Full-automatic stud welding equipment

A welding equipment and fully automatic technology, applied in welding equipment, arc welding equipment, welding accessories, etc., can solve the problems of manual operation, low production efficiency, time-consuming and laborious, etc., and achieve the effect of improving precision and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

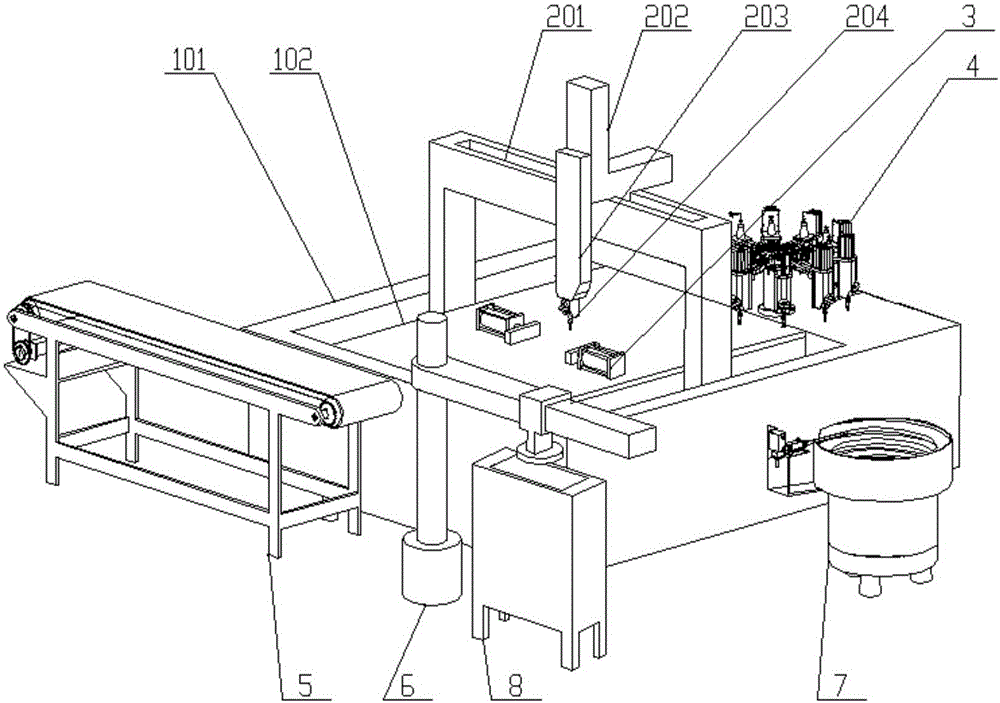

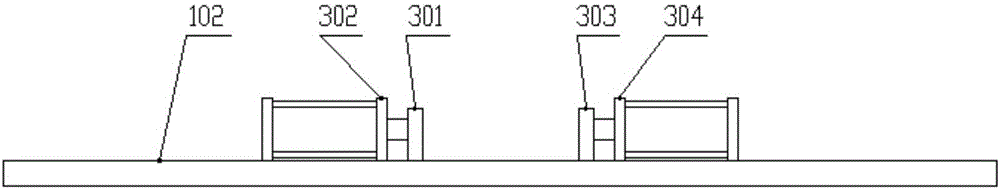

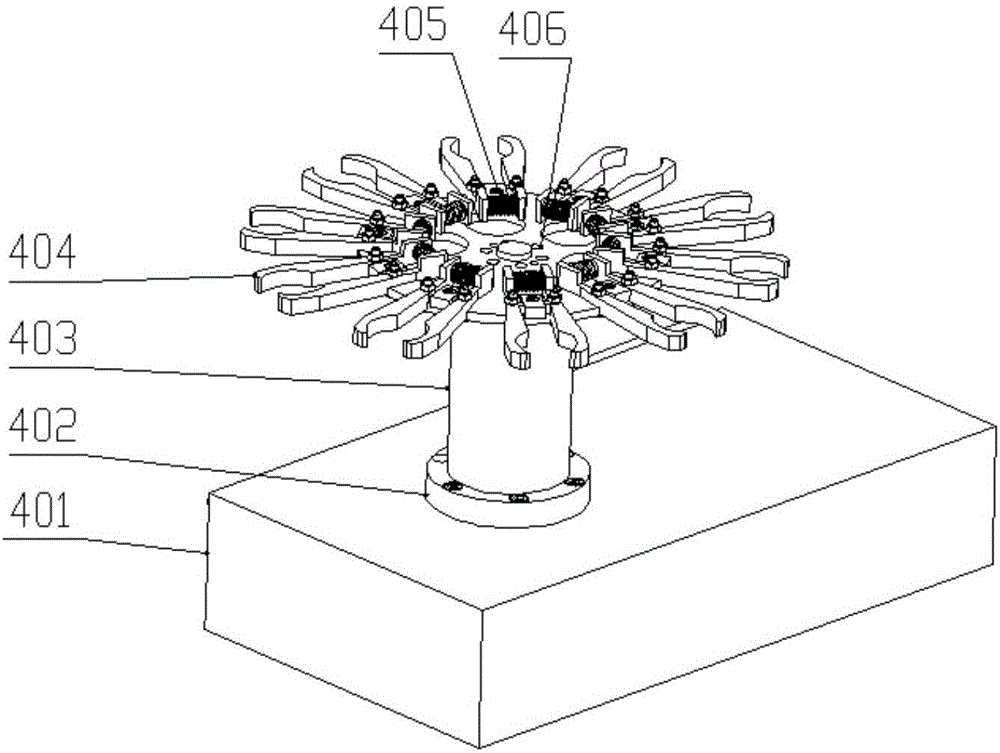

[0032] control figure 1 , the full-automatic stud welding equipment is composed of a welding platform, a welding mechanism, a workpiece fixture mechanism 3, a welding torch storehouse mechanism 4, a conveyor belt mechanism 5, a workpiece manipulator mechanism 6, a stud sending mechanism 7 and a workpiece box 8 to be welded . The welding mechanism is arranged on the welding platform, the workpiece clamp mechanism 3 is arranged on the welding platform, the welding torch magazine mechanism 4 is arranged on the welding platform, the conveyor belt mechanism 5 is arranged in front of the welding platform 1, and the workpiece manipulator mechanism 6 is arranged in front of the conveyor belt mechanism 5.

[0033] control figure 1 , the welding platform includes a bottom frame 101 and a bottom plate 102, and the bottom plate 102 is arranged on the bottom frame 101.

[0034] control figure 1 , the welding mechanism comprises a longitudinally moving crossbeam 201, a laterally moving s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com