Positioning device and lens module assembling apparatus

A technology for positioning devices and lens modules, applied in installation, instrumentation, optics, etc., can solve problems such as lower assembly yield, difficult cleaning, and damage to lens module components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

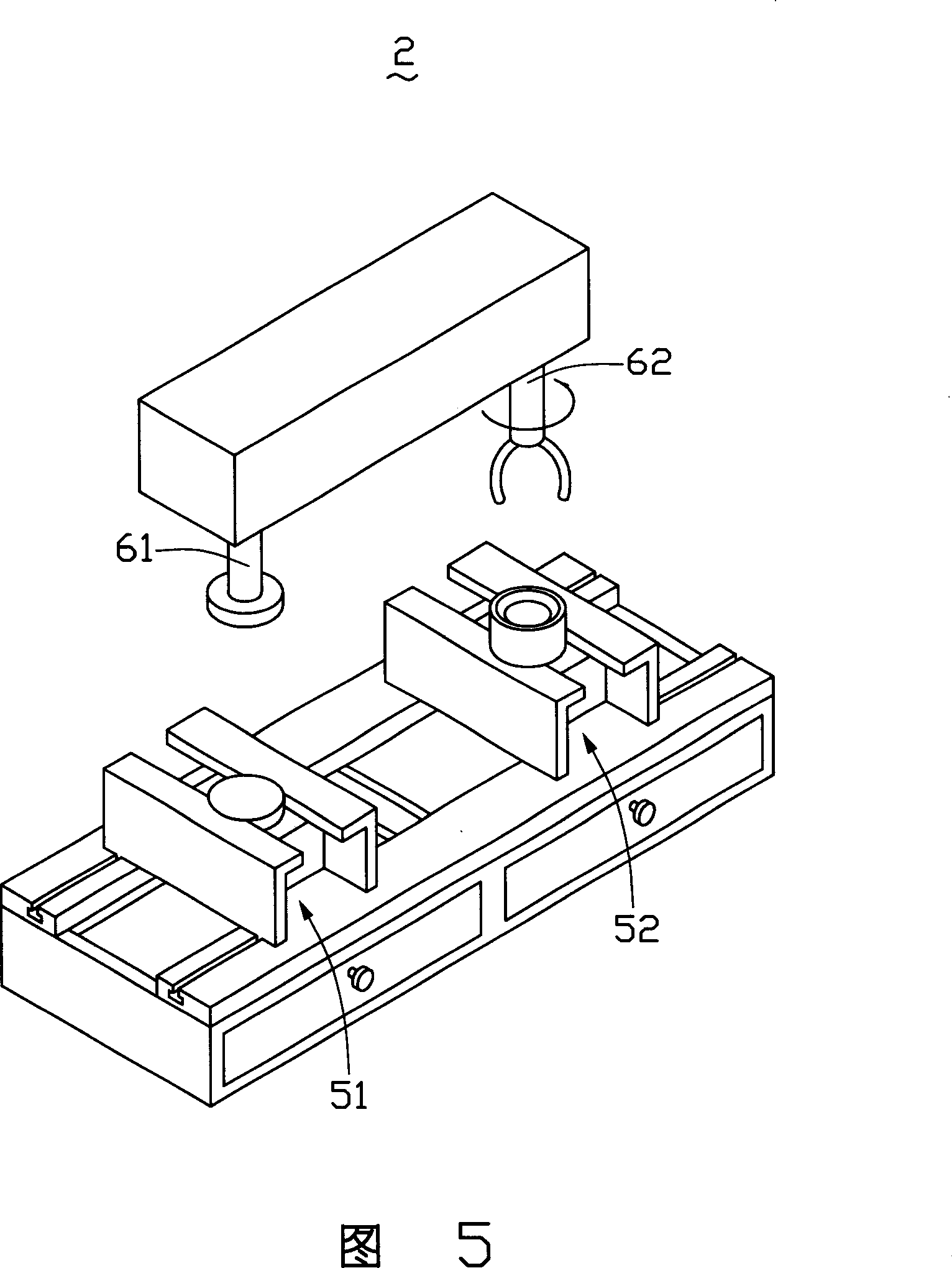

[0016] The positioning device and lens module assembly equipment provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

