Device for realizing full-automatic stud welding of T-type welding stud

An automatic welding and fully automatic technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problem of automatic socket connection between T-shaped welding studs and porcelain rings, no T-shaped welding stud conveying technology, and hidden safety hazards for operators. and other problems, to achieve obvious industrial application value, improve welding efficiency and quality, and stabilize welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

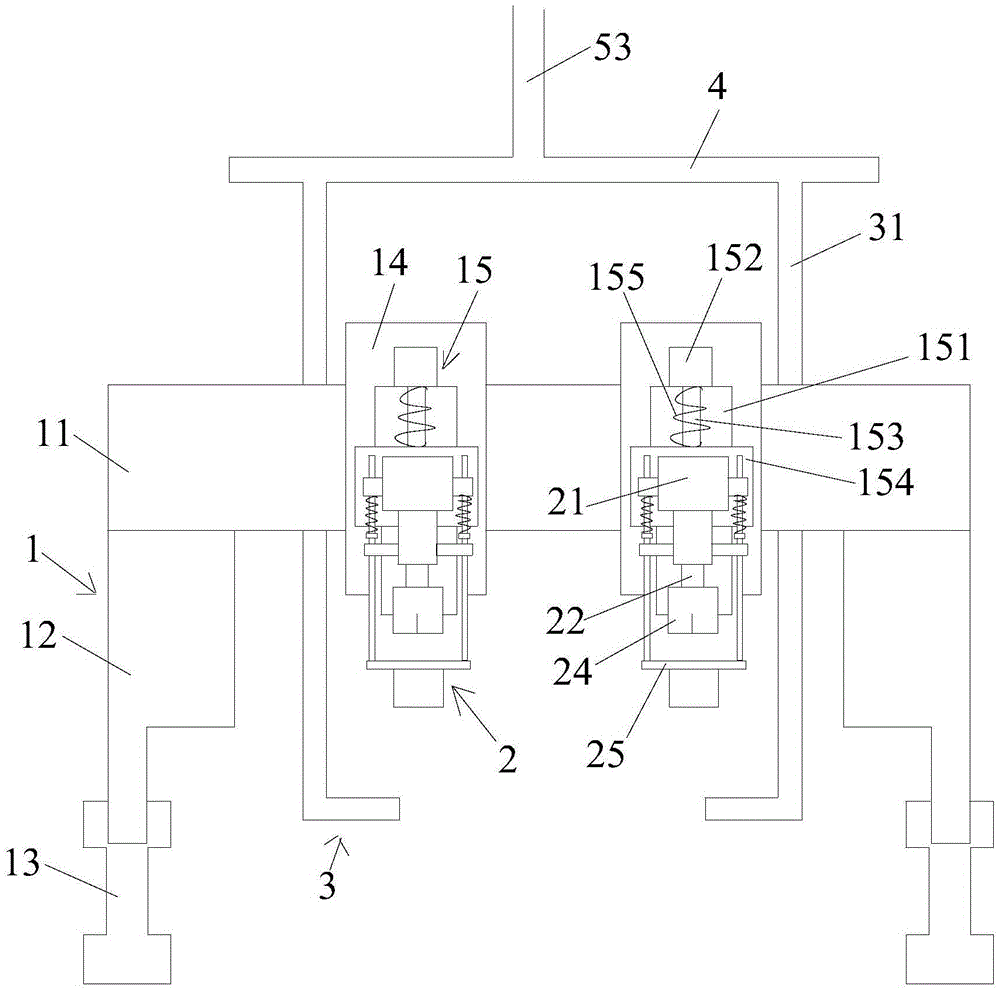

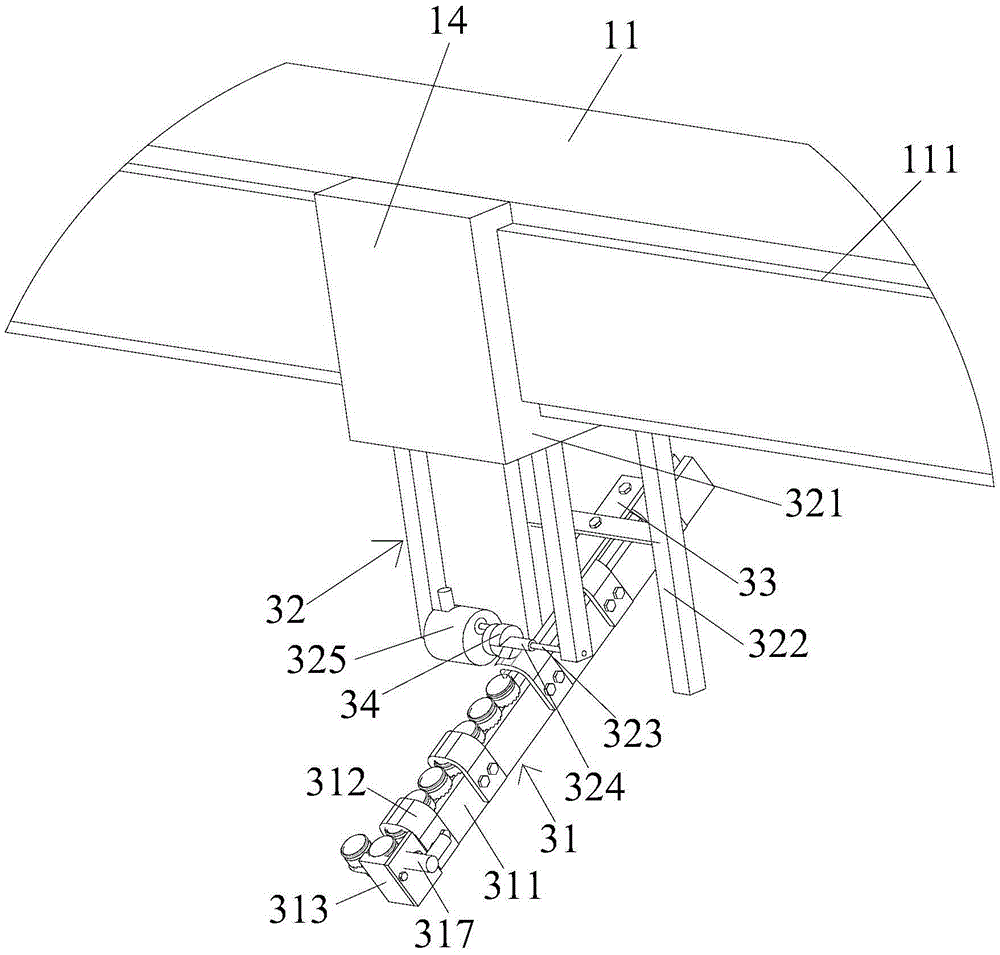

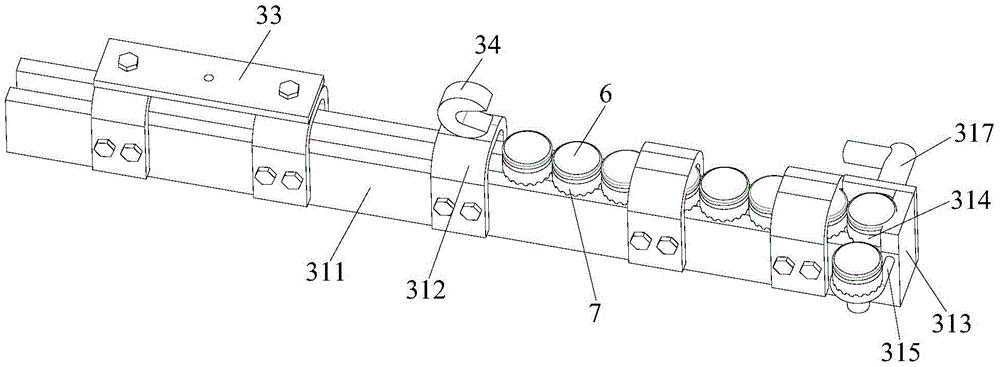

[0050] like figure 1 Shown: a device provided by the present invention for fully automatic stud welding of T-shaped welding studs, including a three-axis motion platform 1, several automatic welding guns 2, several automatic feeding mechanisms 3, and T-shaped welding studs with ceramic rings The conveying track 4 and the automatic socket mechanism of the T-shaped welding stud and the ceramic ring; the automatic welding gun 2 is arranged on the three-axis motion platform 1, and the up-down, left-right and front-back movement of the automatic welding gun 2 is realized through the three-axis motion platform 1, To achieve accurate positioning to the spot to be welded; each automatic welding gun 2 is equipped with an automatic feeding mechanism 3, and the automatic feeding mechanism 3 is connected to the three-axis motion platform 1, and can be moved synchronously with the automatic welding gun 2 through the three-axis motion platform 1 position, and the automatic feeding mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com