Environment friendly antifreezing stone-like paint and preparation thereof

A real stone paint, environmental protection technology, applied in the direction of coating, can solve the problems of blooming, increased VOC, high cost, and achieve the effect of reducing VOC content, strong green environmental protection, and fast film forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

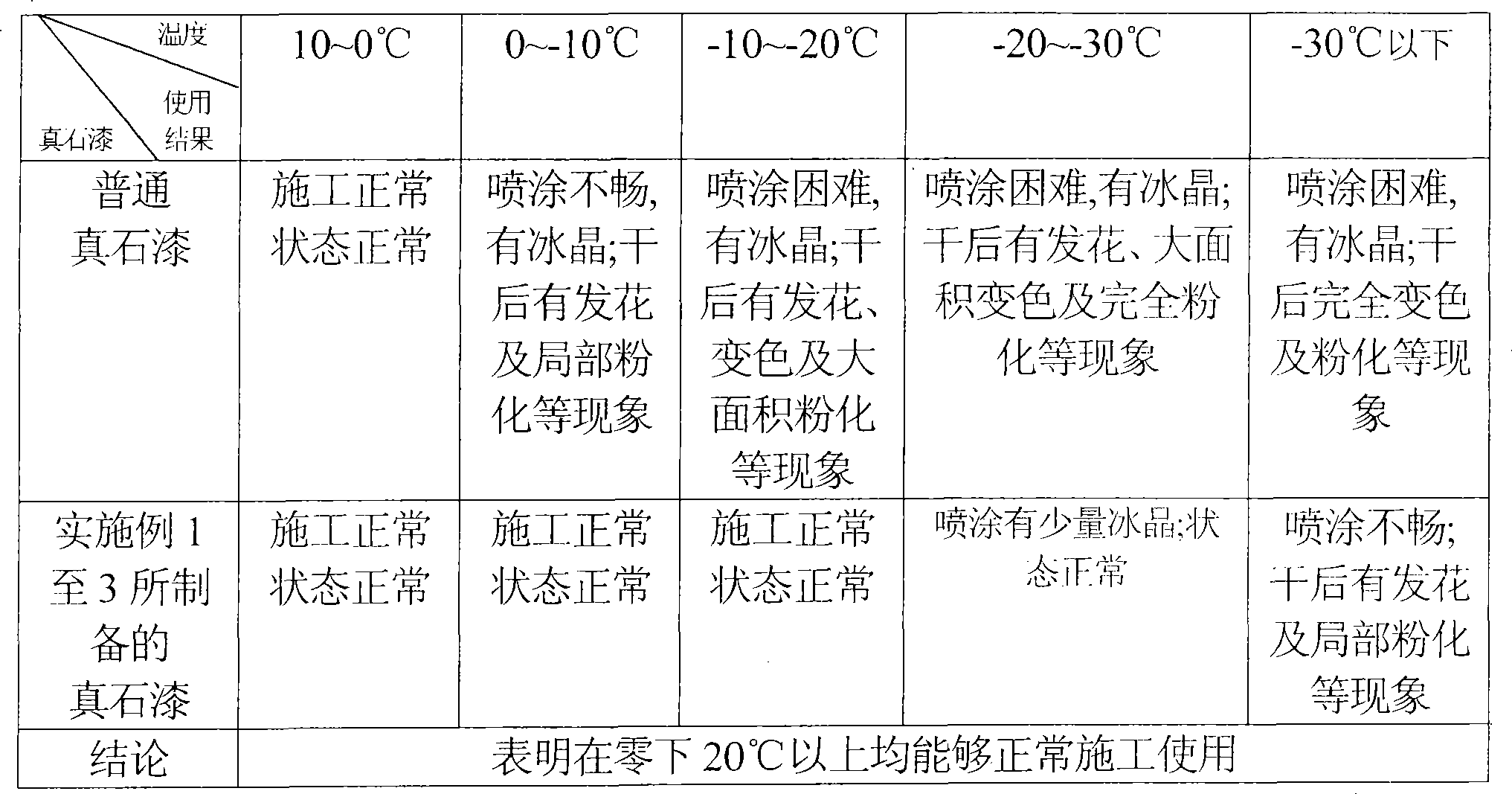

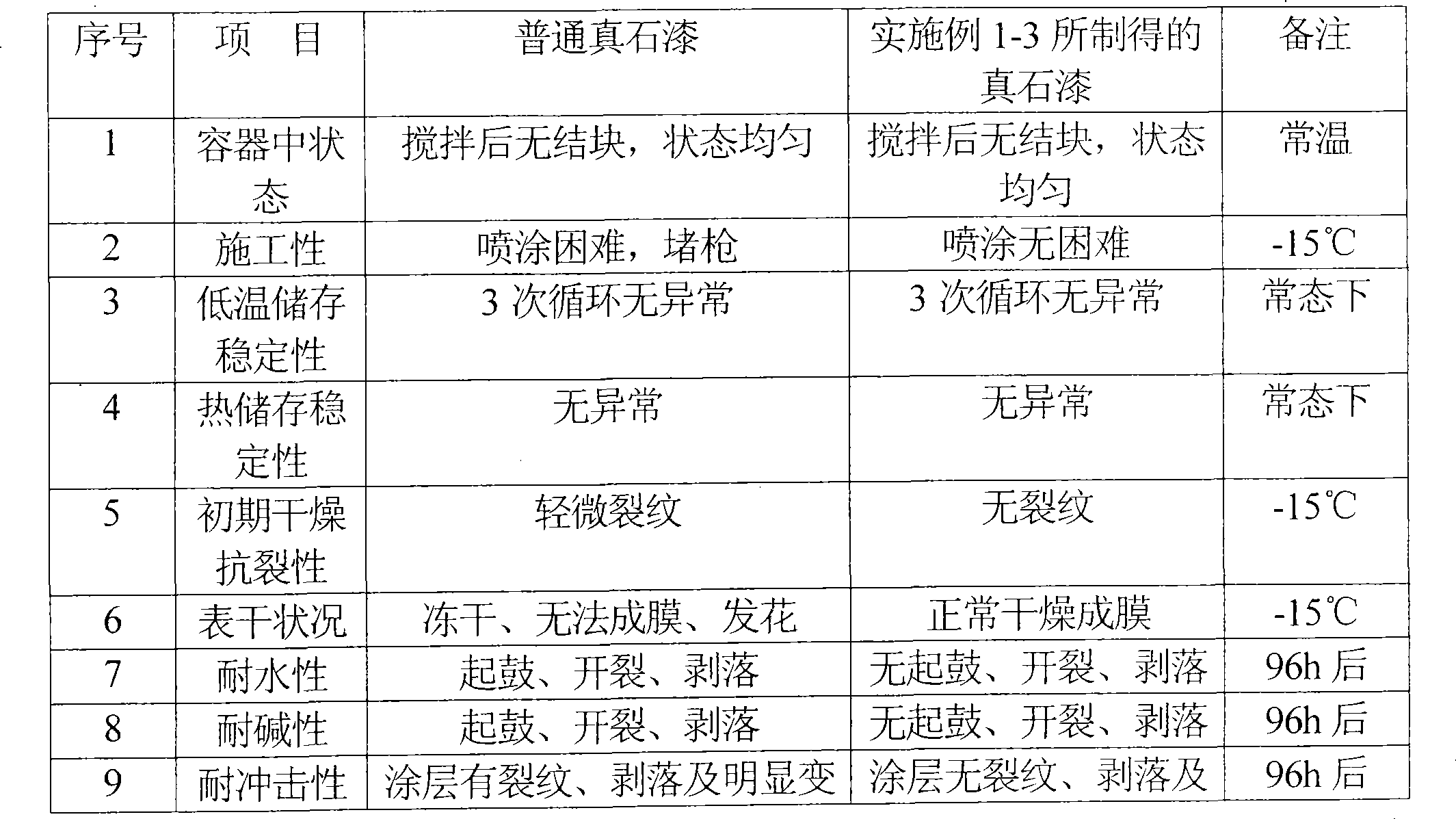

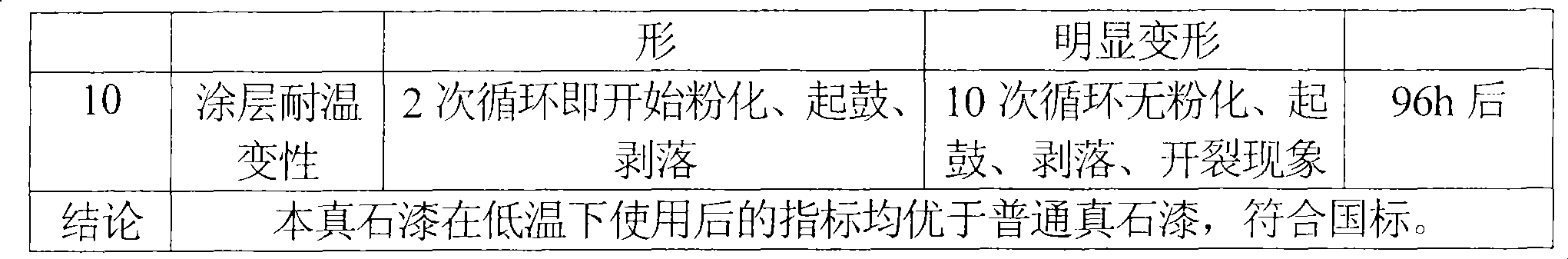

Examples

Embodiment 1

[0023] Prepare the environmental protection antifreeze genuine stone paint of the present invention according to the following steps:

[0024] 1) First add 9.9kg of water into the small container, and add 100g of HEC hydroxyethyl cellulose to the water under stirring conditions, stirring for 0.5h, stop stirring after the HEC particles are completely dissolved, and set aside;

[0025] 2) Weigh the following raw material components: 0.1kg of 1% concentration HEC hydroxyethyl cellulose aqueous solution, 0.8kg of ethylene glycol, 0.02kg of HY608 preservative, 4kg of 20 mesh colored sand, 50kg of 41 mesh colored sand, 81 mesh Color sand 5kg, KE025 acrylic emulsion 17kg, alcohol ester-12 additive 0.6kg, SP202 defoamer 0.02kg, ASE60 thickener 0.01kg and HY96 neutralizer 0.02kg;

