Stud welding robot for automobile welding line

A welding production line and welding robot technology, applied in the field of robots, can solve the problems of affecting the welding speed of the production line, high input cost, time-consuming and laborious, etc., and achieve the effect of reducing the number of equipment, reducing investment, and improving welding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

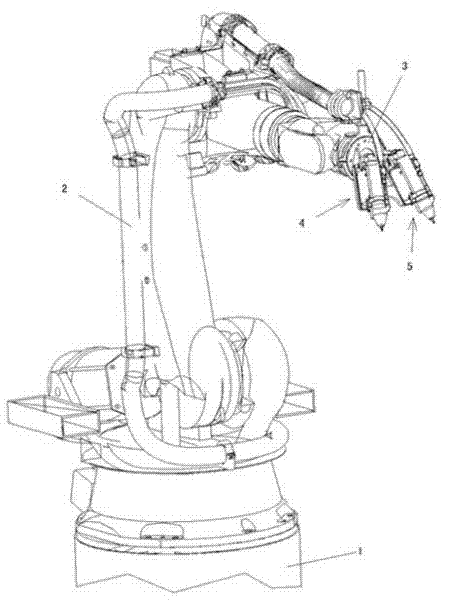

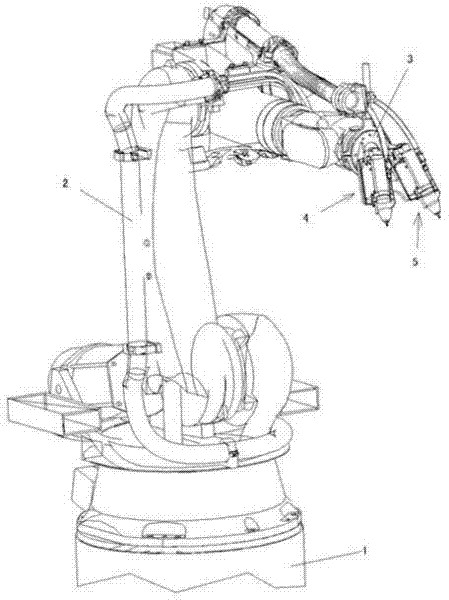

[0007] Such as figure 1 As shown: 1 is the base, the robot body 2 is installed on the base 1, and the top of the robot body 2 includes six axes. The first stud welding torch 4 and the second stud welding torch 5 of different specifications are fixedly connected with the bolts to form a double stud welding torch structure. When welding, it is determined to use a certain stud welding torch according to the needs. If the welding specifications are changed, the stud welding torch can be converted by itself without manual disassembly and replacement, which improves work efficiency and reduces the number of robots equipped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com