Thin walled cylinder girth laser welding tong

A technology for laser welding fixtures and thin-walled cylinders, which is applied to laser welding equipment, welding equipment, welding equipment, etc., can solve the problem of inability to complete the accurate splicing and clamping of two thin-walled cylinders to be welded, and the inability to adapt to the requirements of laser welding of thin-walled cylinder welds, The problem of loading and unloading of longer cylinders is not considered, and the effect of reliable and convenient clamping, high efficiency and accurate positioning is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

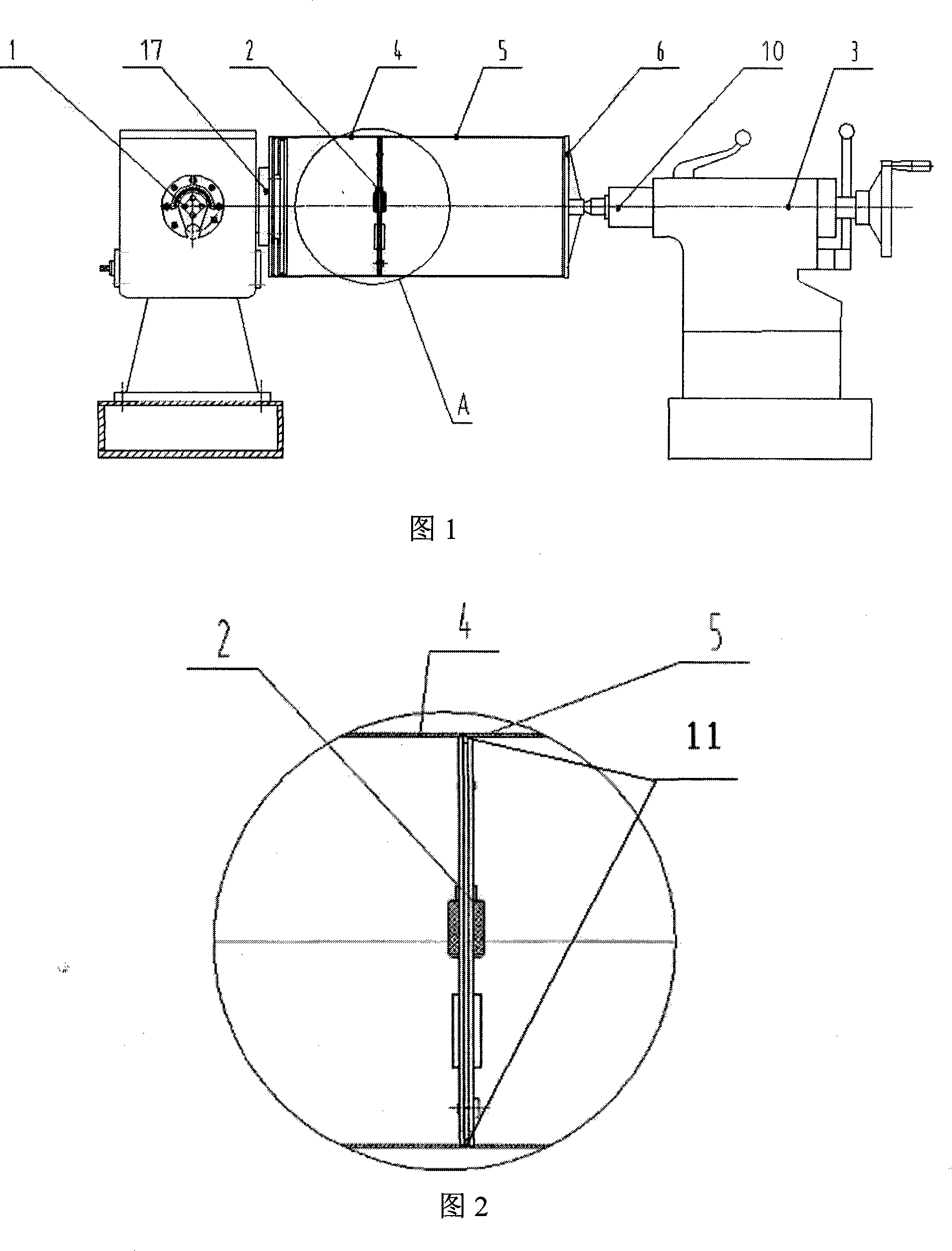

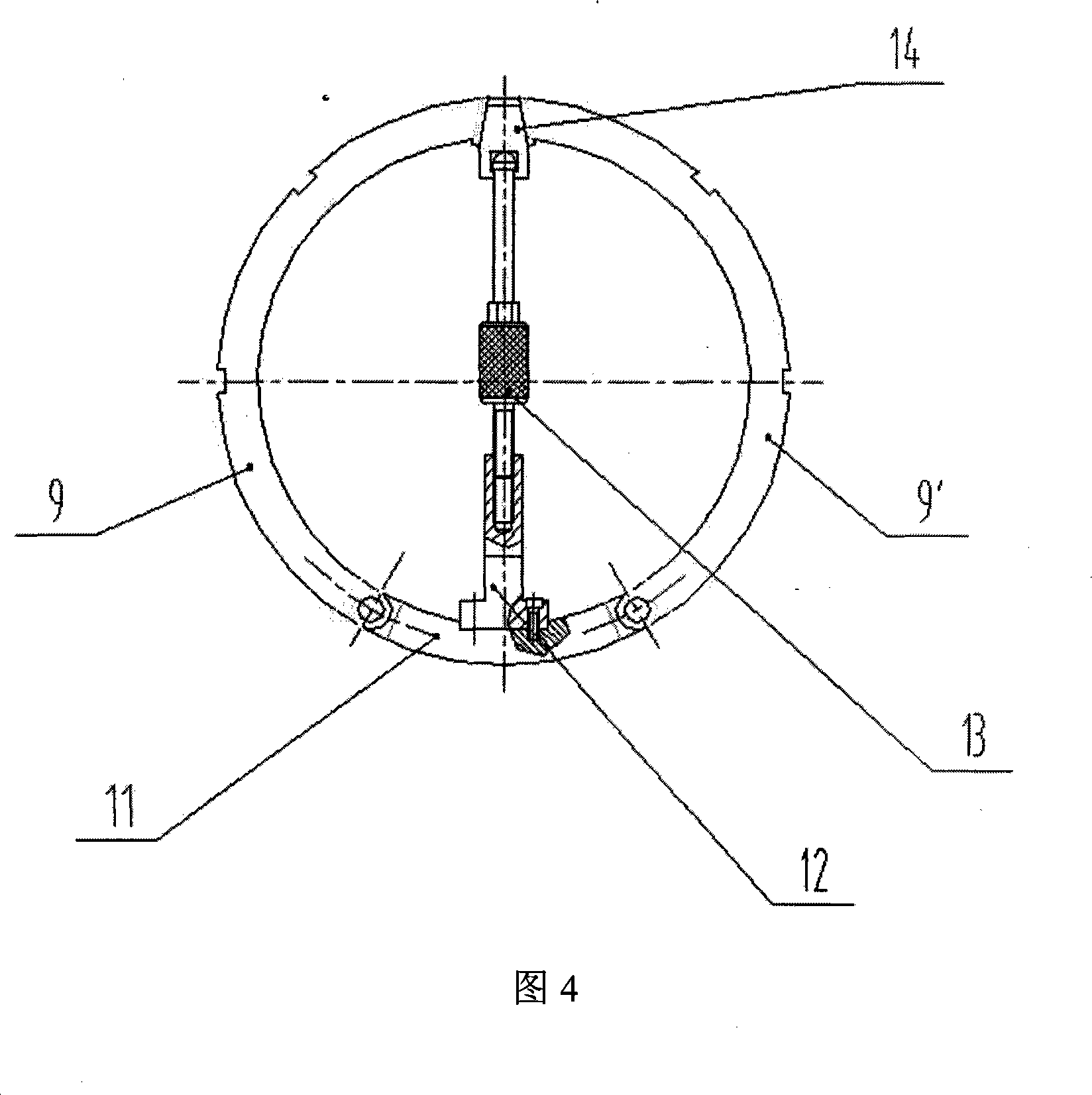

[0015] As shown in FIG. 1 and FIG. 2 , the thin-walled circular circular seam laser welding fixture of the present invention includes a head frame 1 , an expansion ring 2 , a machine tail frame 3 and a top plate 6 .

