Automatic welding gun for realizing arc stud welding of T-shaped welding stud

A technology of automatic welding and stud welding, which is applied in the direction of arc welding equipment, electrode characteristics, welding equipment, etc., can solve problems such as unsuitable use requirements, reduced welding efficiency, and shortened welding arc ignition distance, so as to meet the requirements of use and The effect of maintenance, avoiding short service life and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

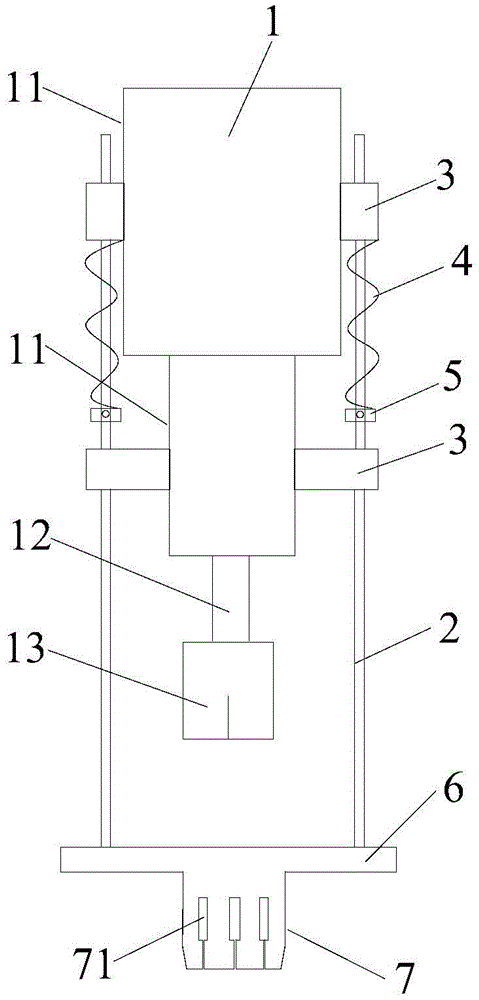

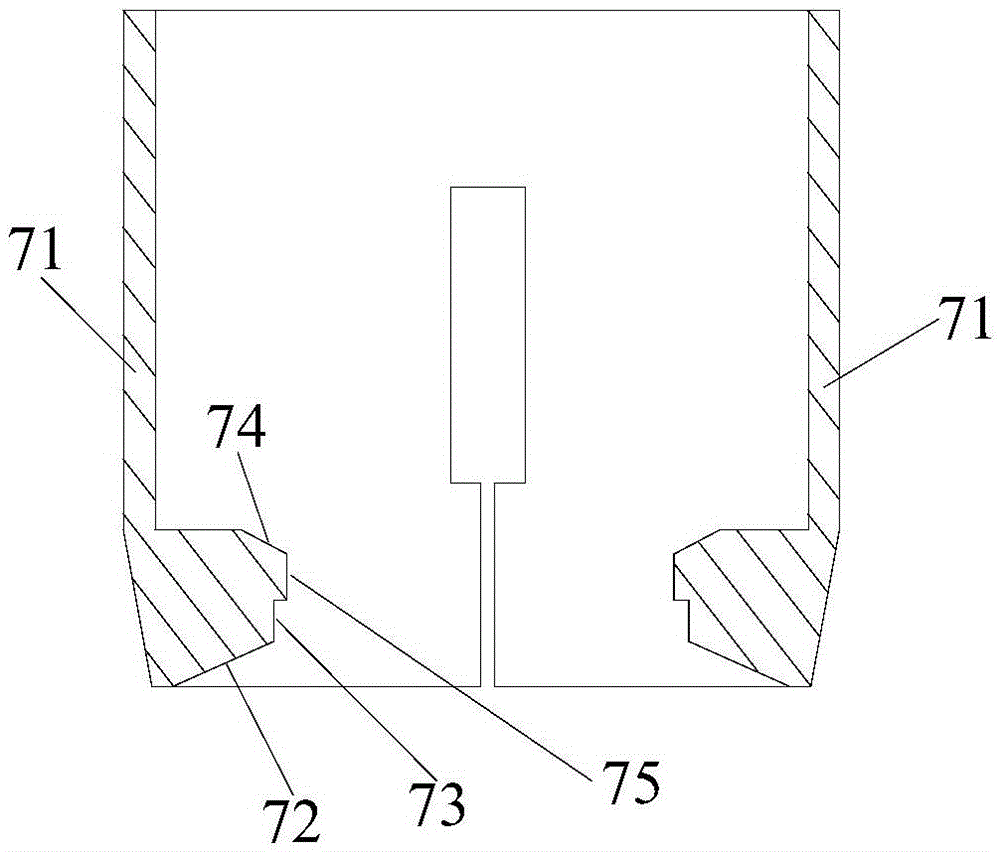

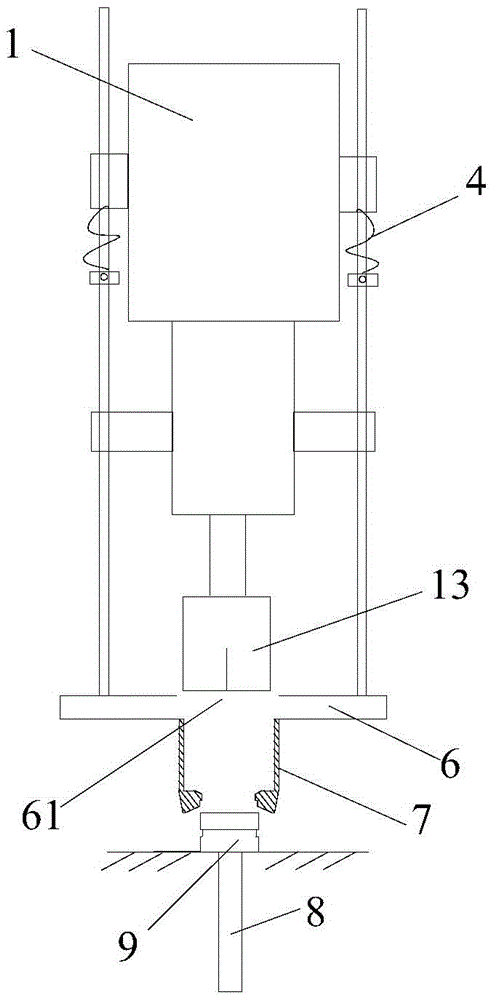

[0028] Such as figure 1 Shown: this embodiment provides an automatic welding gun for realizing arc stud welding of T-shaped welding nails, including a welding torch main body 1, the welding torch main body 1 including a housing 11, a main shaft 12 and a utility model arranged at the front end of the main shaft 12 To install the welding nail chuck 13; on both sides of the housing 11 is provided with guide posts 2, on each side of the housing 11 is provided with a guide sleeve 3, each side of the guide post 2 It is located in the upper and lower guide sleeves 3 on the same side, and a spring 4 is sleeved on the guide post 2 between the upper and lower guide sleeves 3, and a limit block 5 is provided at the lower end of the spring 4 (adjustable Nuts, convenient for adjustment and operation), a fixing seat 6 is fixedly connected to the lower ends of the guide posts 2 on both sides, and a perforation is provided on the fixing seat 6 and directly under the welding nail chuck 13 for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com