Method for processing string beans through vacuum freeze drying

A technology of vacuum freeze-drying and processing method, which is applied in the direction of freezing/refrigerating preservation of fruits/vegetables, food preservation, and fresh-keeping of fruits and vegetables, etc. problem, to solve the effect of poor rehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

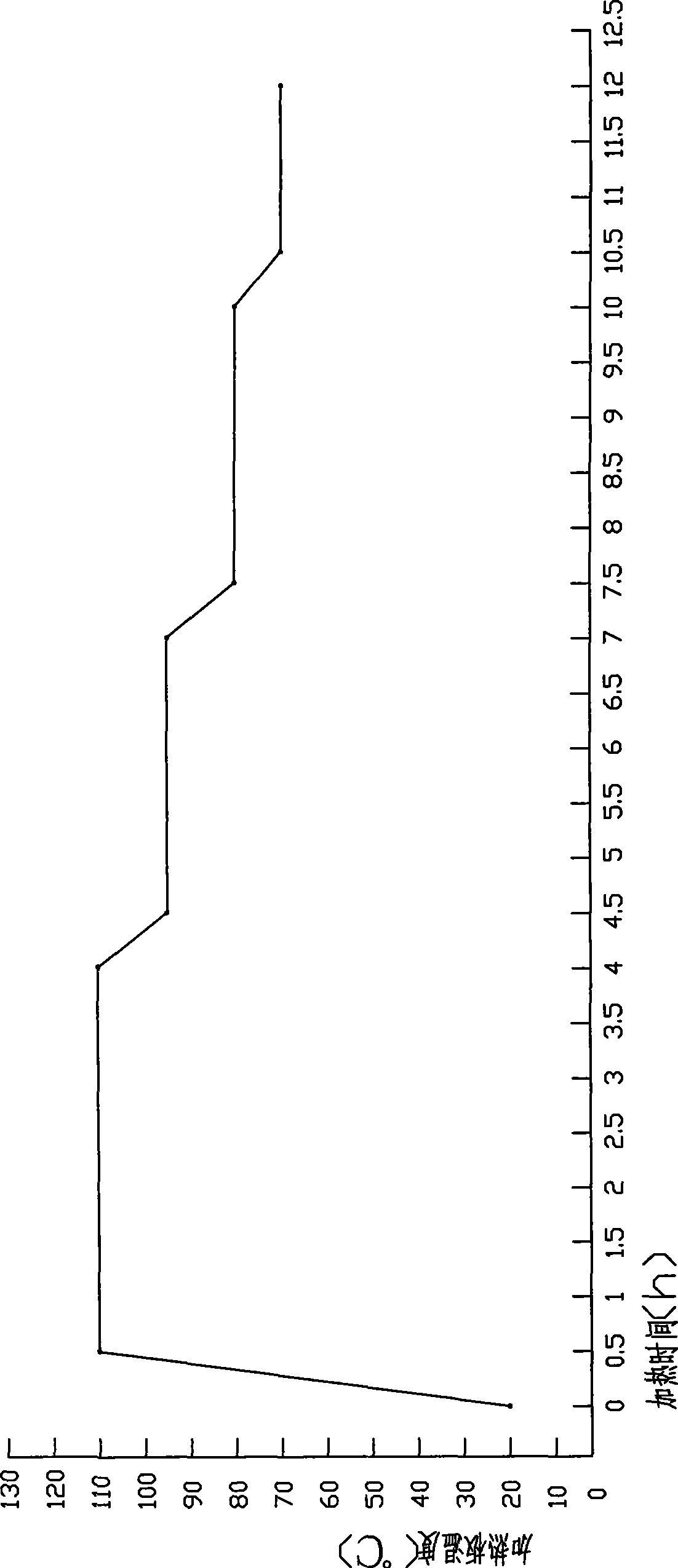

[0019] Depend on figure 1 Shown, a kind of processing method of vacuum freeze-dried green beans, processing method is as follows:

[0020] 1. Material selection: fresh green beans or frozen green beans are used as raw materials, and the varieties and sizes of beans are required to be uniform and uniform in color;

[0021] 2. Pretreatment: puncture fresh green beans directly with a piercer, while frozen green beans need to be punctured first and then thawed;

[0022] 3. Soaking and color protection: Soak the punctured green beans in 0.05% sodium carbonate solution and 0.08% zinc gluconate solution for 60 minutes, then rinse twice with water;

[0023] 4. Blanching: Put the soaked green beans into 0.046% sodium bicarbonate solution for blanching, the blanching temperature is 95-98°C, and the blanching time is generally 5-8 minutes;

[0024] 5. Cooling and draining: After blanching, remove the green beans from the blanching liquid, quickly put them in cooling water to cool to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com