Automated pressure casting system

A die-casting machine and moving mold technology, applied in the field of automatic die-casting system, can solve problems such as unsuitability, personal injury of employees, easy blockage or breakage of copper pipes, etc., and achieve the effect of improving the qualified rate of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] An automatic die-casting system includes a control device and a mechanical device.

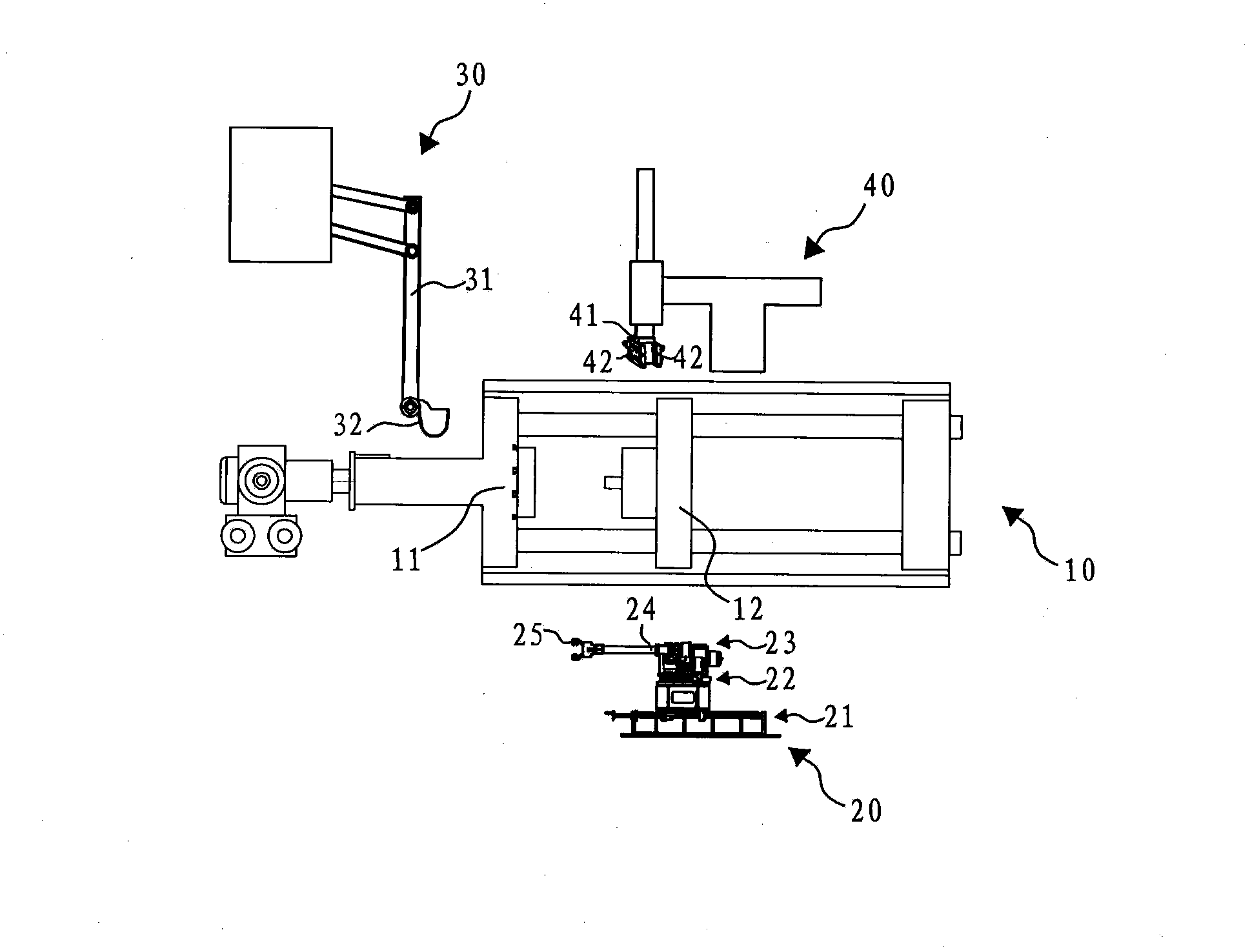

[0031] Please refer to figure 1 As shown, it has shown the specific structure of the preferred embodiment of the present invention, and the mechanical device includes a die-casting machine 10, a reverse take-out machine 20, a soup feeding machine 30 and a spraying machine.

[0032] Wherein, the die-casting machine 10 is provided with a fixed mold 11 and a movable mold 12 , and the reverse extractor 20 is arranged on the side of the movable mold 12 . This reverse take-out machine 20 is provided with horizontal moving mechanism 21, rotating mechanism 22 and arm driving mechanism 23; This rotating mechanism 22 is installed on the horizontal moving mechanism 21, and this arm driving mechanism 23 is installed on the rotating mechanism 22; The arm driving mechanism 23 is provided with a manipulator 24 for automatically clamping products. The end of the manipulator 24 is provided with a float...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com