Large-scale full-turning offshore platform crane

An offshore platform and full-slewing technology, which is applied to cranes, ships, cargo handling equipment, etc., can solve the problems of occupying deck space, etc., and achieve the effect of improving use efficiency, simple appearance, and simple appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

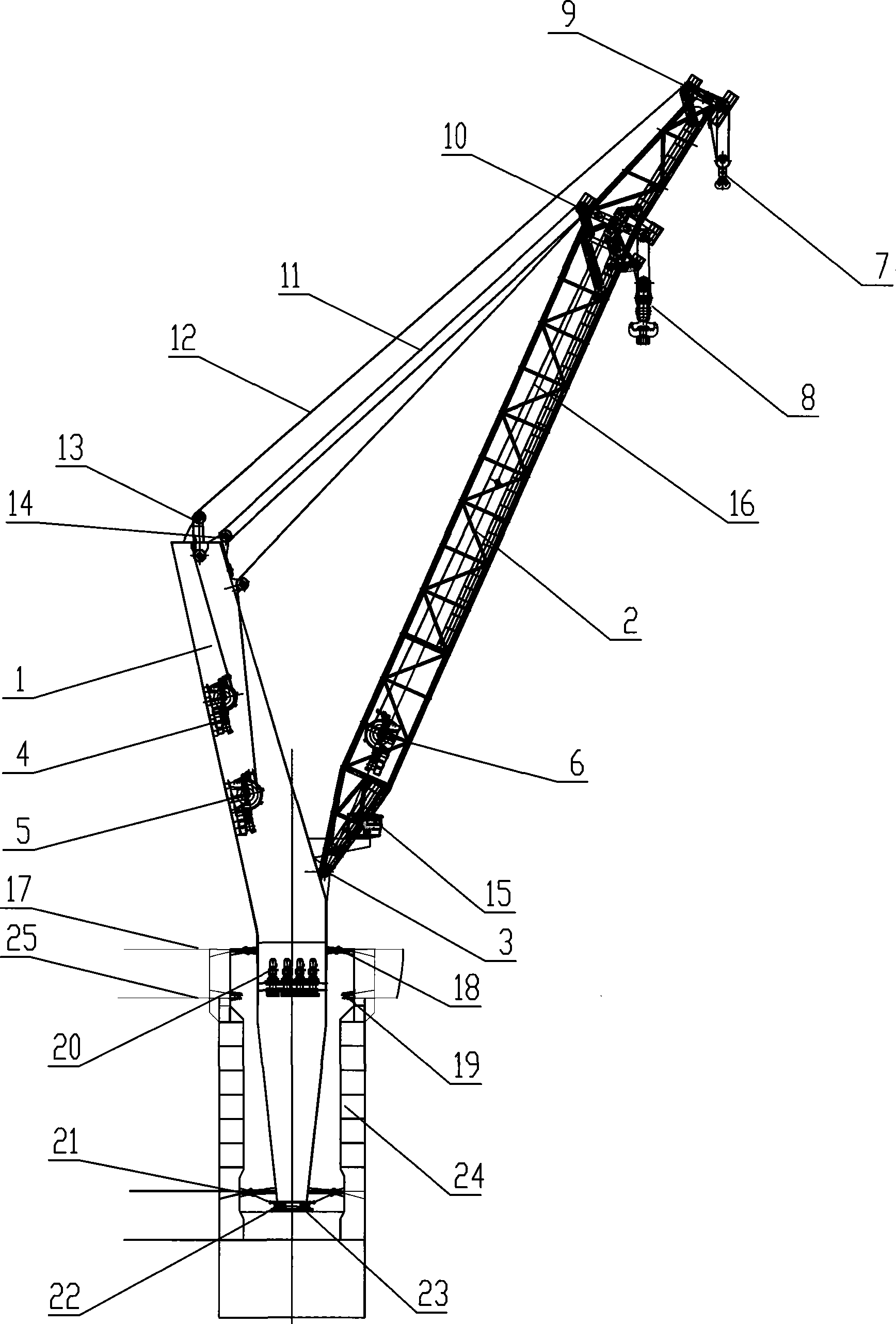

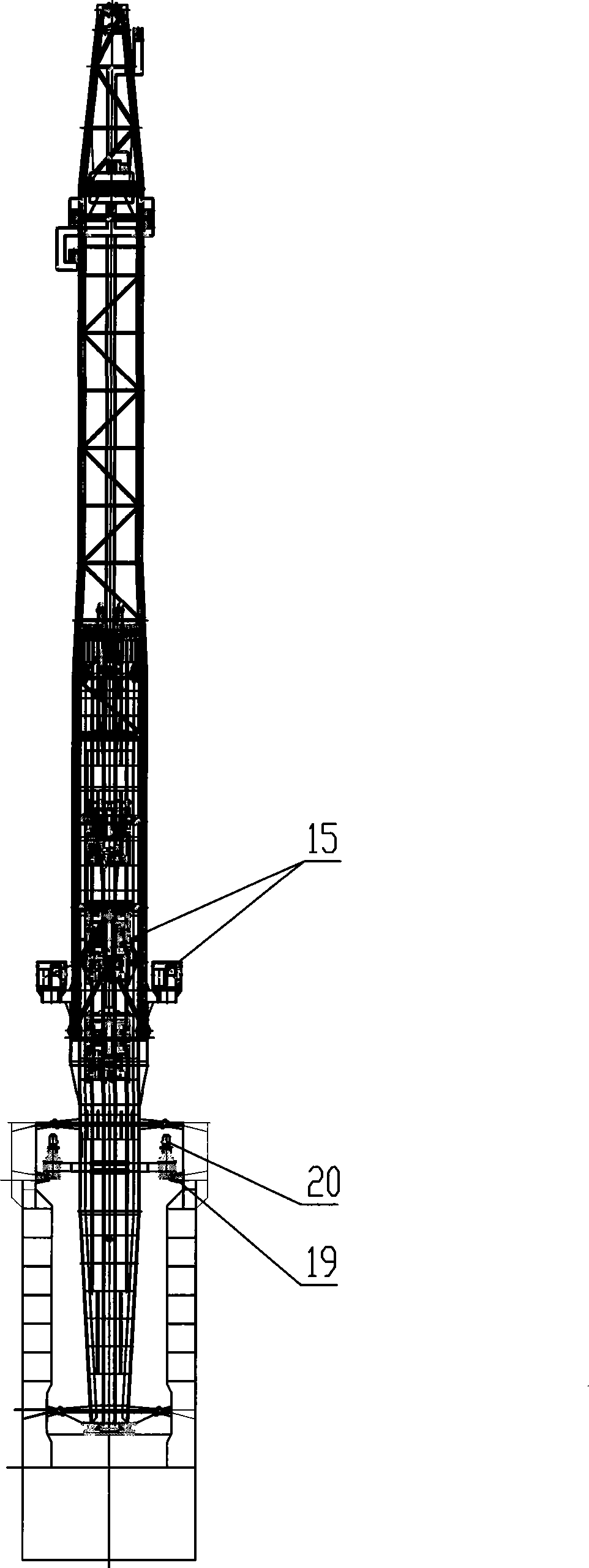

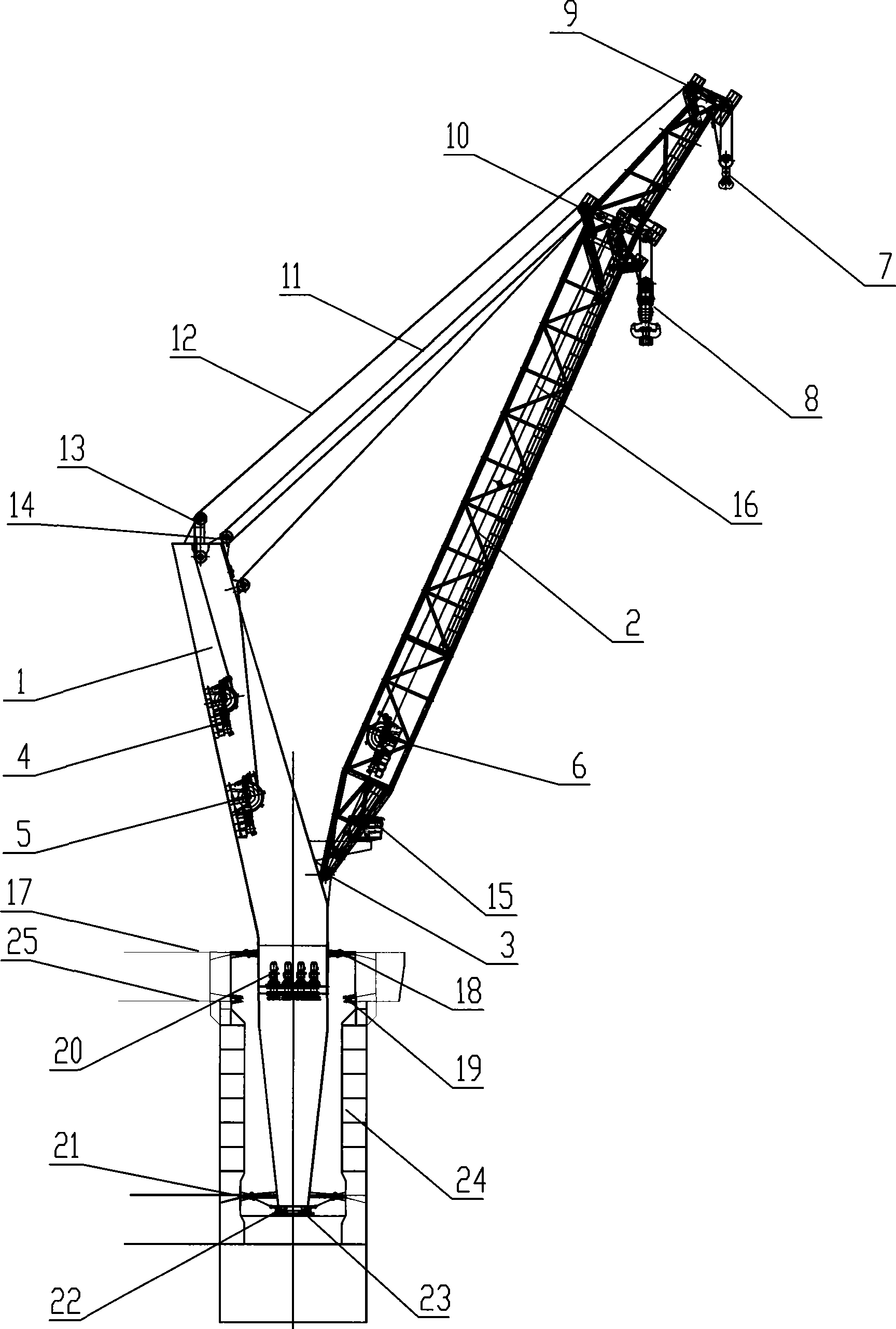

[0012] The specific embodiment of the present invention is shown in the accompanying drawings, consisting of a rotating column 1, a jib 2, a main hoisting hoist 6, an auxiliary hoisting hoist 4, a jib luffing hoist 5, a slewing bearing drive mechanism, a main hook 8, an auxiliary Parts such as suspension hook 7, driver's cab 15 are formed. The jib 2 is connected to the middle part of the rotating column 1 through the hinge point 3 installed at the root, and the lower half of the rotating column 1 is located below the main deck 17, and is connected with the semi-submersible platform 24 through a slewing bearing drive mechanism. The slewing bearing driving mechanism is composed of an upper radial bearing 18, a pin tooth 19, a three-in-one reducer 20, a lower radial bearing 21, a centripetal thrust bearing 22 and a rubber bearing 23. The middle part of the rotating column 1 is equipped with an upper radial bearing 18 near the main deck 17, and the lower part of the rotating colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com