Vibration aging method and device employing electric vibratory test system

A technology of electric vibration and vibration aging, which is applied in the field of mechanical processing, can solve the problems of low investment, unoptimized stress relief, and high difficulty in furnace temperature control, and achieves the effects of simple device structure, low operating cost, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

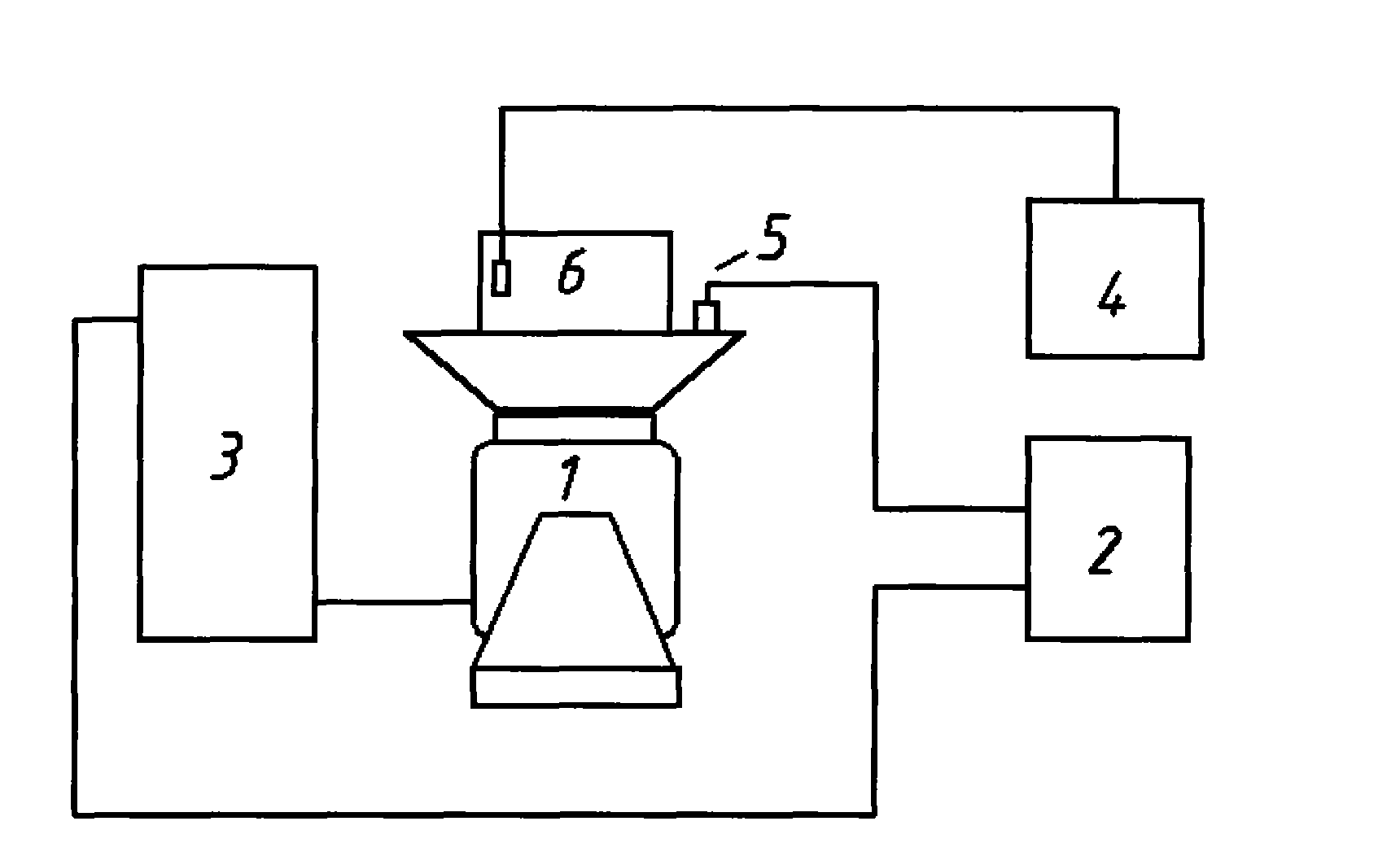

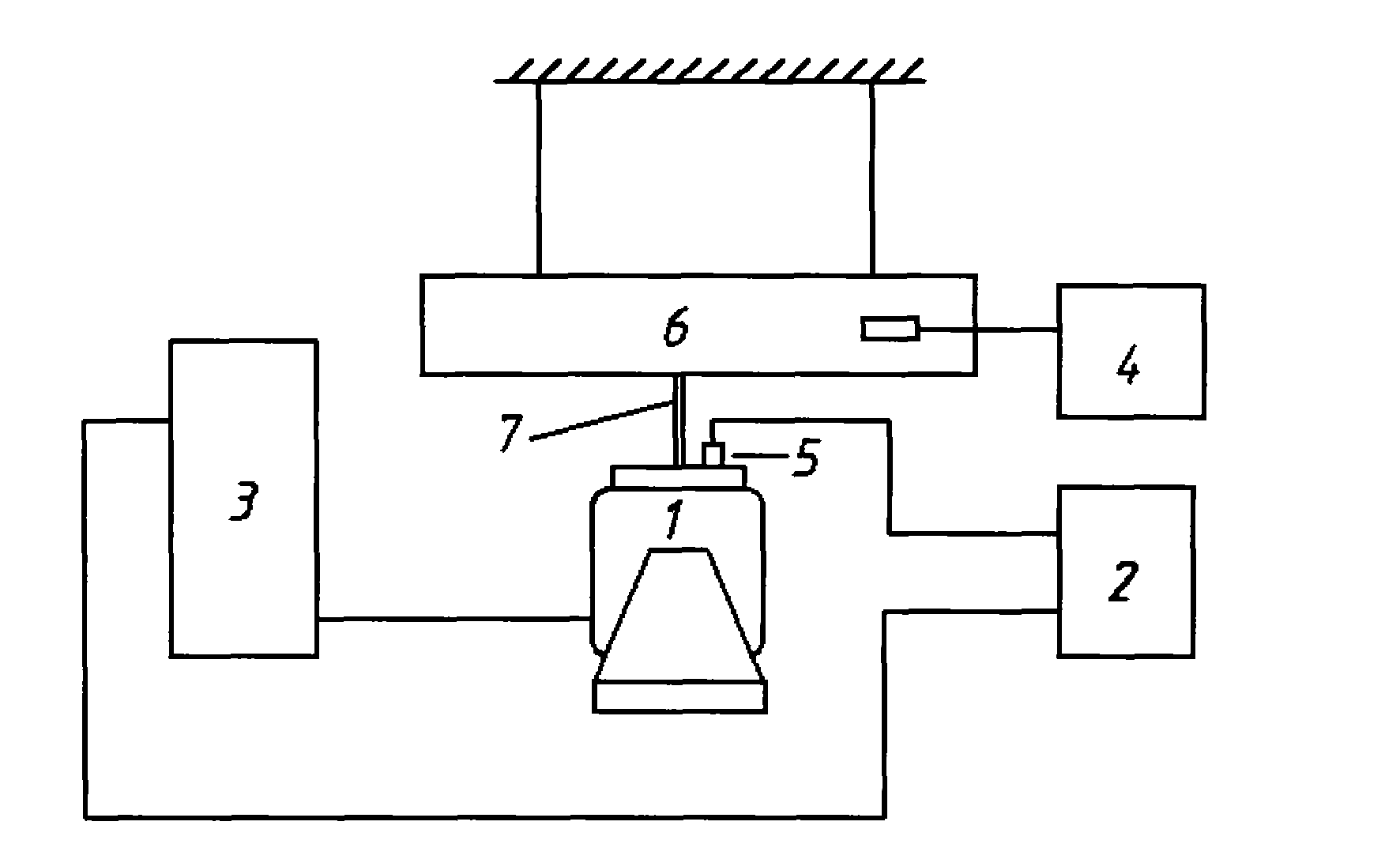

