Arc stud welding gun and the welding method thereof

A stud welding and stud technology, applied in arc welding equipment, welding equipment, welding rod characteristics, etc., can solve the problems of uncontrollable stud movement and undetectable stud feeding pressure, so as to improve welding quality and excellent welding The effect of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

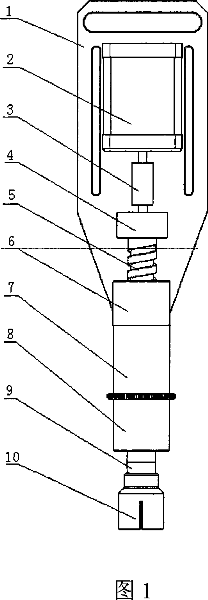

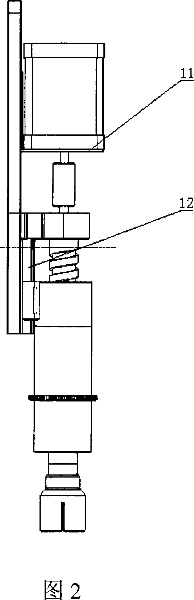

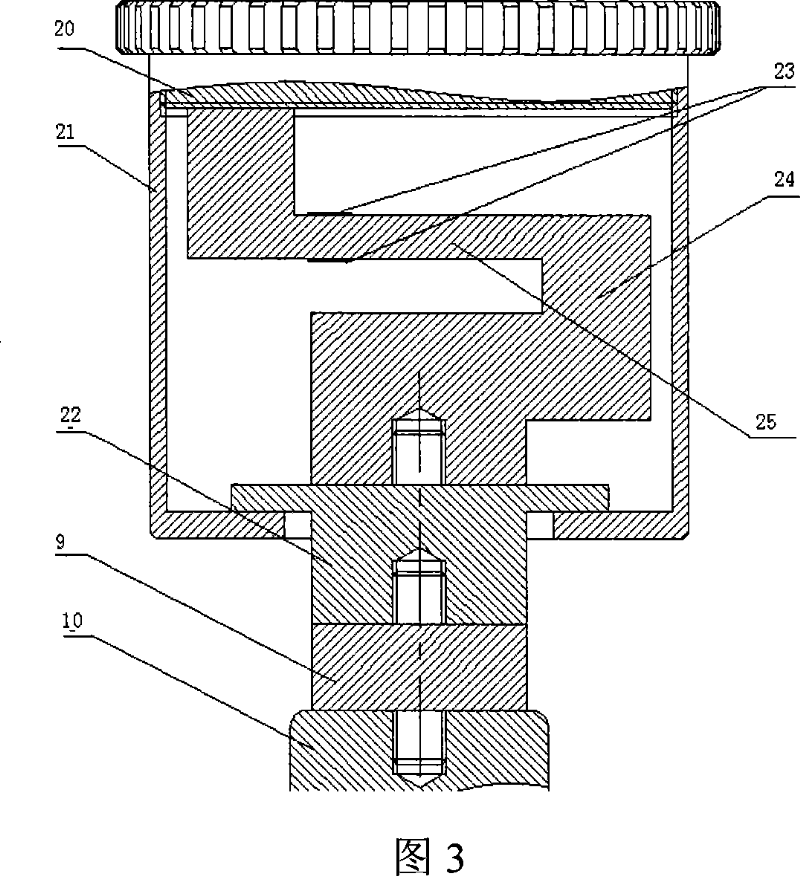

[0019] As shown in Figures 1 and 2, an arc stud welding torch includes a stud clamp 10 (arc welding electrode), a vertical mounting plate 1, and a motor 2 is fixed on one side of the mounting plate 1 by a bracket 11, and the middle part is set The ball screw pair, that is, the bearing 4, the screw 5 and the screw nut 6 matched with its thread, the screw 5 is connected with the rotating shaft of the motor 2 through a coupling 3, and the ball screw pair and the lower part of the mounting plate 1 A linear motion mechanism 12 is provided, and the linear motion mechanism 12 may be a guide rail. The lead screw nut 6 is fixed with a connector 7 and connected with the stud clamp 10 through a pressure sensor 8 , and an insulating block 9 is provided at the connection between the stud clamp 10 and the pressure sensor 8 . The motion of the stud welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com