Supercritical carbon dioxide completion fluid

A carbon dioxide, supercritical technology, used in wellbore/well components, bulk chemical production, chemical instruments and methods, etc., can solve problems affecting the solidification process of cement slurry, reduce cement slurry density, reduce cement strength, etc. problems, to achieve good cementing effect, reduce freezing point, and improve longitudinal shear strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

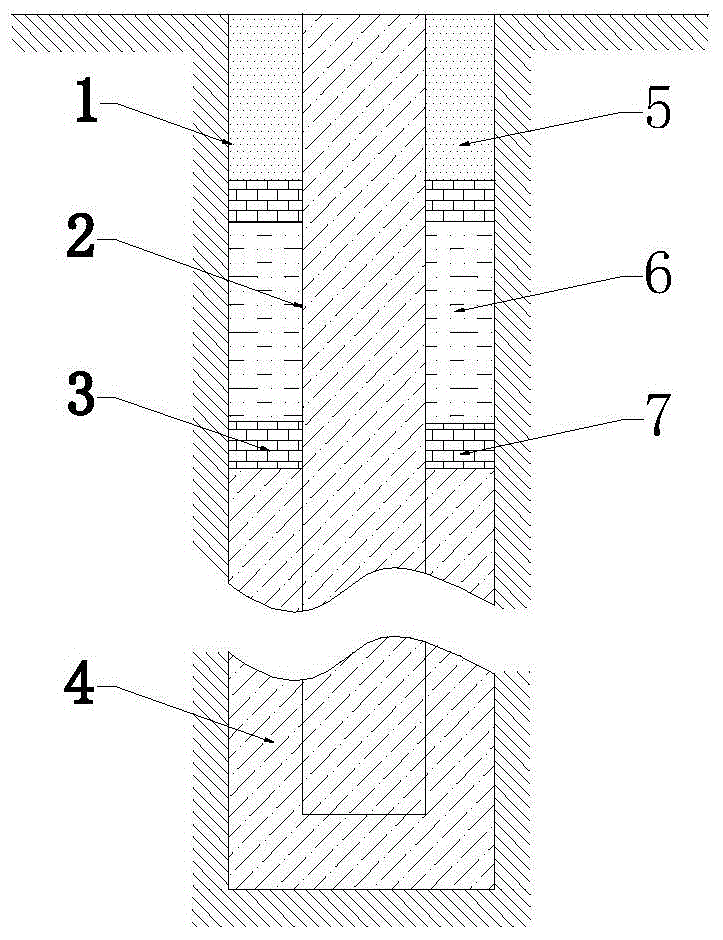

[0012] In this embodiment, the composition form of the supercritical carbon dioxide flushing fluid 6 is selected according to the formation characteristics of the well wall 1 and the characteristics of the drilling fluid 5, and the liquid carbon dioxide flushing fluid 6 is prepared on the ground, and the cementing slurry 4 is prepared. According to the drilling fluid 5 and Compatibility of cementing cement slurry 4 and supercritical carbon dioxide flushing fluid 6, pre-preparation spacer fluid 3 and post-placement spacer fluid 7 are prepared; Spacer fluid 3, supercritical carbon dioxide flushing fluid 6, rear spacer fluid 7 and cement slurry 4, as the depth increases and the temperature rises, the carbon dioxide in them becomes supercritical; the supercritical carbon dioxide enters the borehole wall 1 and the casing The annulus between the two spaces washes and cleans the mud cake on the well wall 1 and casing 2; after the flushing, wait for the cement slurry 4 to solidify; aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com