Ultra-miniature stud welding machine

A stud welding machine and ultra-miniature technology, applied in the characteristics of welding rods, welding equipment, welding accessories, etc., can solve the problems of difficult to make small and light in size and weight, waste of energy consumption, heavy machine, etc. The effect of lower price and lower power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

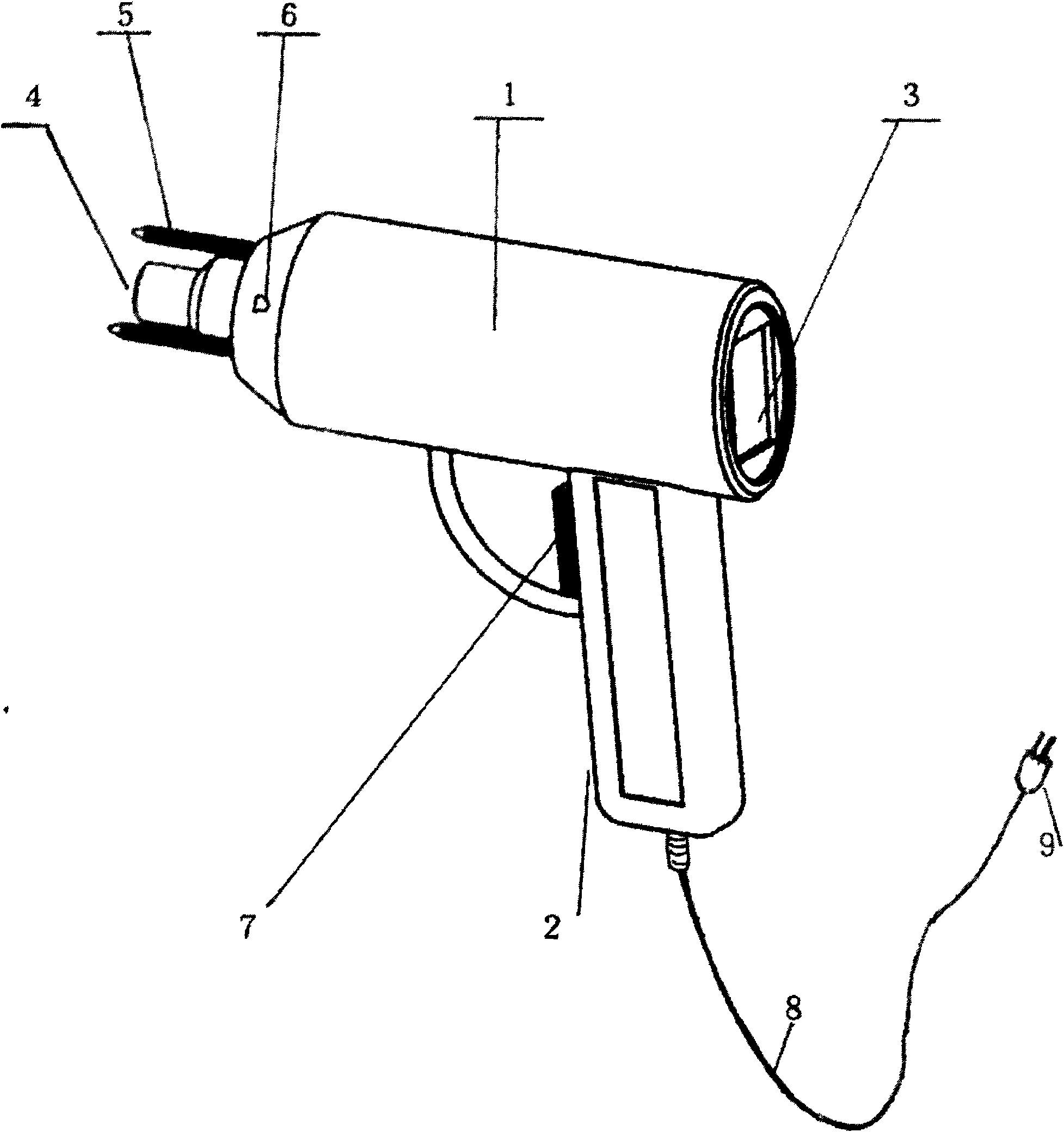

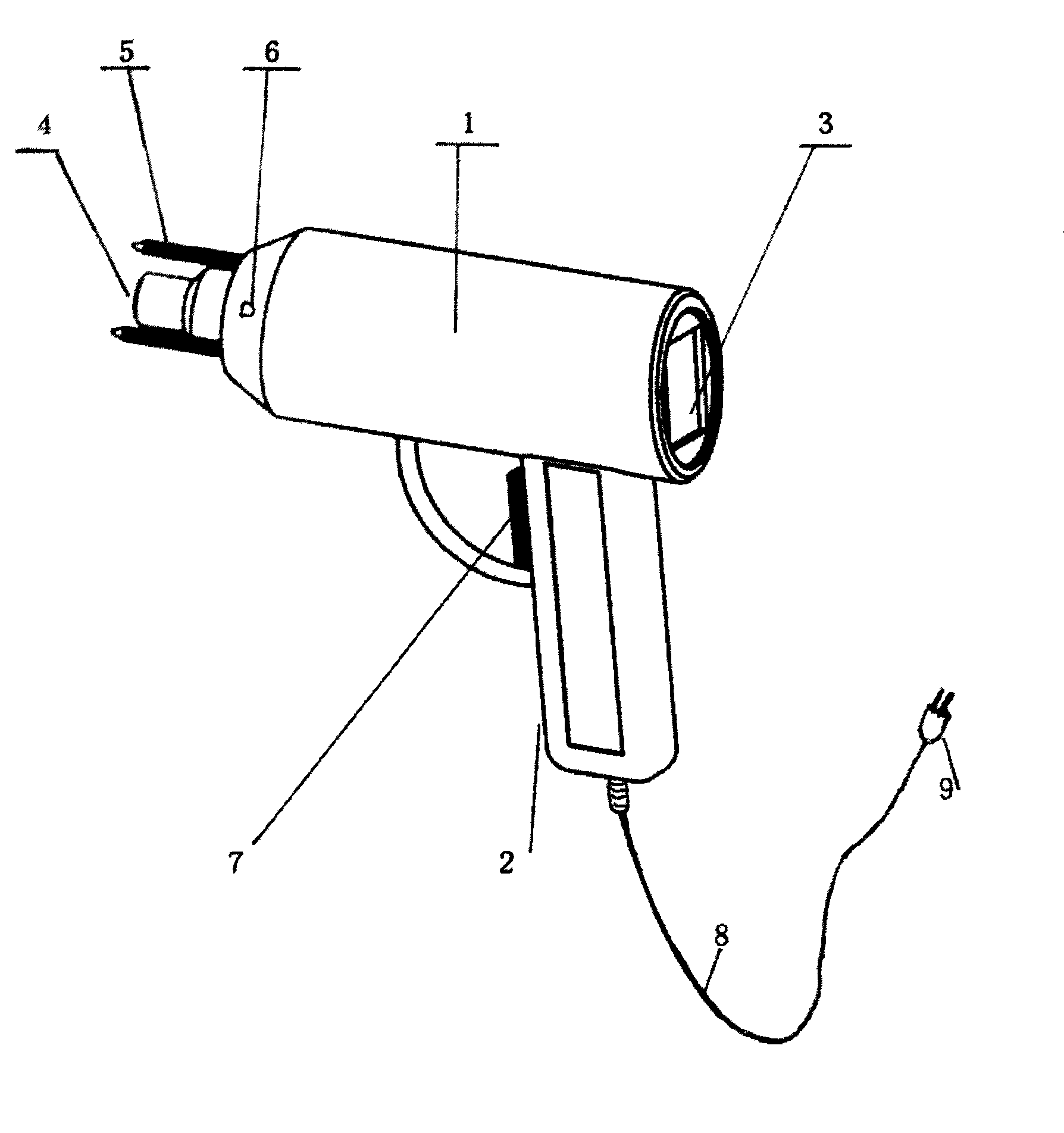

[0013] Refer to the figure: there are thousands of miniature ceramic capacitors placed in the barrel 1 of the stud welding gun, and the energy storage main discharge capacitor of the ultra-miniature stud welding machine is made of a combination of these ceramic capacitors.

[0014] These capacitors are pre-installed on a porous PCB board and then laminated or placed on a polyimide copper film to form a cylindrical or laminated connection and fixation, which can become a columnar ultra-small non-polar super ceramic. capacitance,

[0015] A PWM charging controller and a large current control switch are installed in the welding torch handle 2,

[0016] There is a display window 3 on the hand-held side of the welding torch, and a digital welding energy display and a regulator are installed inside it, and the user sets the welding parameters through this window.

[0017] There is a stud clamping head 4 at the front end of the welding torch, and the stud clamping head on the weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com