Water pump assembling equipment and water pump assembly line

An assembly equipment and assembly line technology, which is applied in the direction of assembly machines, metal processing equipment, and devices for coating liquid on the surface, can solve problems such as low work efficiency, unfavorable product assembly quality, and uncertainty, so as to improve efficiency and improve The effect of assembly efficiency and assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

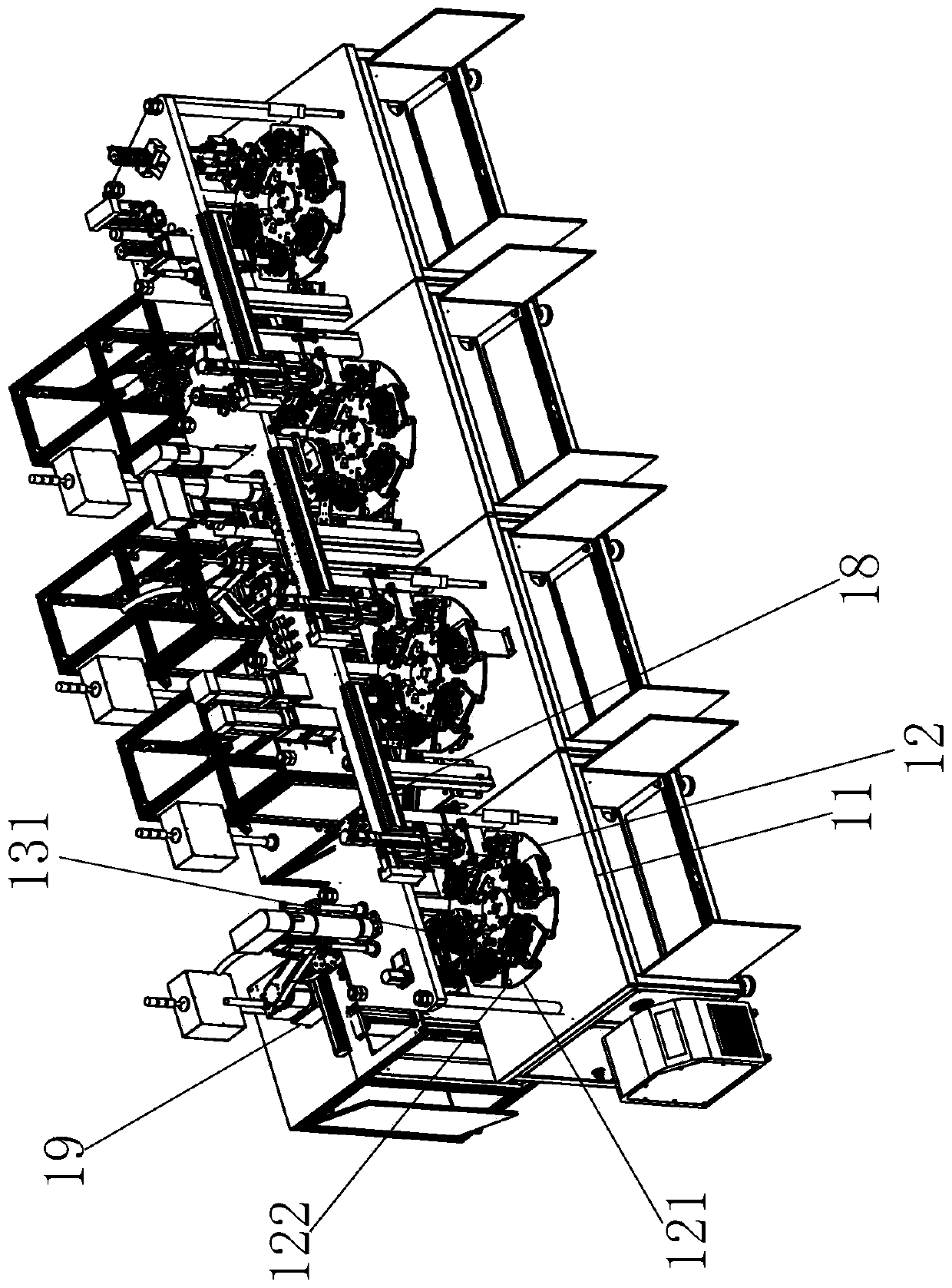

Embodiment 1

[0034] It should be noted that the water pump assembly equipment of this embodiment can press-fit the coupling bearing into the pump body from top to bottom.

