Automatic abrasive disc switch device of metallographic grinder

An automatic switching, metallographic grinding technology, applied in grinding devices, grinding drive devices, grinding machine tools, etc., can solve the problems of increasing the labor time and labor intensity of experimenters, wasting sandpaper raw materials, etc., to reduce labor time and labor intensity. , The effect of simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

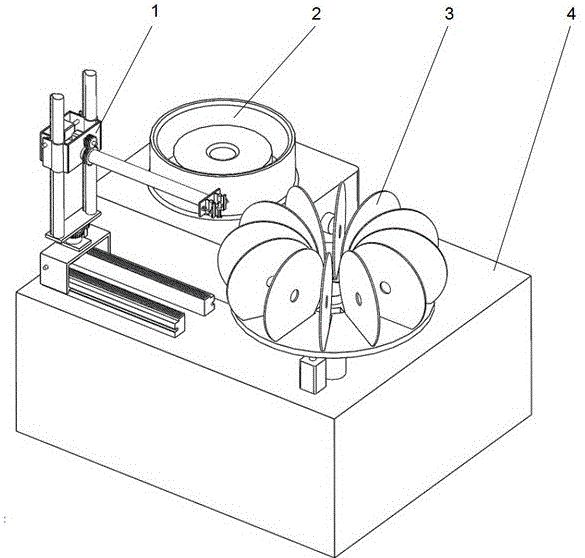

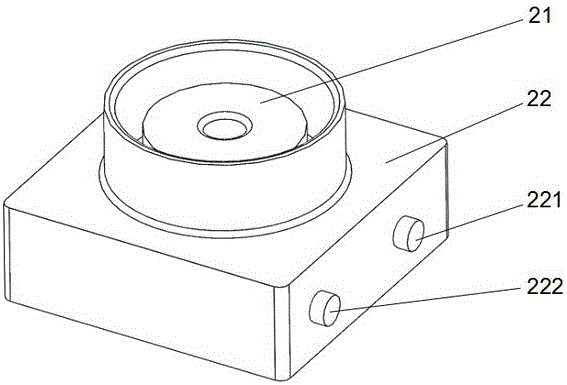

[0042] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, this embodiment is composed of an automatic disk changing system 1, a grinding machine console 2, a disk storage mechanism 3 and a platform 4, and the automatic disk changing system 1 and the grinding machine console 2 are respectively fixed on the platform 4 On, the disk library mechanism 3 is set on the platform;

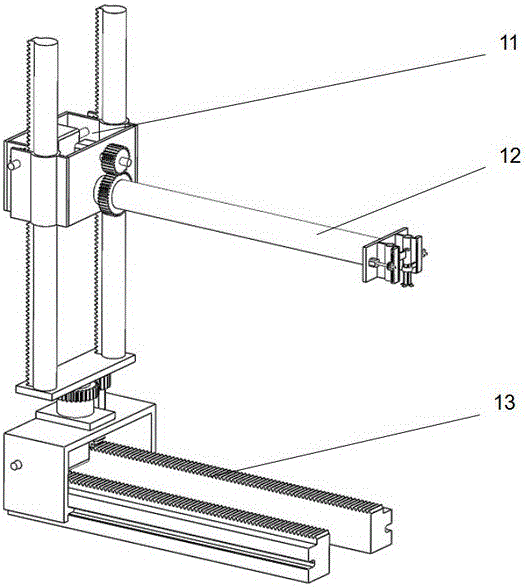

[0043] The automatic disk changing system 1 includes a vertical control mechanism 11, a clamping mechanism 12 and a base control mechanism 13, the vertical control mechanism 11 is fixedly arranged on the base control mechanism 13, and the rear end of the clamping mechanism 12 is arranged on the vertical control mechanism 11;

[0044] The vertical control mechanism 11 comprises a first vertical rack track 1101, a second vertical rack track 1102, a first stepping motor 1103, a first vertical slider 1104, a second vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com