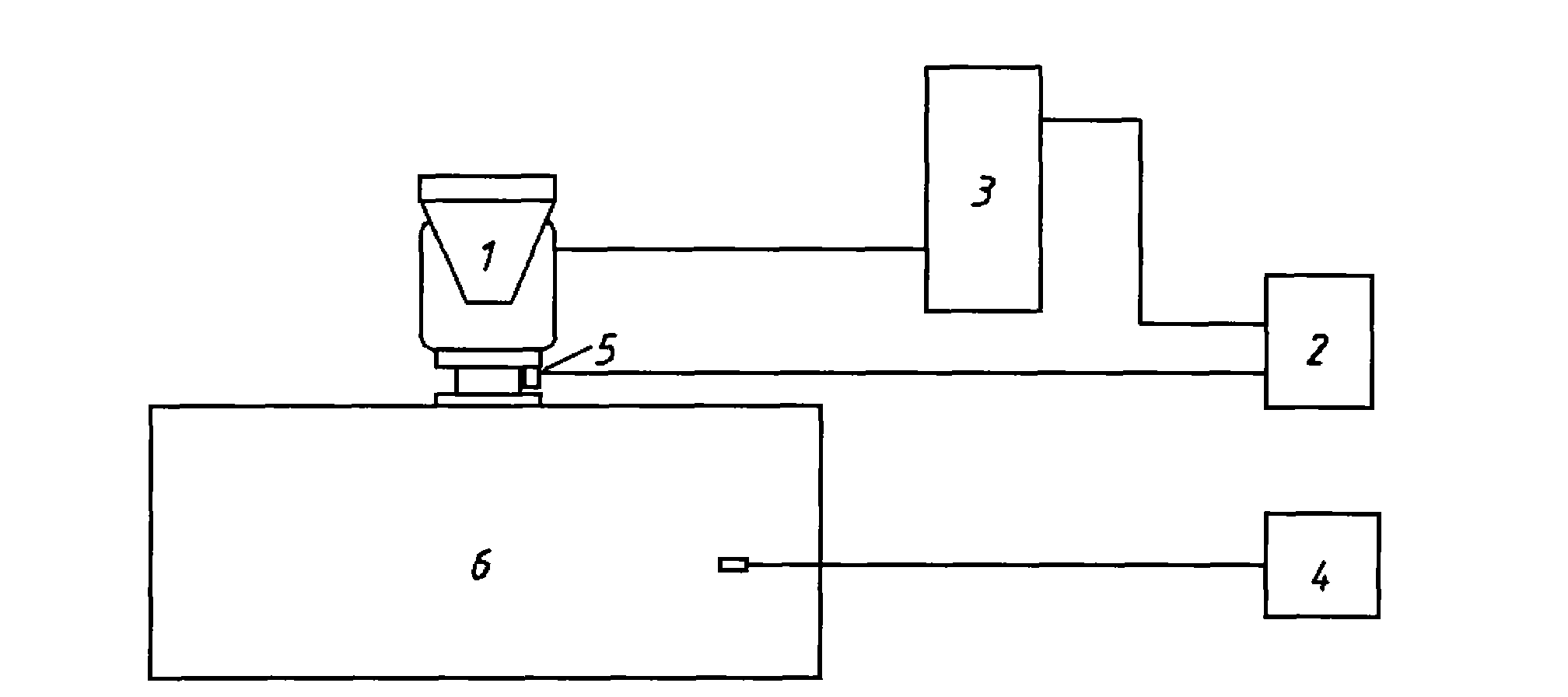

[0031] like figure 1 As shown, the device used in the vibration aging method using the electrodynamic vibration test system includes an electrodynamic shaker 1, a dynamic stress measurement system 4 and a vibration controller 2, wherein the electrodynamic shaker 1 is used to perform spectrum analysis on the workpiece, And provide excitation force; Dynamic stress measurement system 4 is used to measure the level of dynamic stress in workpiece 6; Vibration controller 2 is connected with electric vibration table 1 through a power amplifier 3, for adjusting the level of excitation force applied on the workpiece At the same time, the vibration controller 2 is also connected with an acceleration sensor 5 arranged on the table surface of the electric vibration table 1 to form a closed-loop control system.

[0032] The vibration aging method using the device is as follows:

[0033] Before the aging treatment of the workpiece, measure the residual stress in the workpiece, and determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com