High-strength concrete interfacial agent and preparation method thereof

A technology of concrete and interface agent, which is applied in the field of building materials, can solve problems such as poor adhesion and waterproof performance, and achieve good balance, good water-reducing effect, and the effect of preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

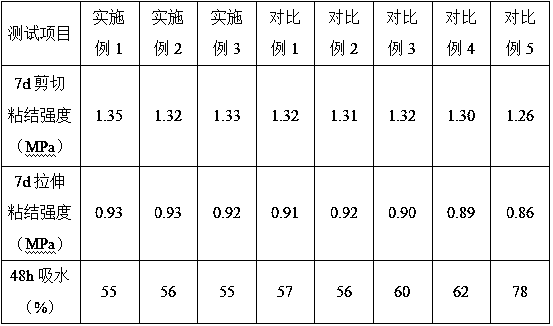

Examples

preparation example Construction

[0028] The preparation method of anti-pollution interface additive is:

[0029] (1) Take 4,4-diphenyl ether dicarboxylic acid and add N,N-dimethylformamide according to the mass ratio of 80~100:1~3, then add 2~5 times the mass of 4,4-diphenyl ether dicarboxylic acid Thionyl chloride, heated up to 70~80°C, stirred and mixed for 3~5h, distilled under reduced pressure, filtered, took the filter cake and added petroleum ether at a mass ratio of 2~5:10~15, let it stand for 20~50min, took the precipitate and dried it, To obtain dry matter, take methyl acrylate and add dropwise to 3,3'-di-tert-butyl-4,4'-diaminodiphenyl-4"-tert-butylphenyl in a mass ratio of 4~7:10~15 In methane, stir and mix at 70-80°C for 2-4 hours, and distill under reduced pressure to obtain a reduced-pressure distillate;

[0030](2) Take the vacuum distillate and add chloroform according to the mass ratio of 2~5:5~10, add pyridine with a mass ratio of 2~5% of the vacuum distillate, stir and mix for 20~30min to ...

Embodiment 1

[0041] The thermoplastic styrene-butadiene rubber SBS4402 is: the content ratio of styrene and butadiene is 40:60.

[0042] The preparation method of anti-pollution interface additive is:

[0043] (1) Take 4,4-diphenyl ether dicarboxylic acid and add N,N-dimethylformamide at a mass ratio of 80:1, then add thionyl chloride twice the mass of 4,4-diphenyl ether dicarboxylic acid, Stir and mix for 3 hours at 70°C, distill under reduced pressure, filter, take the filter cake and add petroleum ether at a mass ratio of 2:10, let it stand for 20 minutes, take the precipitate and dry it to obtain a dry product, take methyl acrylate and add it dropwise at a mass ratio of 4:10 into 3,3'-di-tert-butyl-4,4'-diaminodiphenyl-4"-tert-butylphenylmethane, stirred and mixed at 70°C for 2 hours, and distilled under reduced pressure to obtain a reduced-pressure distillate;

[0044] (2) Take the vacuum distillate and add chloroform at a mass ratio of 2:5, add pyridine with a mass ratio of 2% of th...

Embodiment 2

[0055] The thermoplastic styrene-butadiene rubber SBS4402 is: the content ratio of styrene and butadiene is 40:60.

[0056] The preparation method of anti-pollution interface additive is:

[0057] (1) Take 4,4-diphenyl ether dicarboxylic acid and add N,N-dimethylformamide at a mass ratio of 90:2, then add thionyl chloride three times the mass of 4,4-diphenyl ether dicarboxylic acid, Stir and mix for 4 hours at 75°C, distill under reduced pressure, filter, take the filter cake and add petroleum ether at a mass ratio of 4:12, let it stand for 35 minutes, take the precipitate and dry it to obtain a dry product, take methyl acrylate and add it dropwise at a mass ratio of 6:13 into 3,3'-di-tert-butyl-4,4'-diaminodiphenyl-4"-tert-butylphenylmethane, stirred and mixed at 75°C for 3 hours, and distilled under reduced pressure to obtain a reduced-pressure distillate;

[0058] (2) Take the vacuum distillate and add chloroform at a mass ratio of 3:7, add pyridine with a mass ratio of 4%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com