Novel vibration aging method

A vibration aging and aging technology, applied in the direction of fluid using vibration, can solve the problems of inability to realize real-time adjustment and low working efficiency of the vibration exciter, and achieve the effect of high processing efficiency, good effect and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

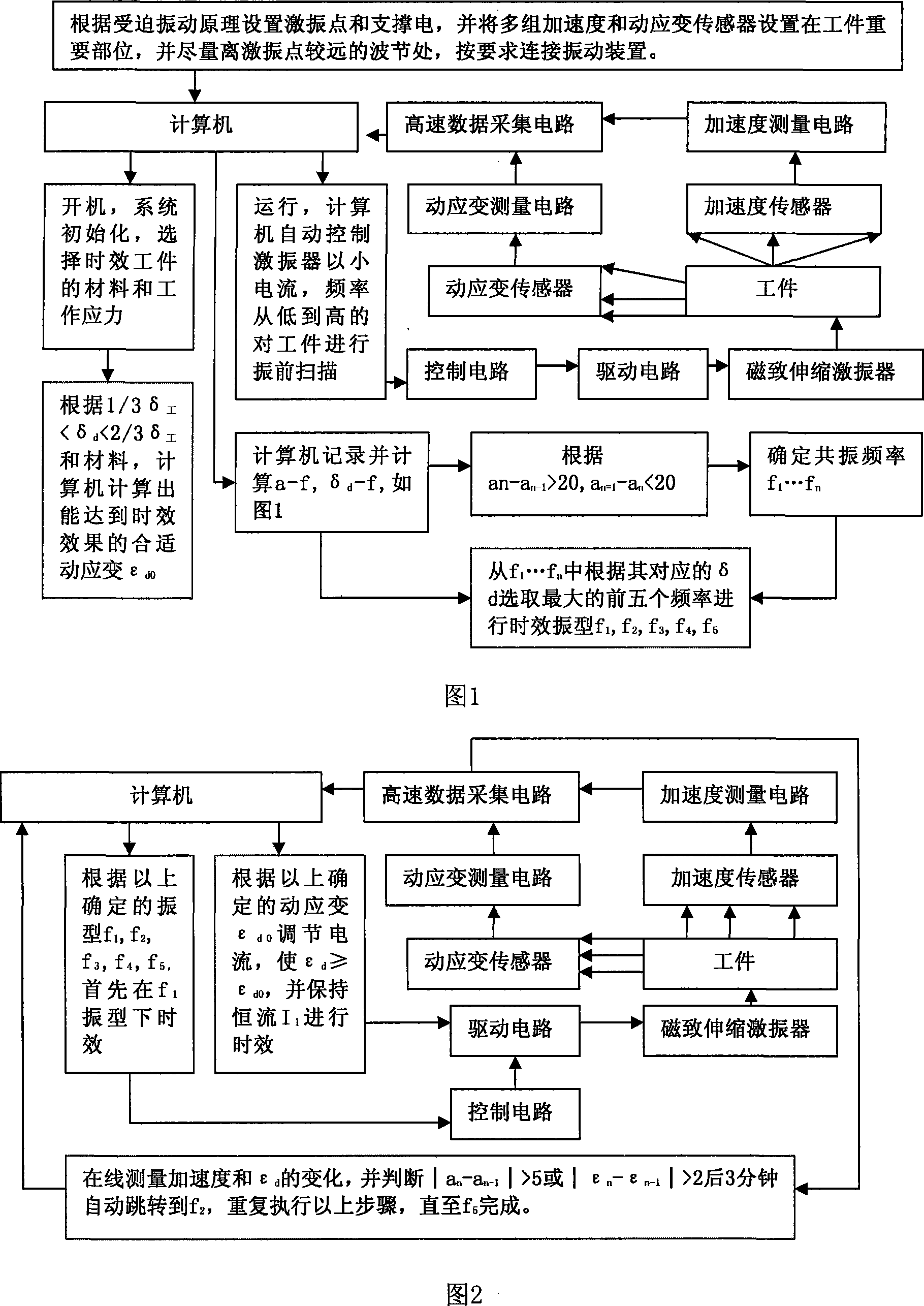

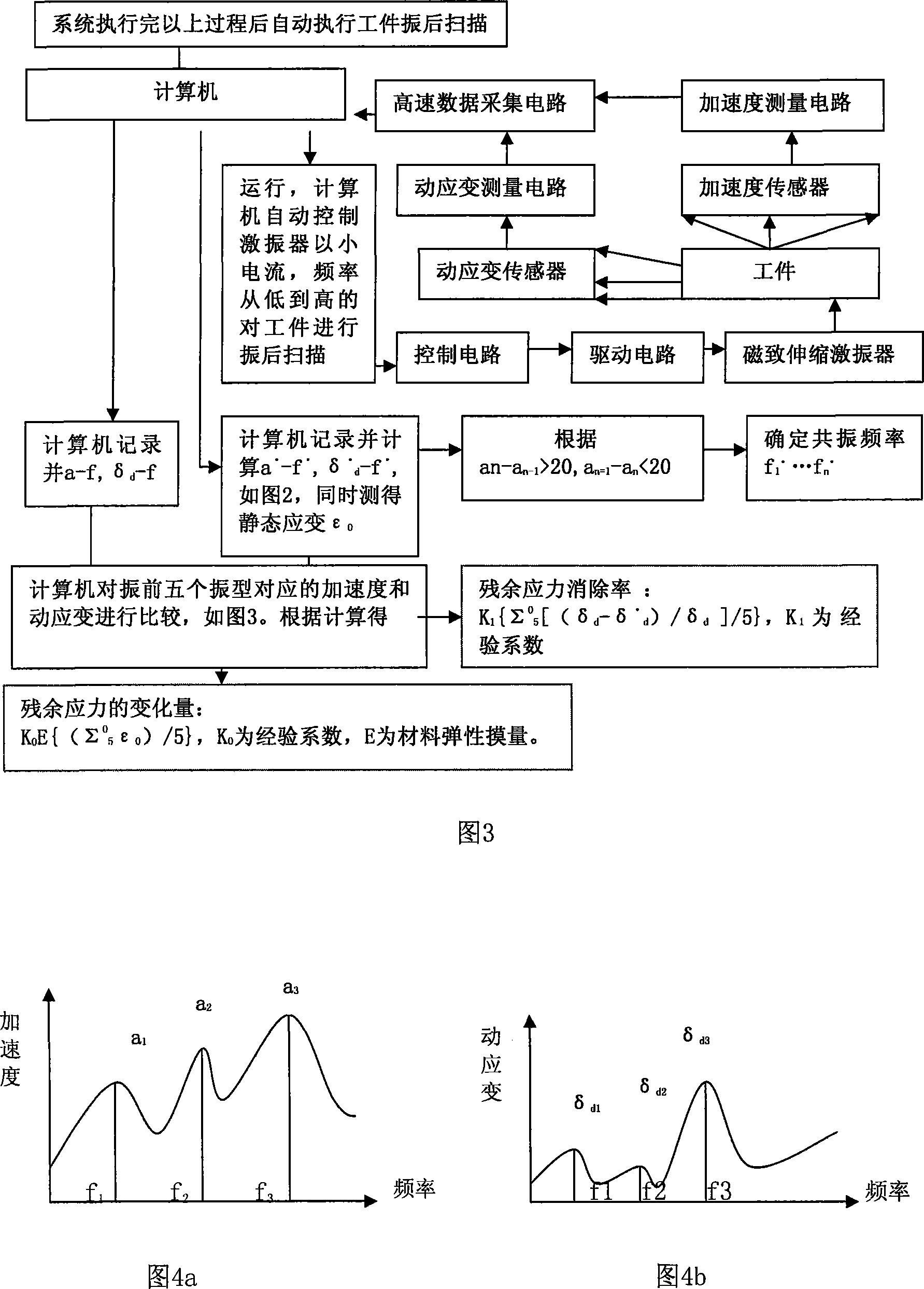

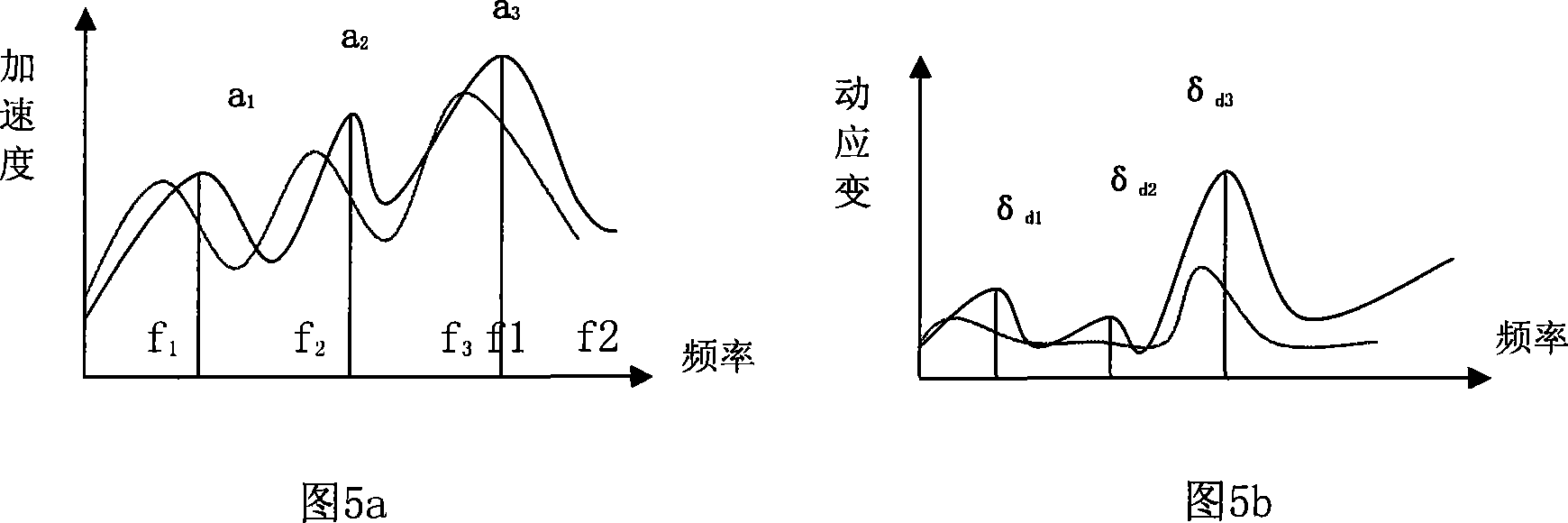

[0033]Fig. 1 is the system block diagram that the present invention adopts, and it mainly comprises control computer, magnetostrictive exciter, acceleration sensor and dynamic strain sensor, and magnetostrictive exciter is loaded on the surface of aging workpiece and exerts periodic exciting force , the acceleration sensor and the dynamic strain sensor are set on the aging workpiece to collect the acceleration and dynamic strain signals, and the acceleration sensor and the dynamic strain sensor are respectively sent to the data acquisition circuit through their measurement circuits, and the data collected by the data acquisition circuit is input to the control computer , the control computer analyzes and judges the mode shape and time that should be applied to the aged workpiece, and then adjusts the drive circuit current of the magnetostrictive vibrator through the output control signal of the control circuit, so that the magnetostrictive vibrator operates at the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com