Electric machine stator wire bar multifactor ageing device and method

A motor stator and aging device technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems that the aging process of motor wire rod insulation cannot be simulated, and the aging law and conclusion of stator insulation cannot be obtained, so as to reduce contact The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and the specific examples completed by the inventor according to the above-mentioned technical solutions.

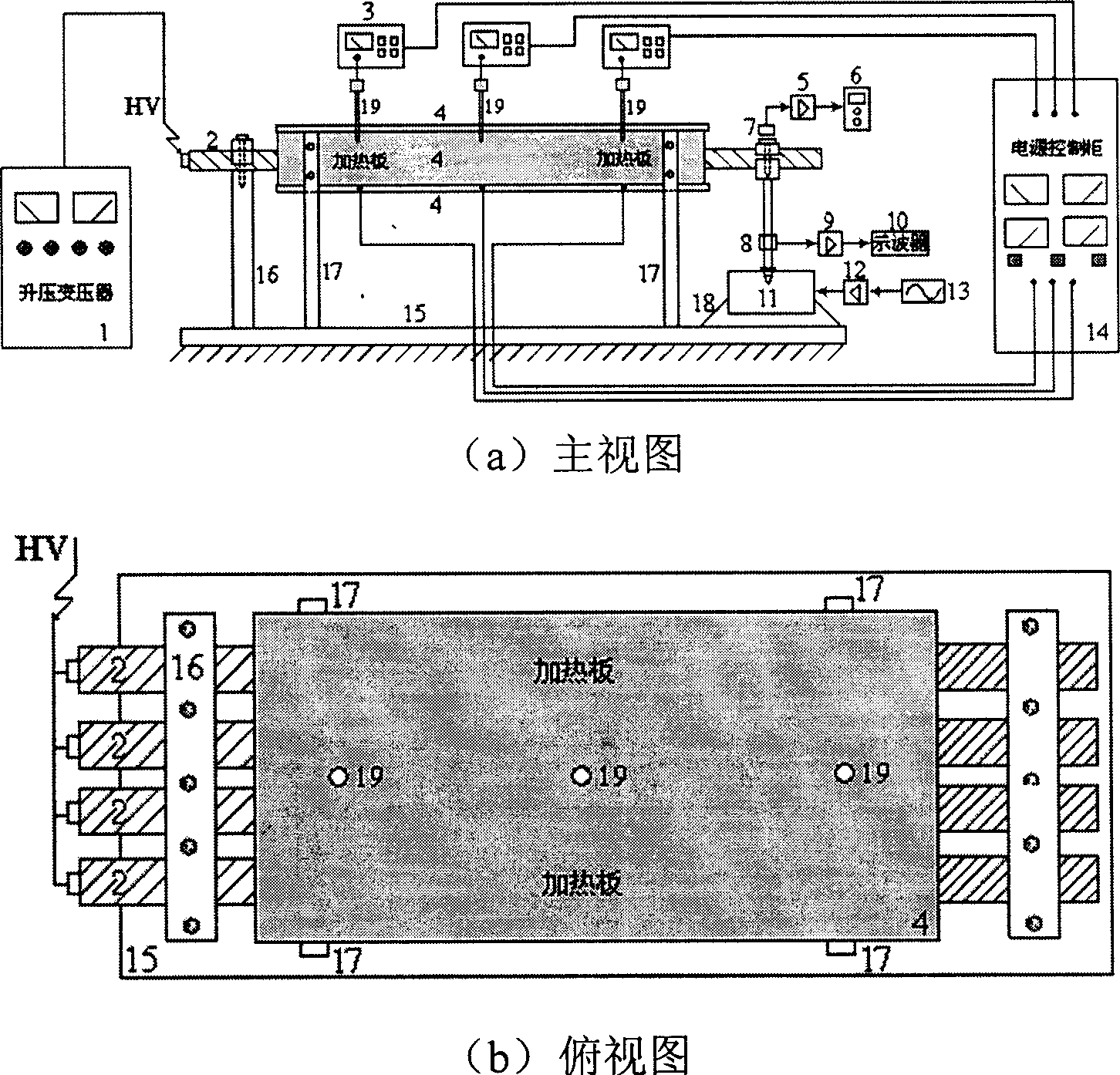

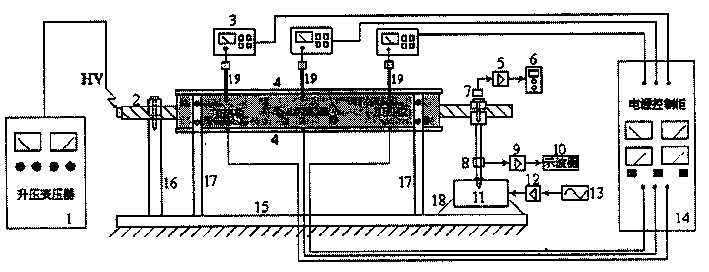

[0024] Referring to the accompanying drawings, the present invention is a multi-factor aging test device for the insulation of a large-scale generator or motor wire rod stator, which mainly includes a vibration table 15, a step-up transformer 1, a heating plate 4, a heating power control cabinet 14, a thermocouple 19, Temperature controller 3 , vibrator 11 , power amplifier 12 , signal generator 13 , acceleration sensor 8 , displacement sensor 7 , wire bar sample holder 16 and heating plate support 17 . The device can carry out multi-factor aging of various wire rods, and realize automatic protection and timing. The four aging parameters can be adjusted as needed to meet the aging requirements of different wire rods. System diagram as figure 1 shown.

[0025] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com