Ten-station flour packing machine

A packaging machine and ten-station technology, applied in the field of ten-station flour packaging machines, can solve the problems of troublesome, manual adjustment, low work efficiency, etc., and achieve the effect of simple control mode, high movement accuracy and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

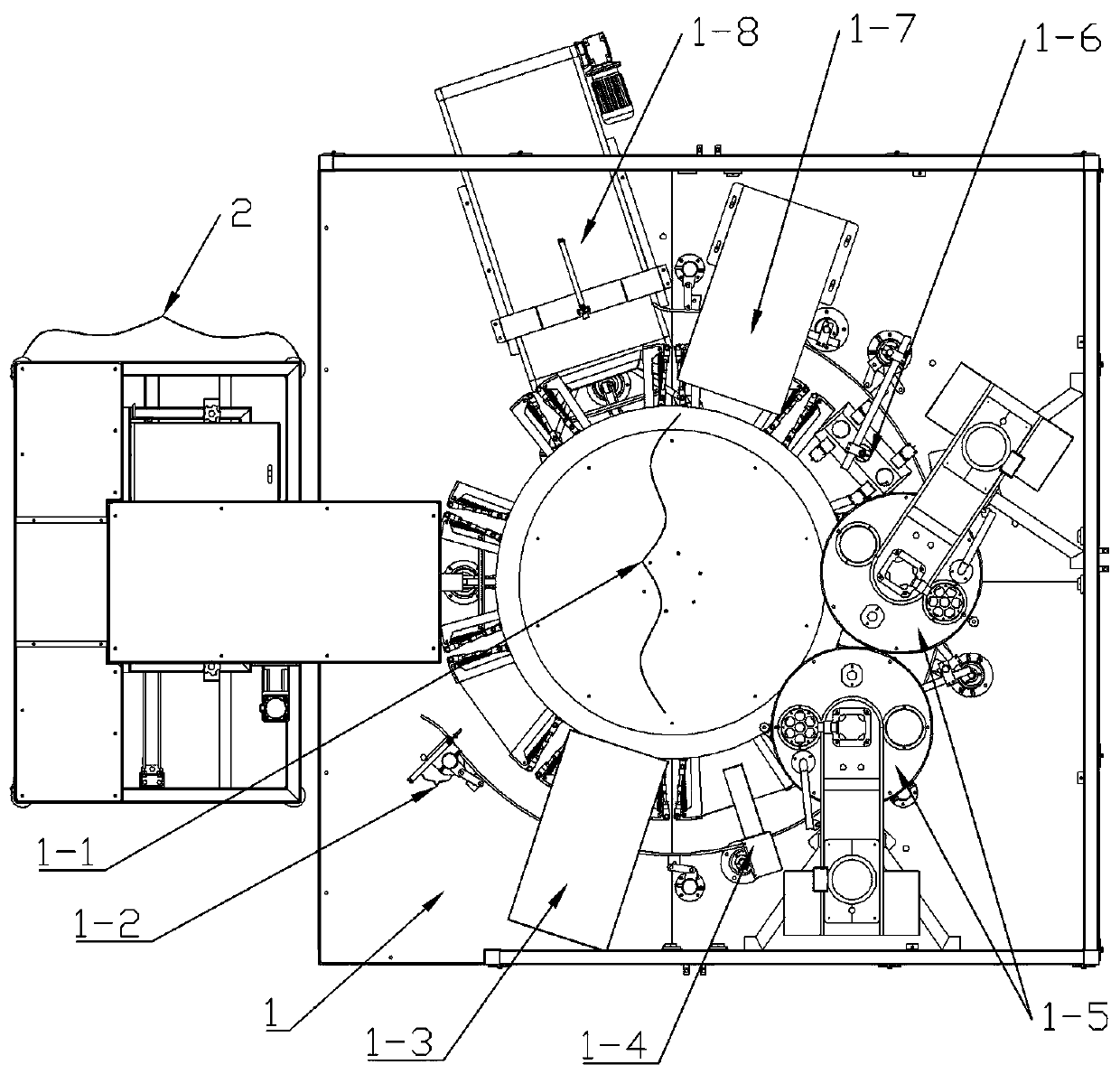

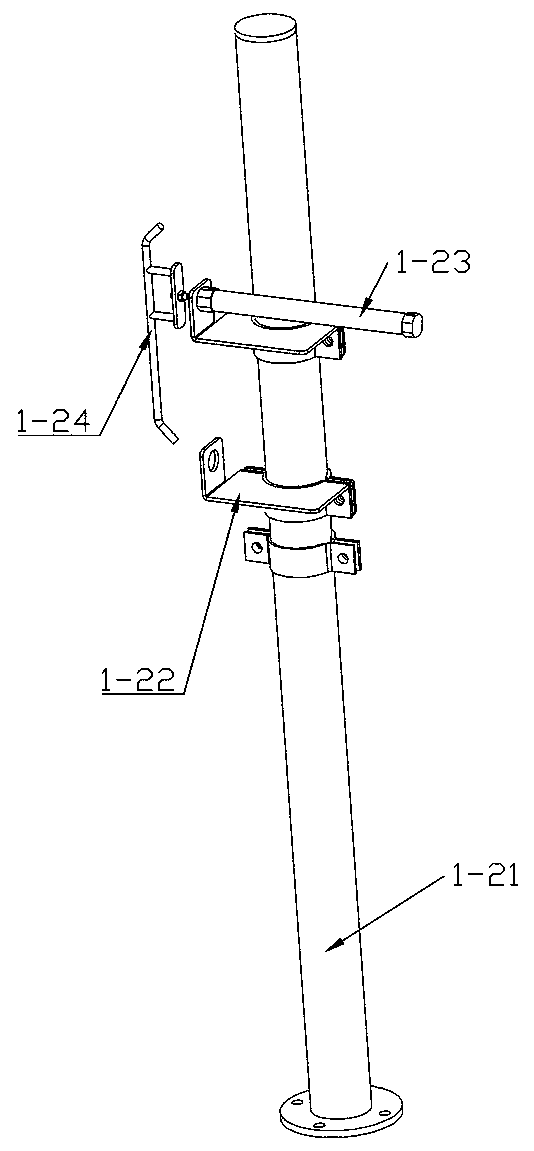

[0064] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention, wherein the filling machines 1-5, dust collectors 1-6, and sealing machines 1-7 are mentioned. , driving motor 2-6, driving element, reducer, acupuncture suction cup 13, and