Clamp for preparing graphene and method for preparing graphene

A graphene and jig technology, applied in the field of graphene preparation, can solve the problems of small number of single growth batches, waste of resources, poor quality of graphene, etc., to ensure uniformity and stability, improve production efficiency and yield , The effect of minimizing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

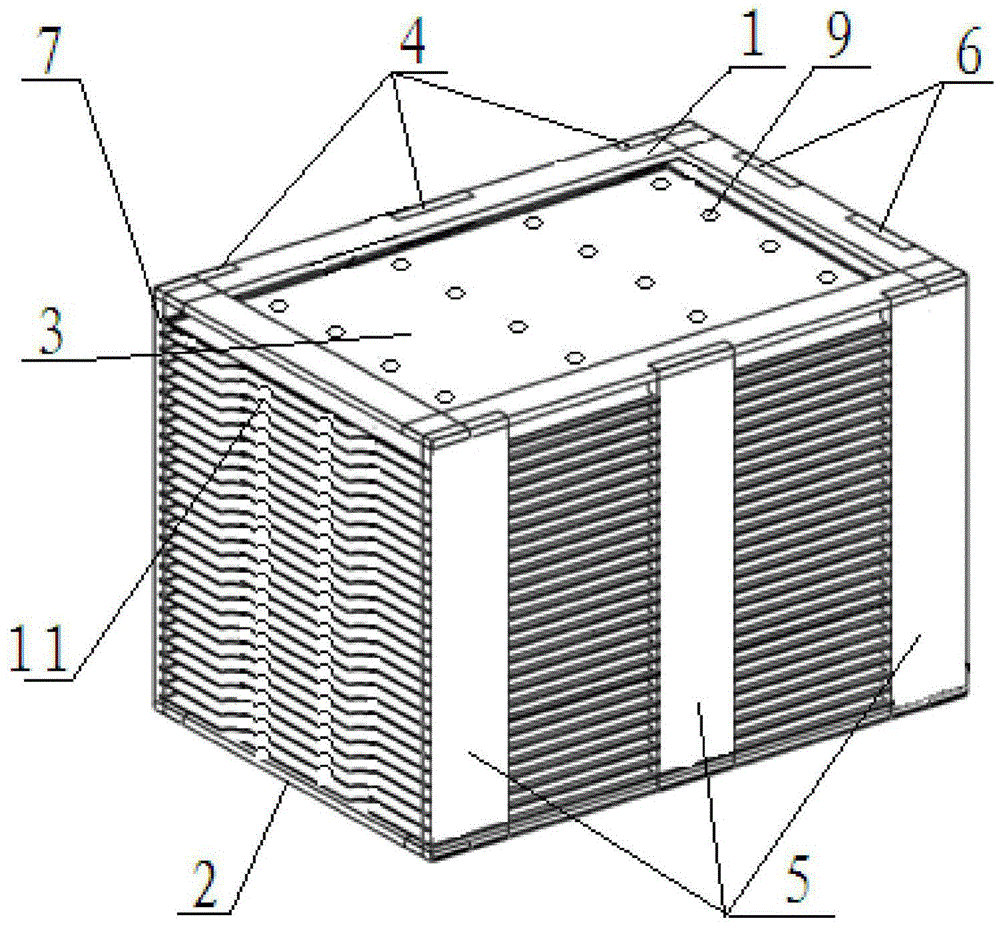

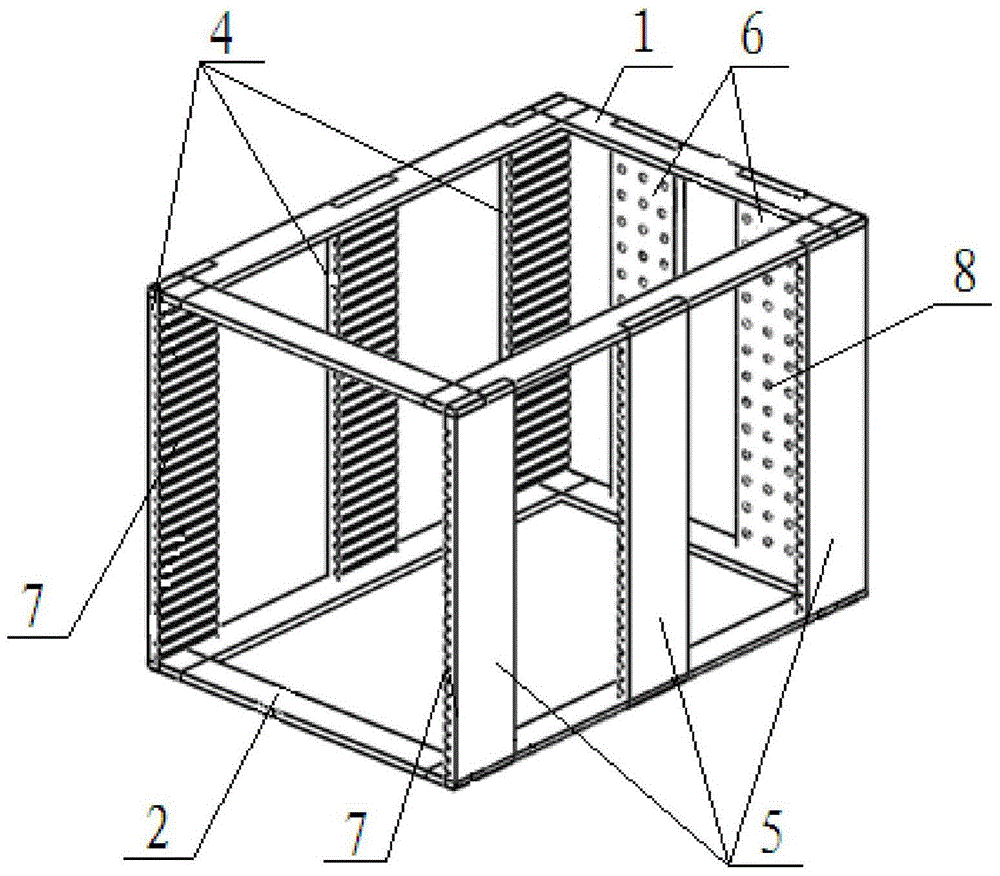

[0044] Include the following steps:

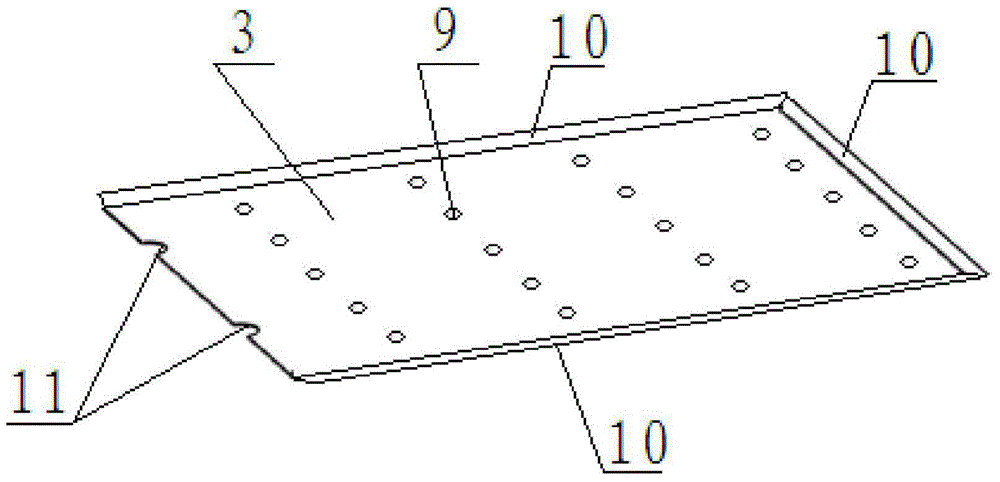

[0045] Step 1, put 45 micron copper foil into the concave part in the middle of the loading tray 3;

[0046] Step 2, inserting a plurality of loading trays 3 loaded with copper foil into the tray groove 7 in parallel;

[0047] Step 3, placing the jig loaded with copper foil in the graphene growth device, and depositing the graphene film by chemical vapor deposition;

[0048] Step 4, after the graphene growth is completed, the fixture is first accurately and quickly taken out from the graphene growth device by the manipulator, and then the manipulator removes the loading tray 3 from the fixture, and then the copper foil grown with graphene Take it off from the loading tray 3 to obtain the copper foil with graphene growing on it, so as to ensure the flatness of the surface of the copper foil during the whole process.

Embodiment 2

[0050] Include the following steps:

[0051] Step 1, put 45 micron nickel foil into the concave part in the middle of the loading tray 3;

[0052] Step 2, inserting a plurality of loading trays 3 loaded with copper foil into the tray groove 7 in parallel;

