Non-sulfide mineral flotation collector, preparation method thereof and application thereof

A technology of mineral flotation and non-sulfide minerals, applied in flotation, solid separation, etc., can solve the problems of low selectivity, poor frost resistance, poor dispersion, etc., and achieve good selectivity, low cost, less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

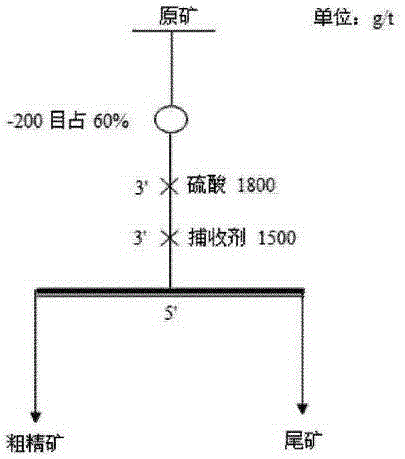

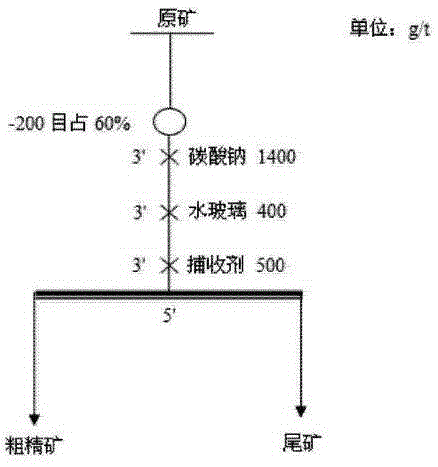

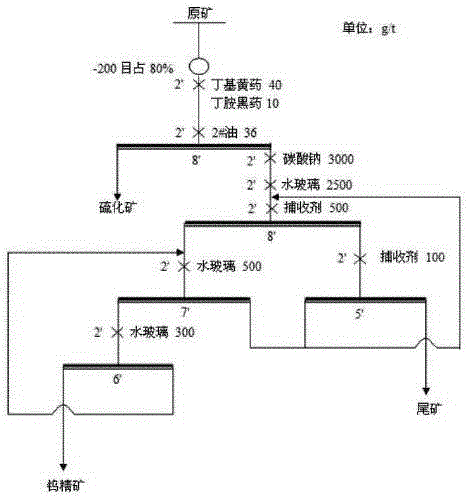

Method used

Image

Examples

Embodiment 1

[0040] The non-sulfide ore mineral flotation collector of the present embodiment is made from the raw materials of the following mass percentage ratio: 90% sodium oleate, 5% phosphate-2-ethylhexyl ester, and the balance is water; The pH value of sulfide ore mineral flotation collector is about 10.

[0041] The preparation method of the non-sulfide mineral flotation collector in this example is: mix 900kg sodium oleate, 50kg-2-ethylhexyl phosphate and 50kg water, heat to 60°C and stir for 1.5h.

Embodiment 2

[0043] The non-sulfide ore mineral flotation collector of the present embodiment is made from the raw materials of the following mass percentage ratio: 70% of oxidized paraffin wax soap, 12% of phosphate-2-ethylhexyl ester, and the balance is water; The pH value of sulfide ore mineral flotation collector is about 10.

[0044] The preparation method of the non-sulfide ore mineral flotation collector in this example is: mix 700kg sodium oleate, 120kg 2-ethylhexyl phosphate and 180kg water, heat to 80°C and stir for 1.5h.

Embodiment 3

[0046] The non-sulfide ore mineral flotation collector of the present embodiment is made of the following raw materials in proportion by mass: 60% sodium oleate, 30% phosphate-2-ethylhexyl ester, and the balance is water; The pH value of sulfide ore mineral flotation collector is about 9.

[0047] The preparation method of the non-sulfide mineral flotation collector in this example is: mix 600kg sodium oleate, 300kg 2-ethylhexyl phosphate and 100kg water, heat to 80°C and stir for 1.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com