High-frequency inversion stud welding equipment and controlling means thereof

A welding equipment and high-frequency inverter technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of reducing the reliability of the whole machine, slow adjustment speed of output current and voltage, and low adjustment frequency, and achieve Improved response speed and control accuracy, improved reliability and stability, and long life of electrical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

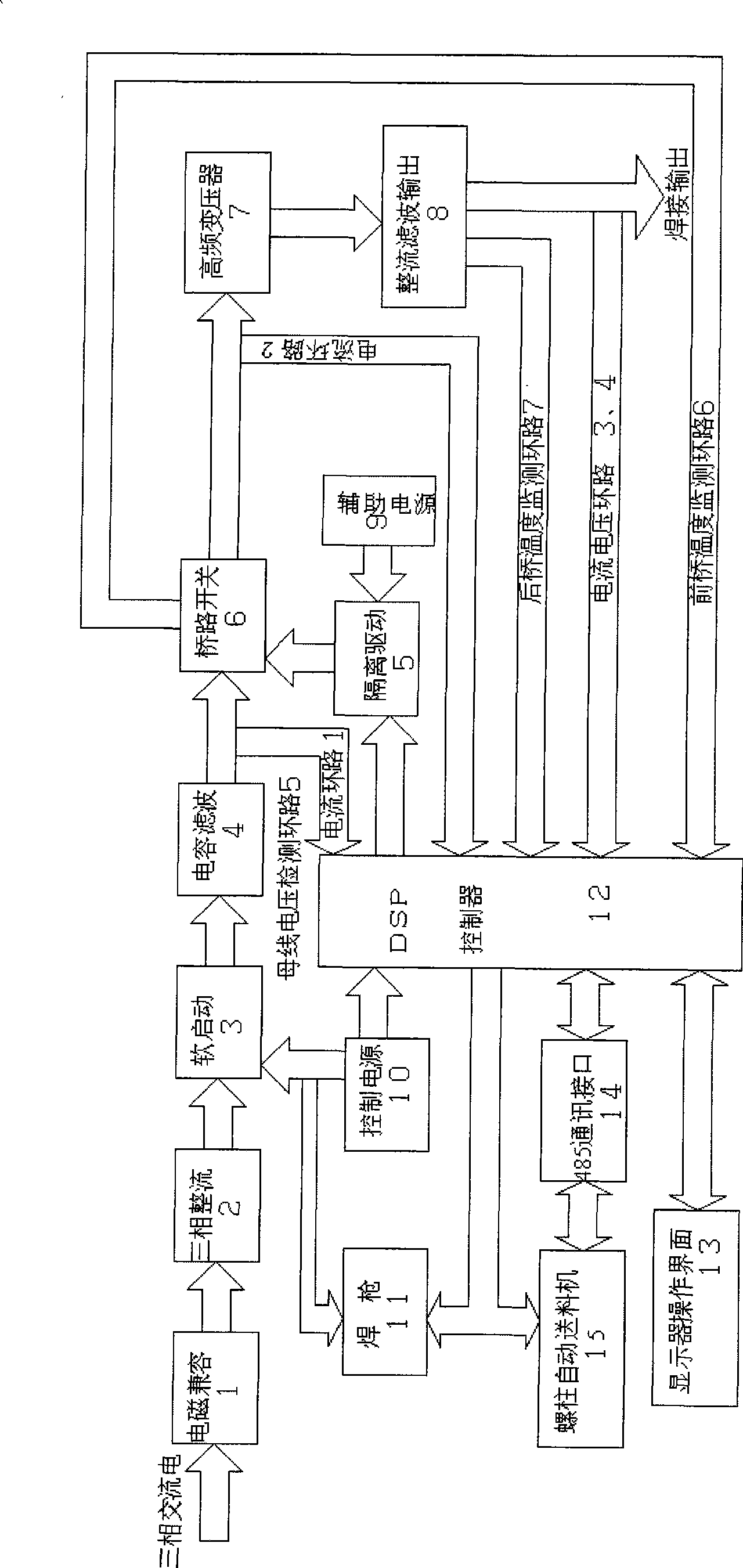

[0040] The composition of the embodiment of the high-frequency inverter stud welding equipment of the present invention is as follows figure 1 shown, including