bag taking assembly 2-22 are all existing equipment, wherein the solid acupuncture suction cup 13 and bag taking assembly 2-22 adopt the invention whose application number is 201620174609.5 The single bag taking mechanism of the automatic bag filling machine in the patent will not be described here.

[0065] The specific embodiment of the present invention sees Figure 1-33 :

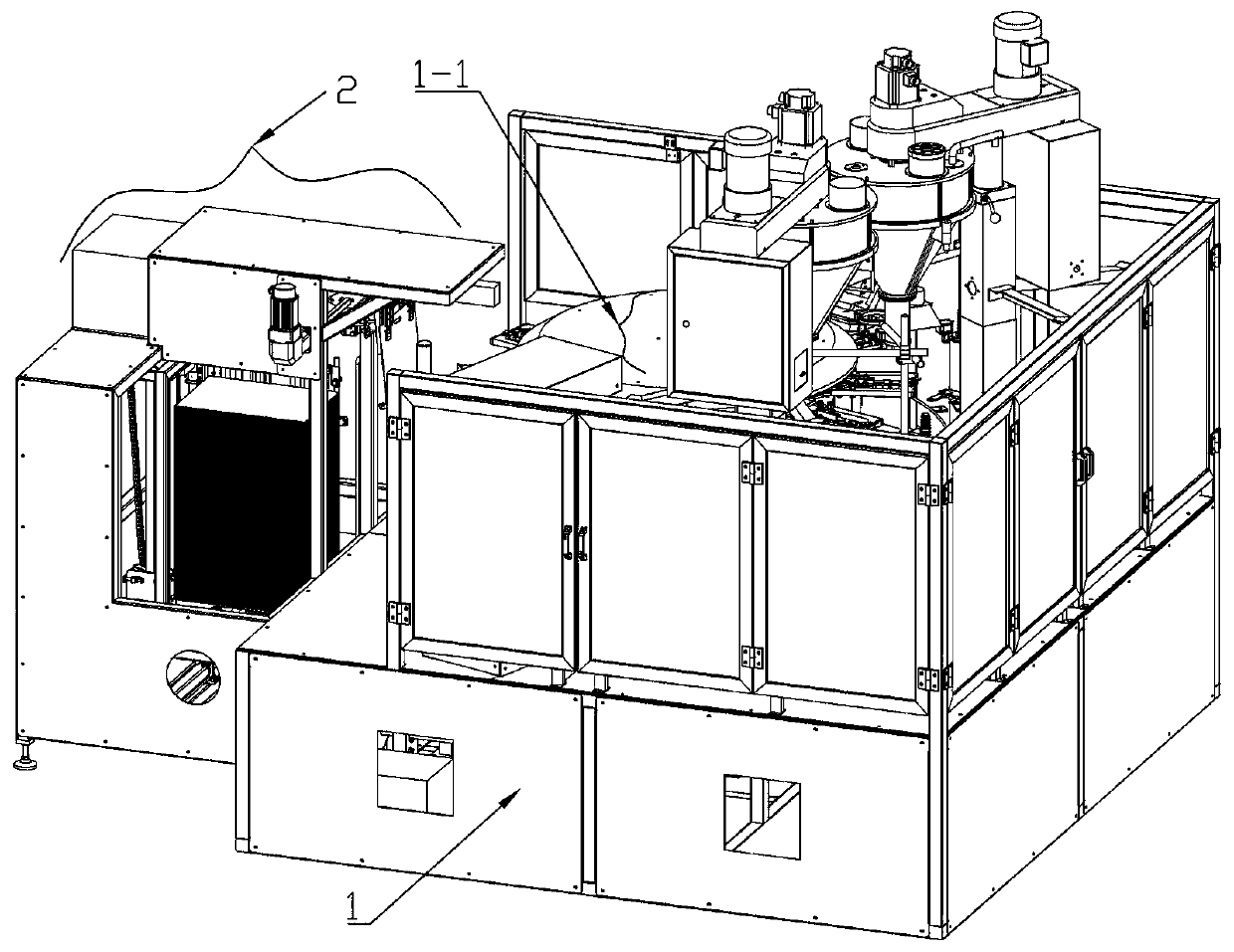

[0066] A ten-station flour packaging machine, such as Figure 1-10 , including working platform 1, bag feeding mechanism 2, packaging bag 6 detection mechanism 1-2, bag opening mechanism 1-3, opening detection mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com