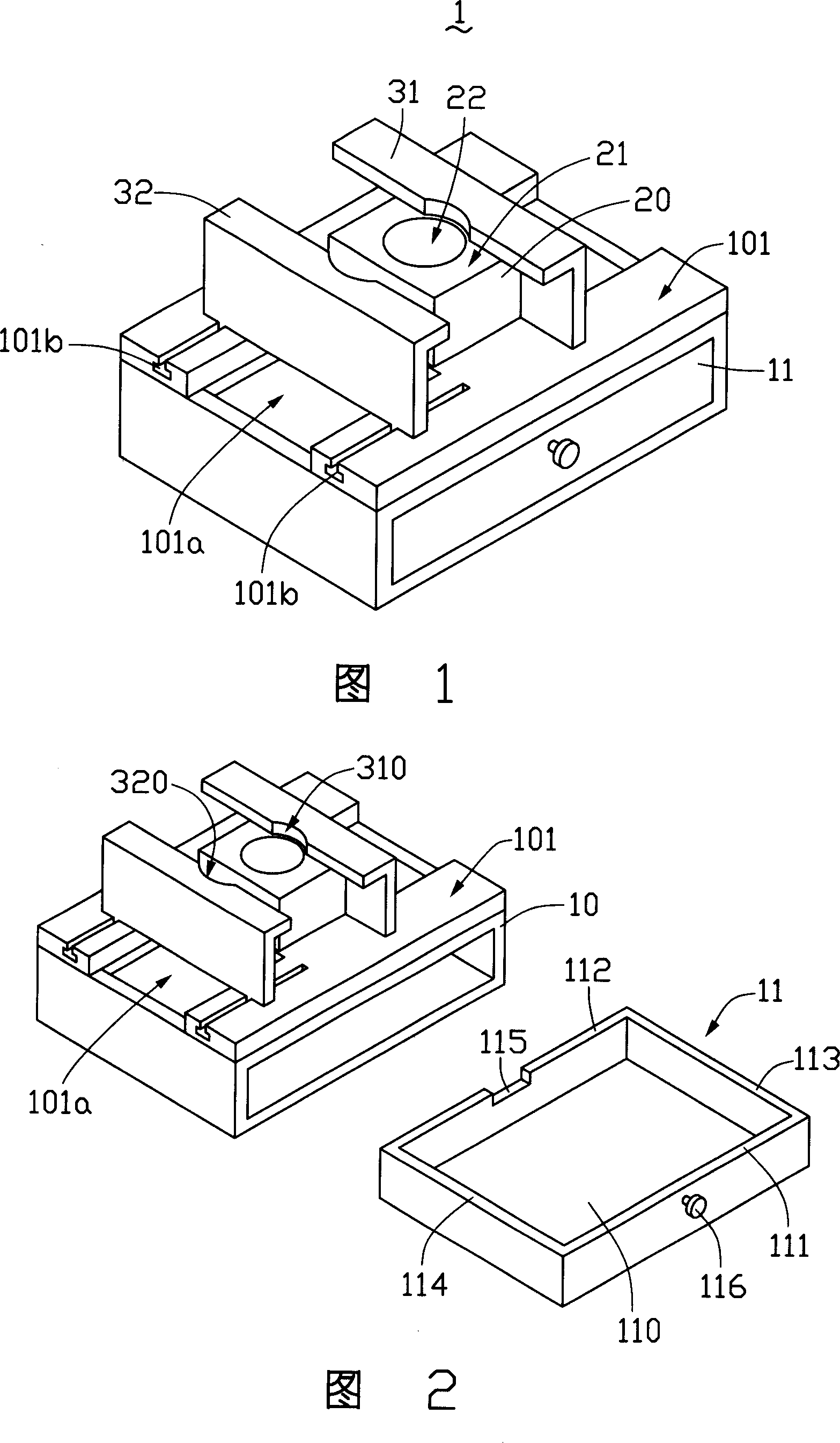

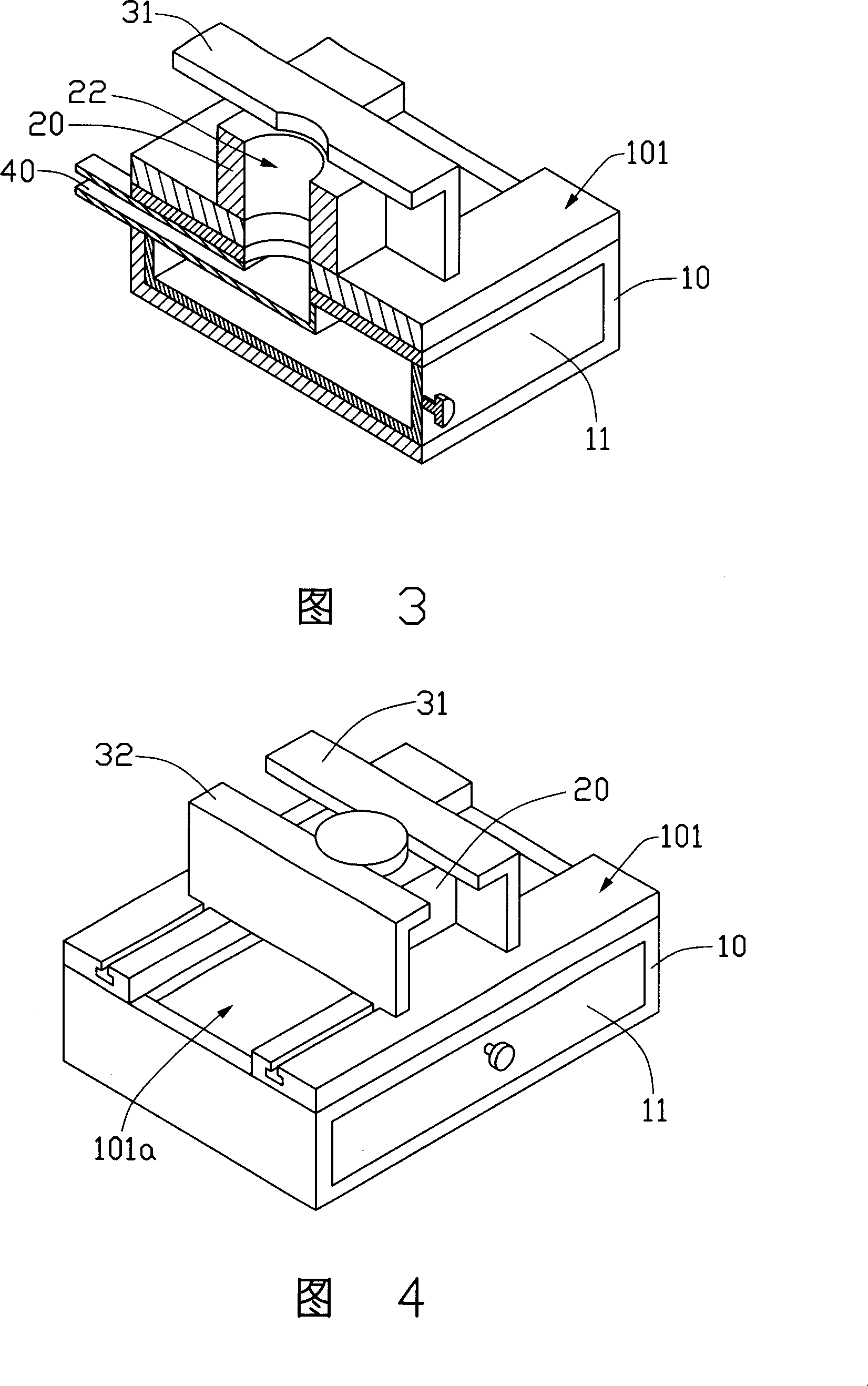

[0017] Please refer to FIGS. 1 to 3 together. The positioning device 1 provided by the embodiment of the present invention includes a base 10, a bearing body 20 disposed on the base 10, a first positioning block 31, and a The second positioning block 32 .

[0018] A storage drawer 11 is disposed under the surface 101 of the base 10 , and the surface 101 is provided with an opening 101 a communicating with the storage drawer 11 . The storage drawer 11 is a hollow square, including a square bottom 110, and two front and rear side walls 111, 112 and two left and right side walls 113, 114 vertically extending from the edge of the square bottom 110. The storage drawer 11 A groove 115 is opened on the rear side wall 112 , and a handle 116 is protruded from the outer surface of the front side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com