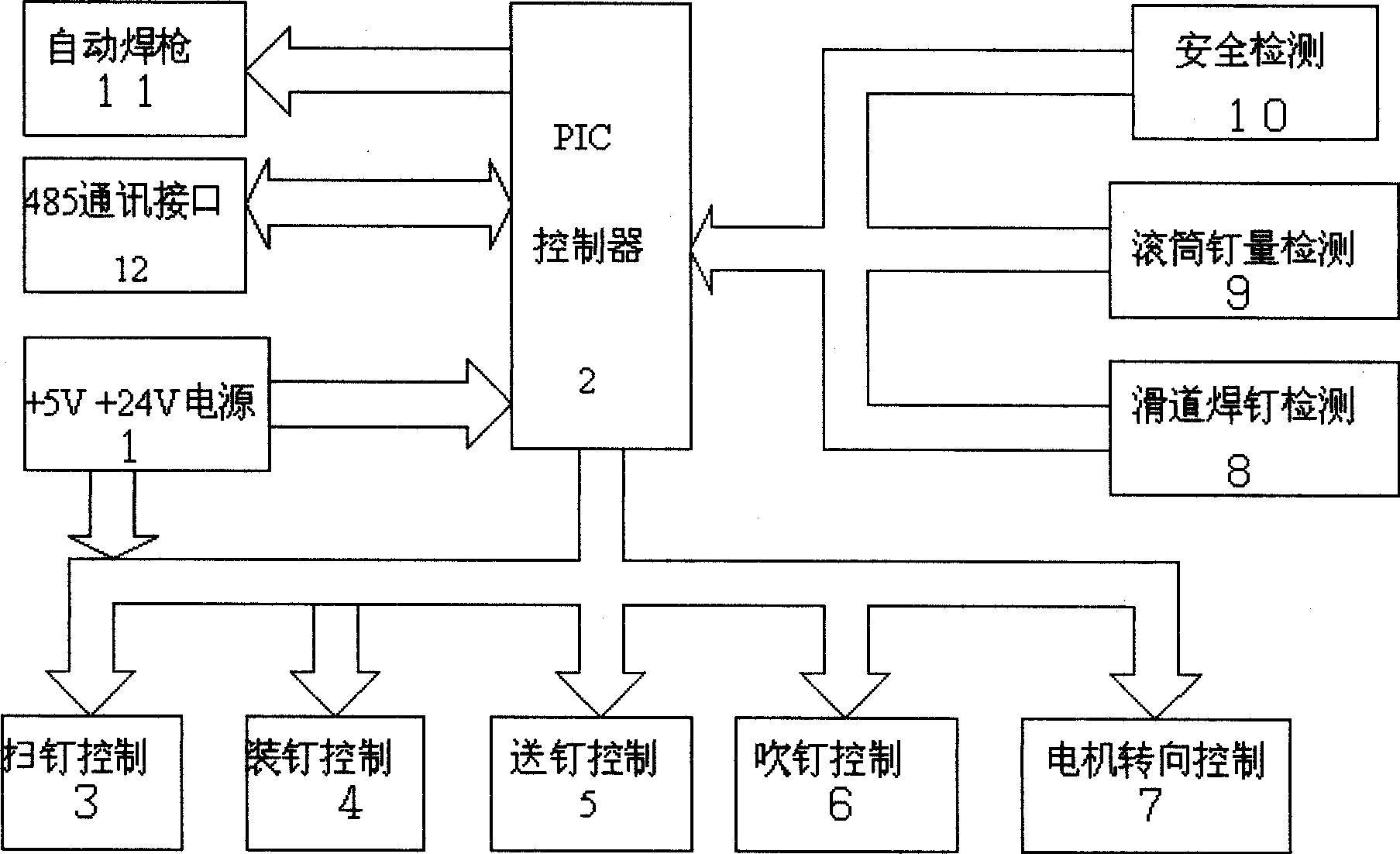

[0041](1) Electromagnetic compatibility circuit, (2) Three-phase AC rectification circuit, (3) Soft start circuit, (4) Rectification filter circuit, (5) IGBT isolation drive circuit, (6) IGBT bridge switch circuit, (7) High-frequency transformer, (8) high-frequency rectification and filtering circuit, (9) IGBT auxiliary power supply, (10) control power supply, (11) welding torch, (12) DSP controller, (13) man-machine interface that is LCD display screen, ( 14) 485 communication interface, (15) Stud automatic feeder.