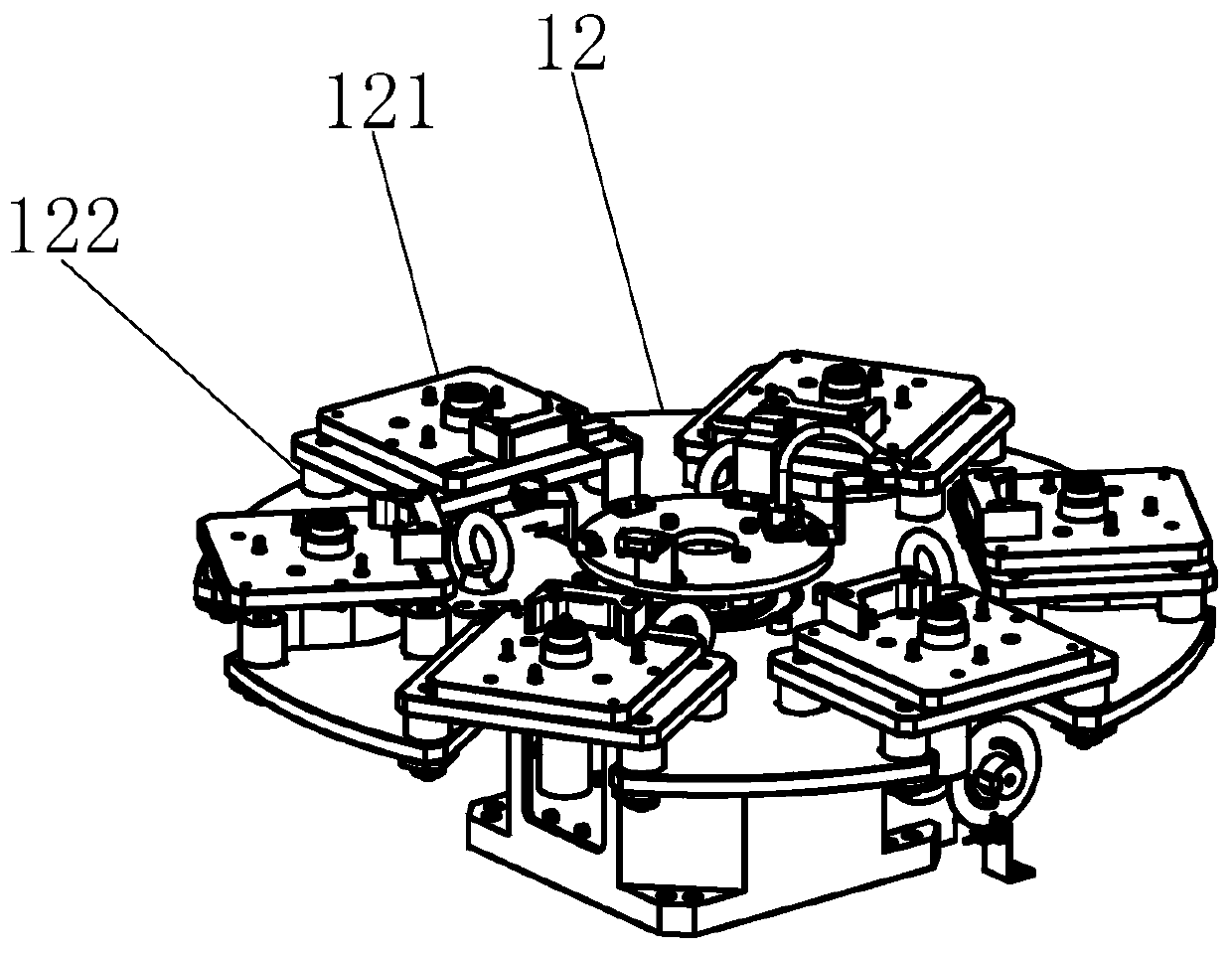

[0035] Such as Figure 4 As shown, the transfer assembly 14 of this embodiment is different from the above, the difference is that the transfer assembly 14 of this embodiment is located above the turntable 12, and it includes a rotating arm 141, and the two ends of the rotating arm 141 A clamping assembly 16 is provided at the end, and the clamping assembly 16 is preferably a clamping cylinder. The clamping assembly 16 can clamp the shaft coupling bearing to be assembled. In this embodiment, the shaft coupling bearing is installed by pressing down. Assembly 131 can move downward to press-fit the shaft coupling bearing on the bearing hole corresponding to the bearing of the pump body; specifically, the press-fit assembly 131 includes a pressure head that can move vertically, and the pressure head is connected Telescopic...

