An assembly device for an insulating pull rod

A technology of insulating pull rods and assembly devices, which is applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of spring elastic operator injury, affecting work efficiency, time-consuming and labor-intensive problems, and achieves simple and easy-to-control movements, reduced labor intensity, and positioning precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

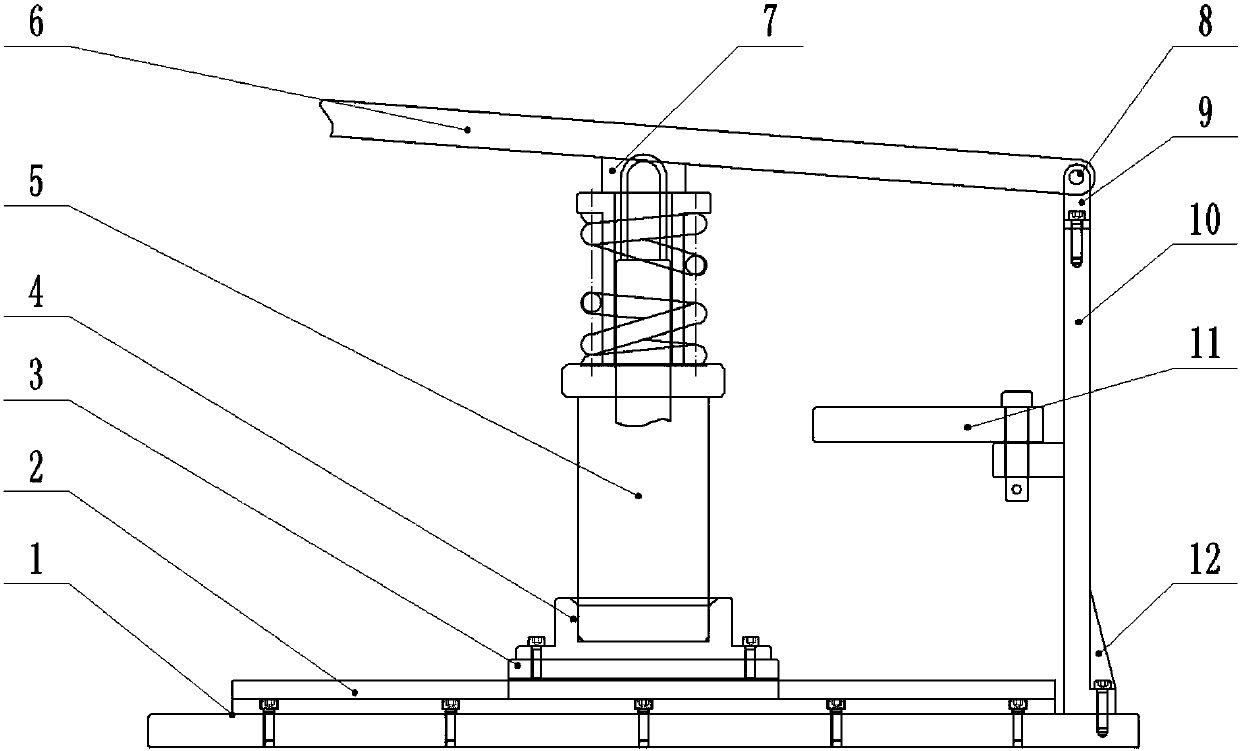

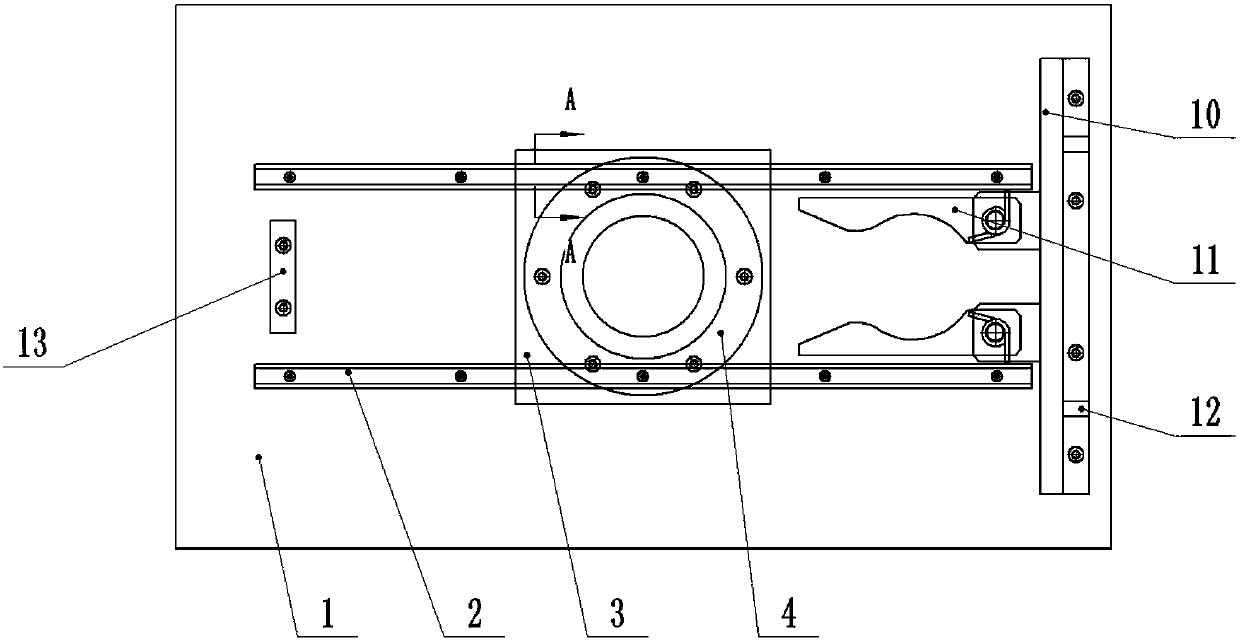

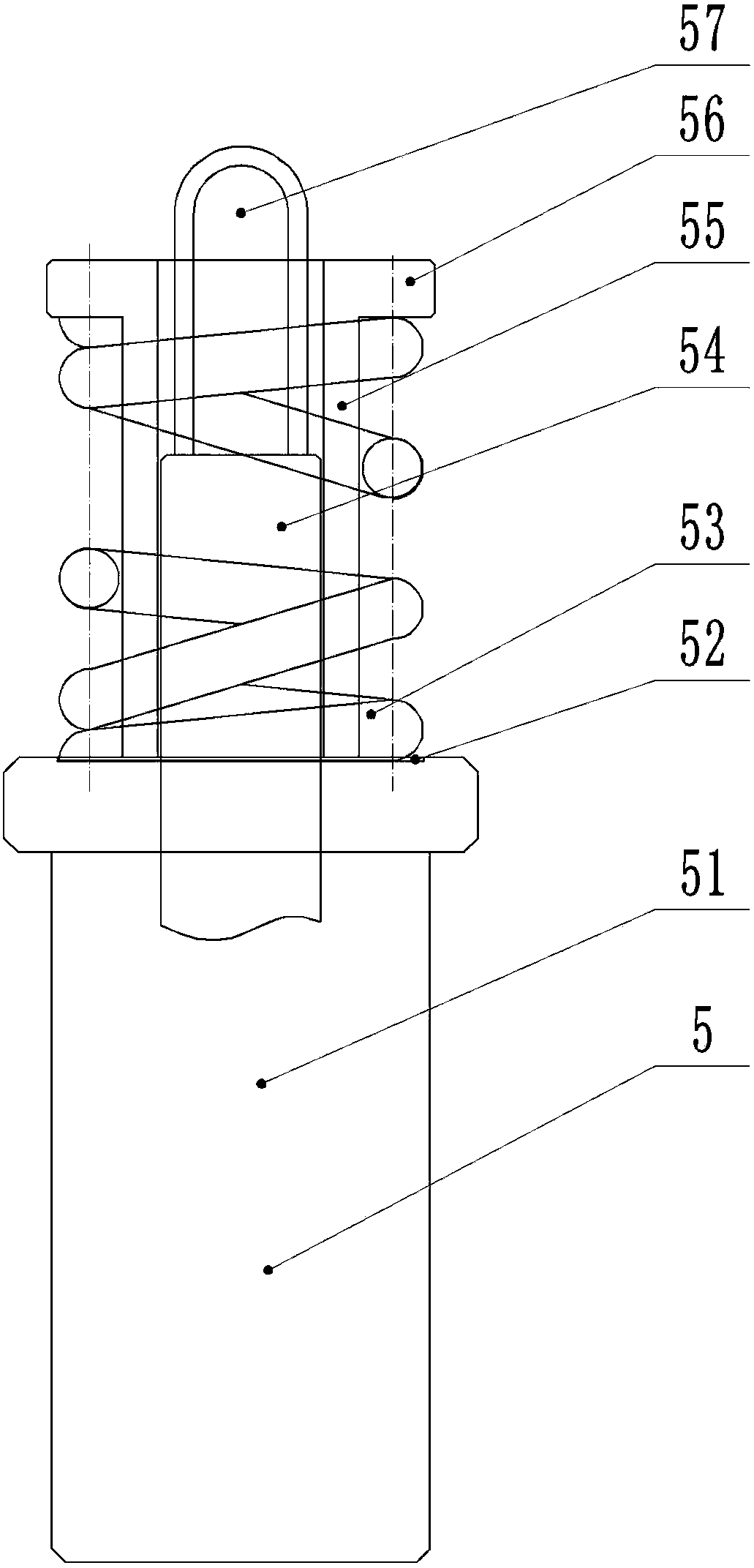

[0033] Such as Figure 1-2 As shown, the assembly device of an insulating tie rod according to the embodiment of the present invention includes: two rails 2 are laid on the workbench 1, a chassis 3 is installed on the track 2, and the insulating tie rod seat 4 is fixed on the chassis 3; the insulating tie rod seat 4 is the round platform of the middle round hole, the body 51 of the insulating pull rod 5 is placed at the round hole, and the middle round hole is chamfered to facilitate the placement of the body 51. The vertical plate 10 is fixedly installed on the right side of the workbench 1 by bolts, and a reinforcing rib 12 is installed on one side of the vertical plate 10 . The left side of workbench 1, the center of track 2 is fixed with bolt and installs stop block 13, and the height of stop block 13 is greater than the height of track 2, and chassis is spaced. The positioning mechanism 11 is installed in the middle of the vertical plate 10. The positioning mechanism 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com