A device for realizing automatic socketing of T-shaped welding studs and ceramic rings

A technology of welding nails and porcelain rings, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of hindering automatic stud welding of T-shaped welding nails and low welding efficiency, and achieve obvious industrial application value and work efficiency. High, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings.

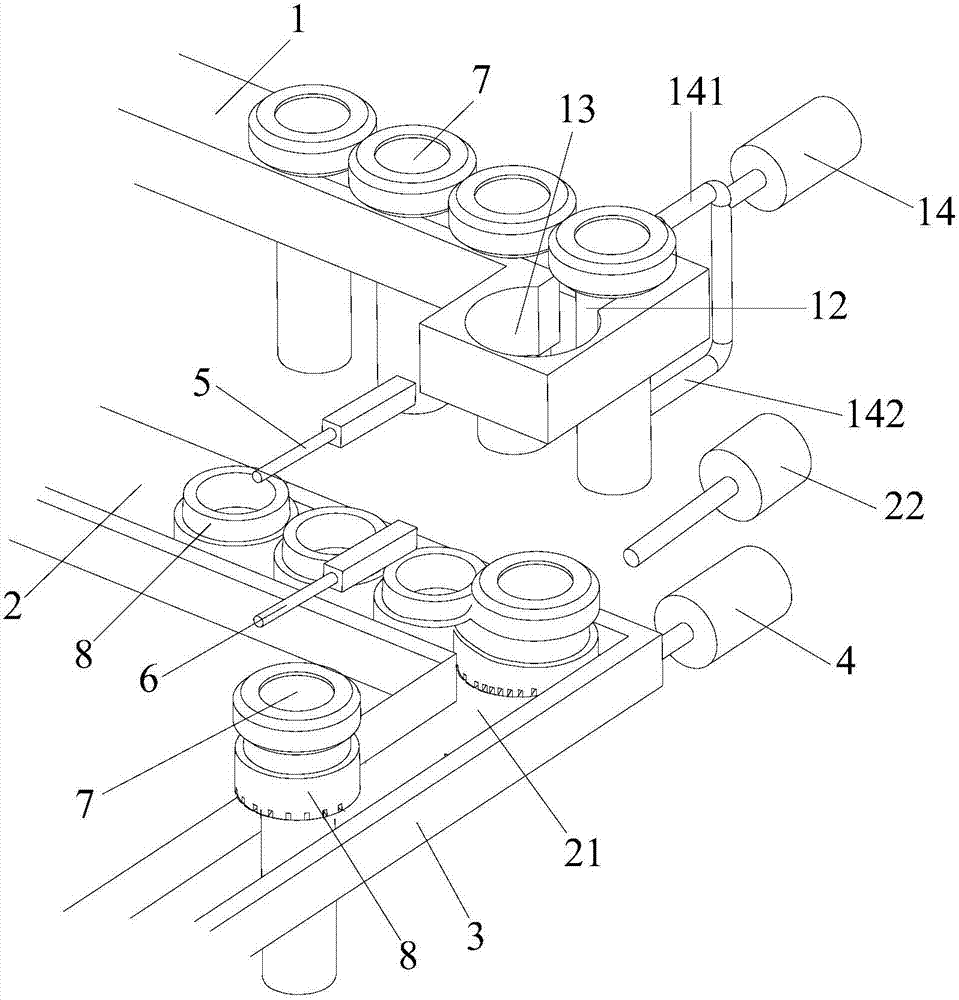

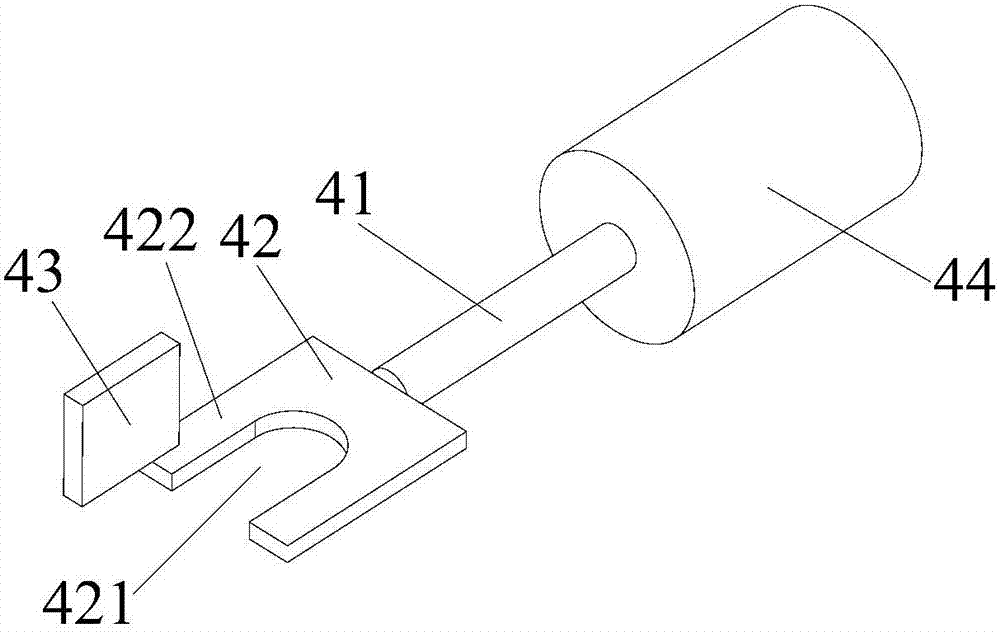

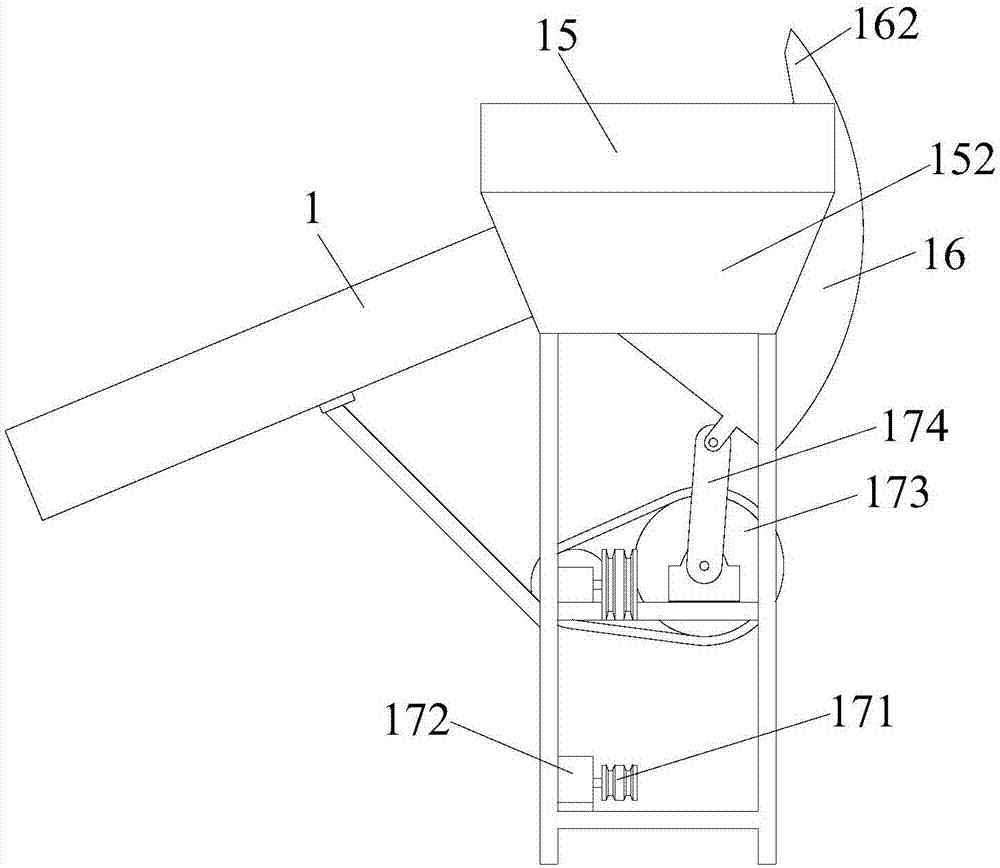

[0029] Such as figure 1 Shown: a device provided by the present invention to realize the automatic socketing of T-shaped welding studs and ceramic rings, including a T-shaped welding stud deriving track 1, a porcelain ring deriving track 2 and an output track 3, where the T-shaped welding studs are derived One side of the end of the track 1 is provided with an opening 12 and a nail drop hole 13 communicating with the opening 12, on the other side of the end of the T-shaped welding nail leading out of the track 1 and opposite to the opening 12 A pushing mechanism A 14 is provided; an outlet 21 is provided on one side of the end of the ceramic ring deriving track 2, and an outlet 21 is provided on the other side of the end of the ceramic ring deriving track 2 and opposite to the outlet 21. Pushing mechanism B22, the outlet 21 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com