Embodiment 2

[0040] It should be noted that the water pump assembly equipment of this embodiment can press-fit the water seal into the pump body from bottom to top.

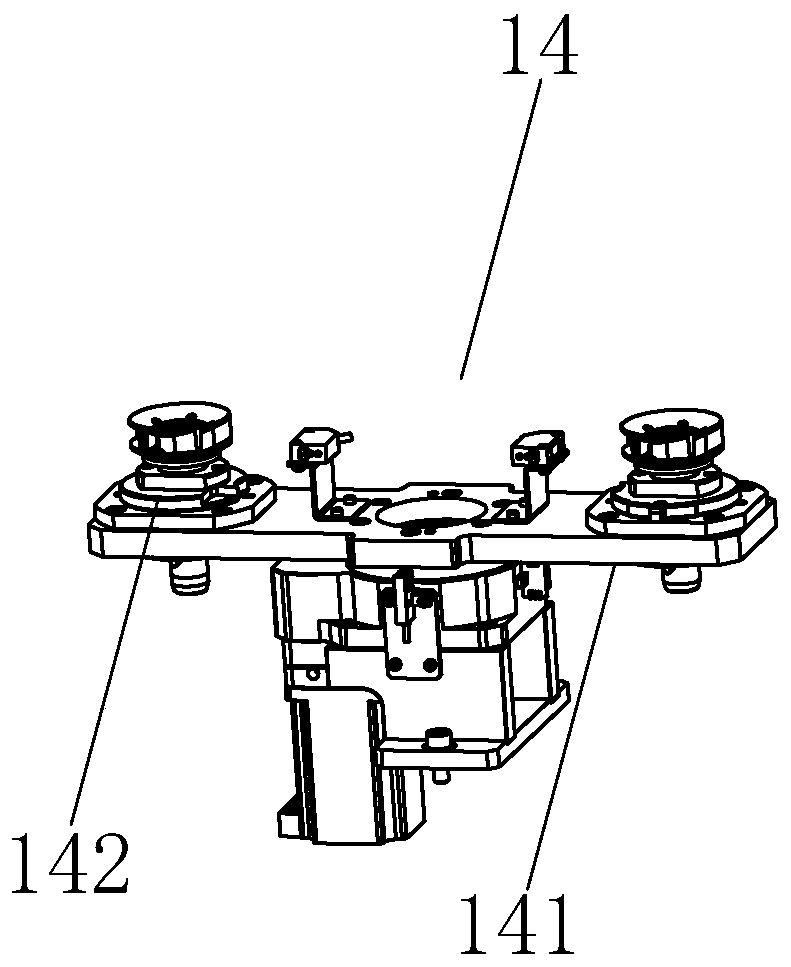

[0041] Such as Figure 7 As shown, in this embodiment, the press assembly 131 includes a pressure head, and the top assembly 132 includes an upper head, and the pressure head can move downward to crimp the pump body to ensure that the pump body is relatively fixed during the assembly process, ensuring that Assembling accuracy, the upper head can move upwards and drive the water seal on the support seat 142 to pass through the turntable 12, and press the water seal into the pump body; specifically, the press-fit assembly 131 and the upper head are connected with vertical Telescopic cylinder; the transfer assembly 14 is arranged in the area between the top assembly 132 and the turntable 12, in this embodiment, the transfer assembly 14 can transfer the water seal to the area between the top assembly 132 and the turntable 12 , T...

Embodiment 3

[0049] It should be noted that the water pump assembly equipment of this embodiment can press-fit the flange into the pump body from top to bottom.

[0050] It should be noted that, for the convenience of description, in this embodiment, the moving plate is described as the first moving plate 303 , the limiting rod is described as the first limiting rod 304 , and the pressing rod is described as the first pressing rod 312 .

[0051] Such as Figure 7 As shown, in this embodiment, the top-mounting assembly 132 is a top-mounting seat, and the press-fitting assembly 131 includes a press-fitting head 302 that can move vertically and an adsorption assembly arranged in the press-fitting head 302 to absorb The assembly can attach the flange to the lower end of the press-fitting head 302. Specifically, the press-fitting head 302 is connected with a driver, which can be a servo motor and converts the rotational output into a linear output through a worm gear structure to drive The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com