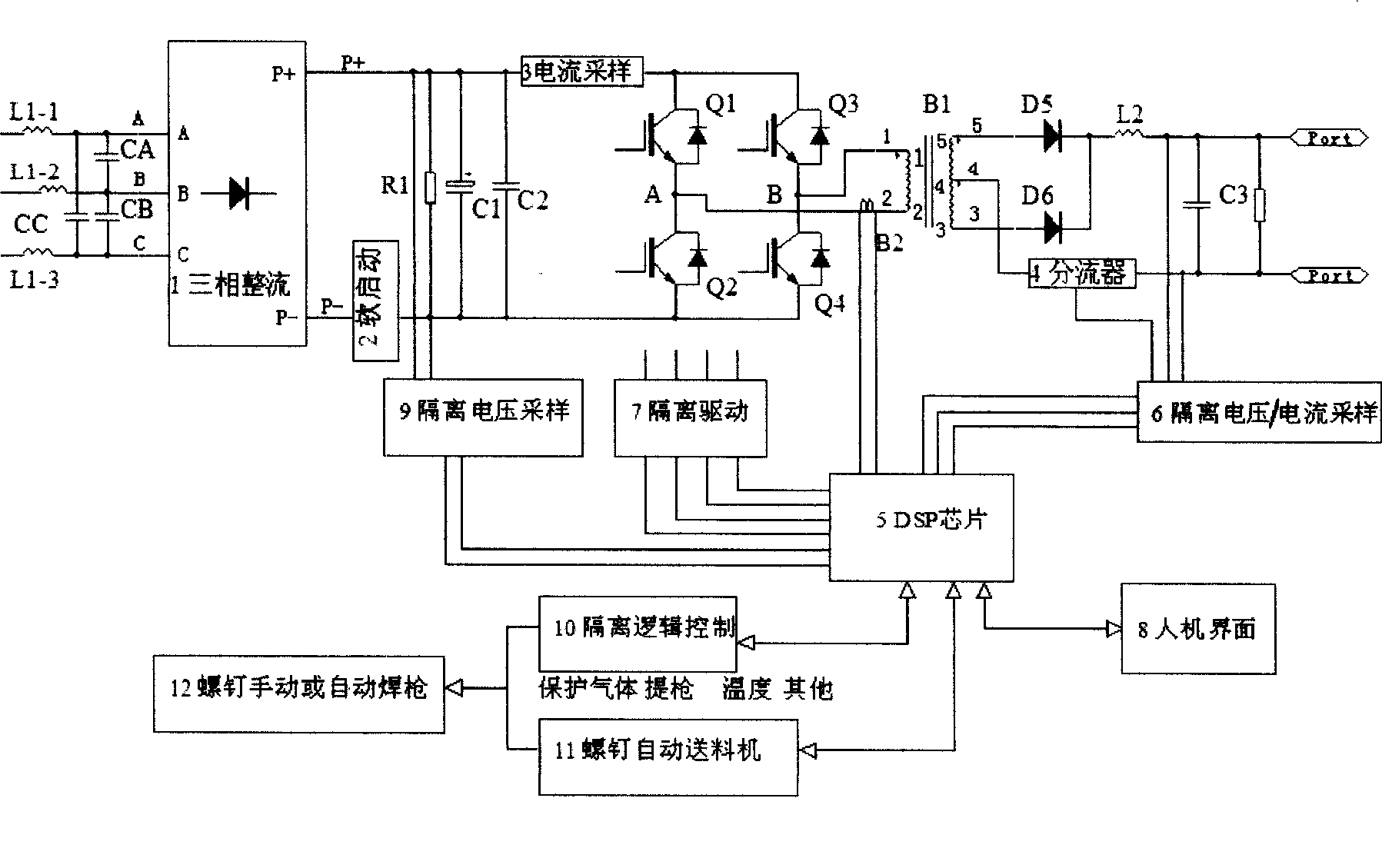

[0042] The working principle of the embodiment of the high-frequency inverter stud welding equipment of the present invention is as follows figure 2 shown. The three-phase AC passes through the electromagnetic compatibility circuit, and uses capacitors CA, CB, CC, and inductors L1-1, L1-2, and L1-3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com