[0053] Step 3, placing the jig loaded with nickel foil in the graphene growth device, and depositing the graphene film by chemical vapor deposition;

[0054] Step 4, after the graphene growth is completed, the fixture is accurately and quickly taken out from the graphene growth device by the manipulator, and then the manipulator removes the loading tray 3 from the fixture, and then the nickel foil grown with graphene is removed from the manipulator. Take it off from the loading tray 3 to obtain the nickel foil with graphene growing on it, so as to ensure the flatness of the surface of the nickel foil during the whole process.

Embodiment 3

[0056] Include the following steps:

[0057] Step 1, put the 40 micron cobalt foil into the concave part in the middle of the loading tray 3;

[0058] Step 2, inserting a plurality of loading trays 3 loaded with cobalt foils into the tray groove 7 in parallel;

[0059] Step 3, placing the jig loaded with cobalt foil in the graphene growth device, and depositing the graphene film by chemical vapor deposition;

[0060] Step 4, after the graphene growth is completed, the fixture is accurately and quickly taken out from the graphene growth device by the manipulator, and then the manipulator removes the loading tray 3 from the fixture, and then the cobalt foil grown with graphene is removed from the fixture. Take it off from the loading tray 3 to obtain a cobalt foil with graphene growing on it, so as to ensure the smoothness of the surface of the cobalt foil during the whole process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com