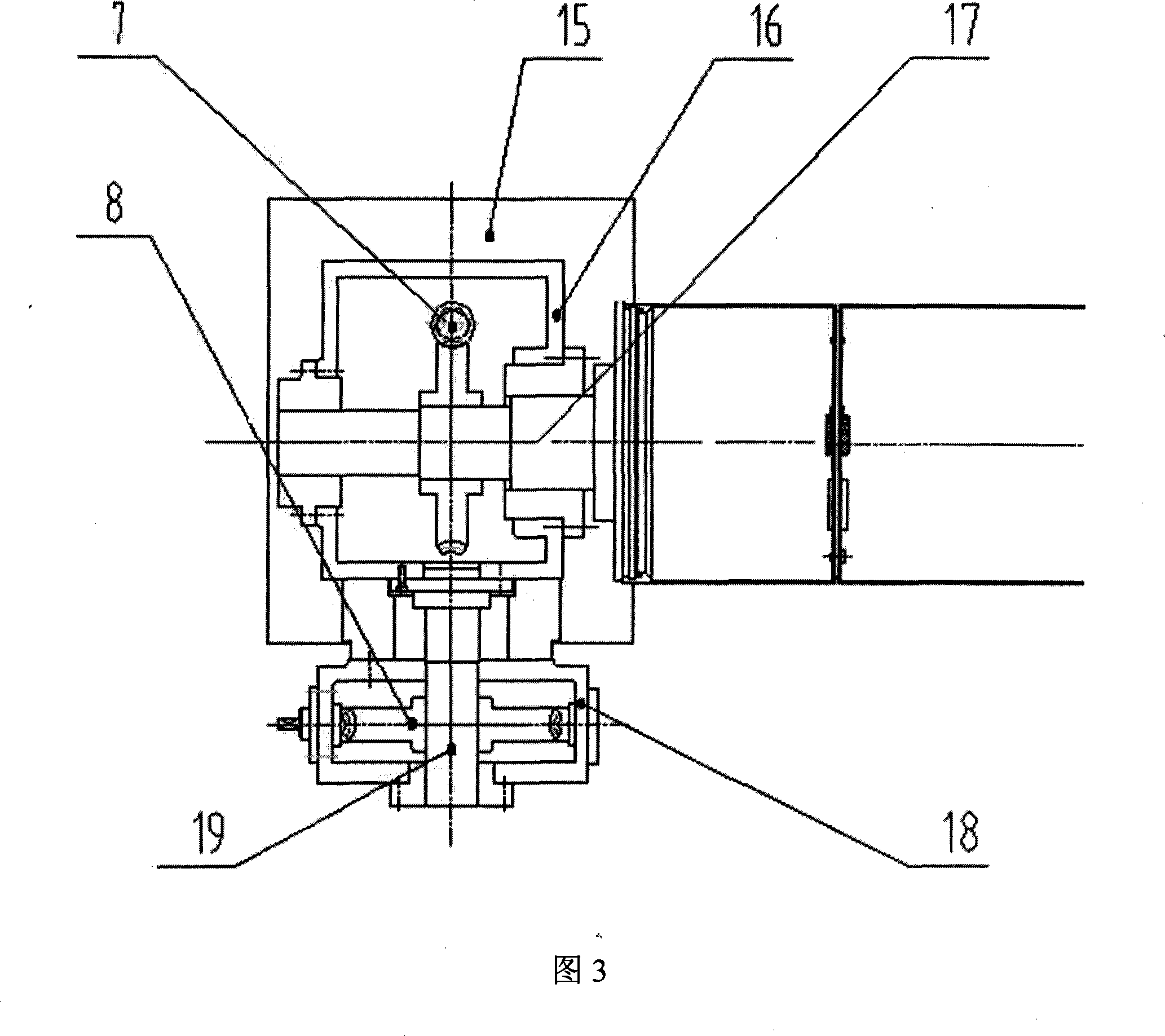

[0016] As shown in FIG. 3 , the headstock 1 is mainly composed of a base 15 , a headstock 16 , a main shaft 17 , a main shaft worm and gear mechanism 7 , an overturning box 18 , an overturning worm and gear mechanism 8 and an overturning shaft 19 . Turning box 18 is fixedly connected on the base 15, and turning shaft 19 is installed in the turning box 18, and the worm gear of turning over worm gear mechanism 8 is fixedly connected with turning shaft 19, and its worm is installed on the turning box 18. The turning shaft 19 is driven to realize the turning of the turning shaft 19 around its own axis. The spindle box 16 is fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com