[0026] 3) Add the following components into the mixer: ethylene glycol, half weight of alcohol ester-12 additives, SP202 defoamer, KE025 acrylic emulsion, HEC hydroxyethyl cellulose aqueous solution, stir fo...

Embodiment 2

[0030] Prepare the environmental protection antifreeze genuine stone paint of the present invention according to the following steps:

[0031] 1) First add 9.6kg of water to the small container, and add 400g of HEC hydroxyethyl cellulose to the water under stirring conditions, stirring for 2 hours, stop stirring after the HEC particles are completely dissolved, and set aside;

[0032] 2) Weigh the following raw material components: 5 kg of 4% concentration HEC hydroxyethyl cellulose aqueous solution, 1.2 kg of ethylene glycol, 0.1 kg of HY608 preservative, 70 kg of 80-mesh colored sand, 25 kg of 120-mesh colored sand, KE025 acrylic emulsion 23kg, alcohol ester-12 additive 0.9kg, SP202 defoamer 0.06kg, ASE60 thickener 0.1kg and HY96 neutralizer 0.06kg;

[0033] 3) Add the following components into the mixer: ethylene glycol, half weight of alcohol ester-12 additives and SP202 defoamer, KE025 acrylic emulsion, HEC hydroxyethyl cellulose aqueous solution, stir for 10 minutes, the...

Embodiment 3

[0037] Prepare the environmental protection antifreeze genuine stone paint of the present invention according to the following steps:

[0038] 1) Add 9.8kg of water in a small container, and add 200g of HEC hydroxyethyl fiber to the water under stirring conditions

[0039] element, the stirring time is 1h, after the HEC particles are completely dissolved, the stirring can be stopped and set aside;

[0040]2) Weigh the following raw material components: 3kg of 2% concentration HEC hydroxyethyl cellulose aqueous solution, 1kg of ethylene glycol, 0.05kg of HY608 preservative, 3kg of 30 mesh colored sand, 65kg of 60 mesh colored sand, 100 mesh colored sand 15kg, KE025 acrylic emulsion 20kg, alcohol ester-12 additive 0.75kg, SP202 defoamer 0.04kg, ASE60 thickener 0.05kg and HY96 neutralizer 0.04kg;

[0041] 3) Add the following components into the mixer: ethylene glycol, half weight of alcohol ester-12 additives and SP202 defoamer, KE025 acrylic emulsion, HEC hydroxyethyl cellulos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com