Stepping electric arc stud welding gun

An arc screw and step-by-step technology, which is applied to arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of arc length variation, influence on process, and insufficient stud feeding depth, etc., and achieve the effect of arc length adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

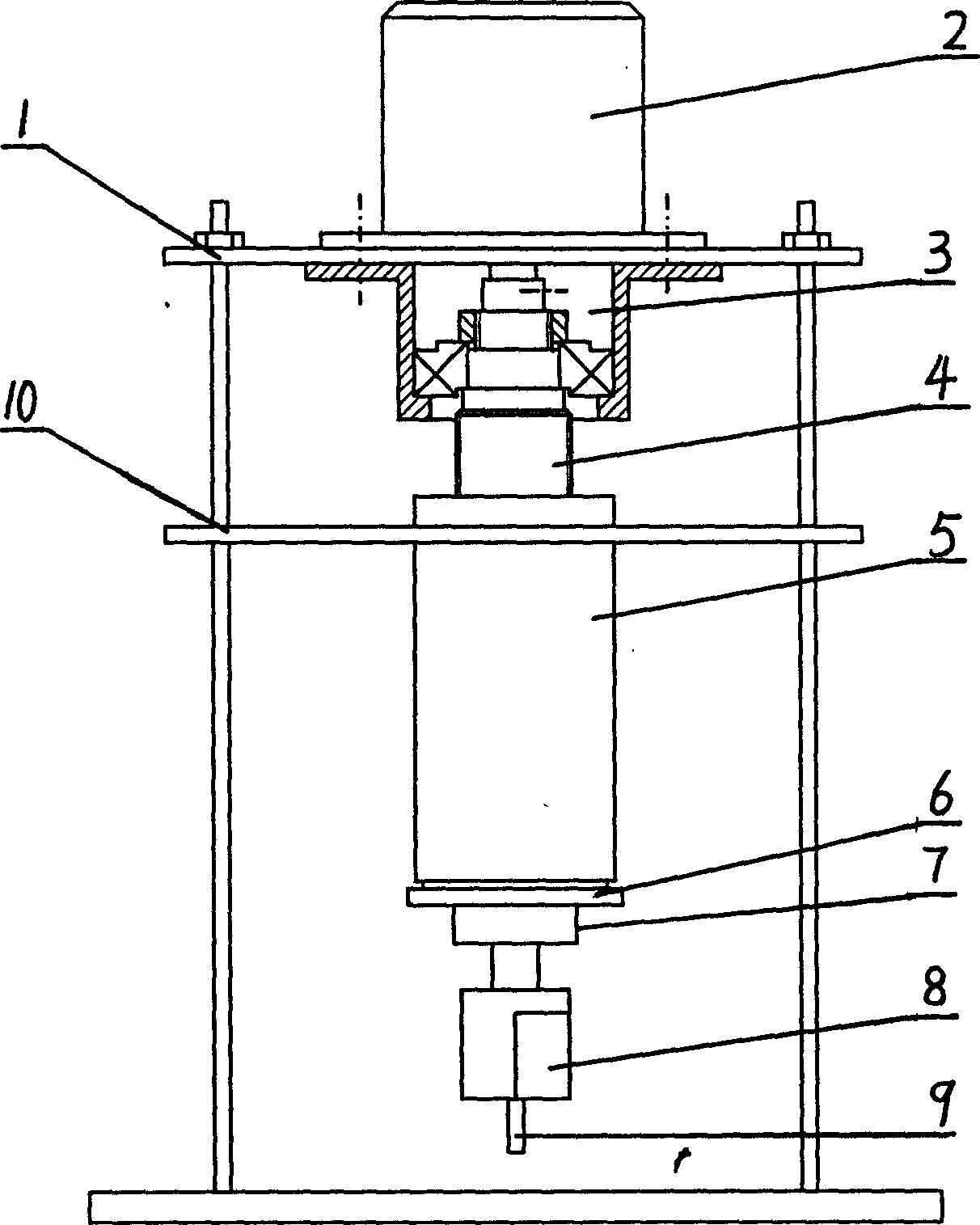

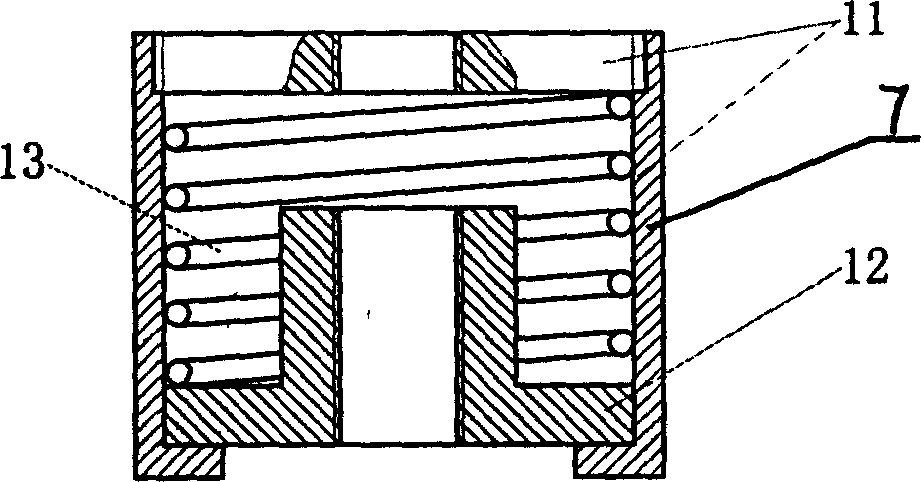

[0010] see figure 1 , the present invention comprises a frame 1 and a stepping motor 2 arranged on the upper end of the frame 1, a lead screw 4 is fixed on the shaft of the stepping motor 2, and a drive nut 5 is screwed on the lead screw 4, and the drive nut 5 is connected with the sleeve The guide plate 10 on the guide rod of the frame 1 is fixed as a whole, and the lower end of the drive nut 5 is also provided with an insulating plate 6 connected with the drive nut 5, an elastic protection device 7 and a clamp for clamping the stud 9 to be welded 8. The lead screw 4 is also covered with a protective device 3 that adopts a tapered roller bearing. Stepping motor 2 is the power part of the present invention, adopts the hybrid stepping motor that model is 57BYGH803 as drive motor, provides the required pulse si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com