after treatment of oily sludge in refinery sludge pool

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com