Method for controlling movement of liquid metal by using laser in ionic liquid

A technology of liquid metal and ionic liquid, which is applied in the direction of lasers, phonon exciters, laser components, etc., can solve the problems of controllable motion limitations, limitations, and uncontrollable three-dimensional motion of liquid metals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0040] A method for controlling the movement of a liquid metal with a laser in an ionic liquid, comprising the steps of,

[0041] Step (1): Submerging the liquid metal into a glass container containing an ionic liquid;

[0042] Step (2): irradiating the liquid metal immersed in the ionic liquid through the glass container with a laser;

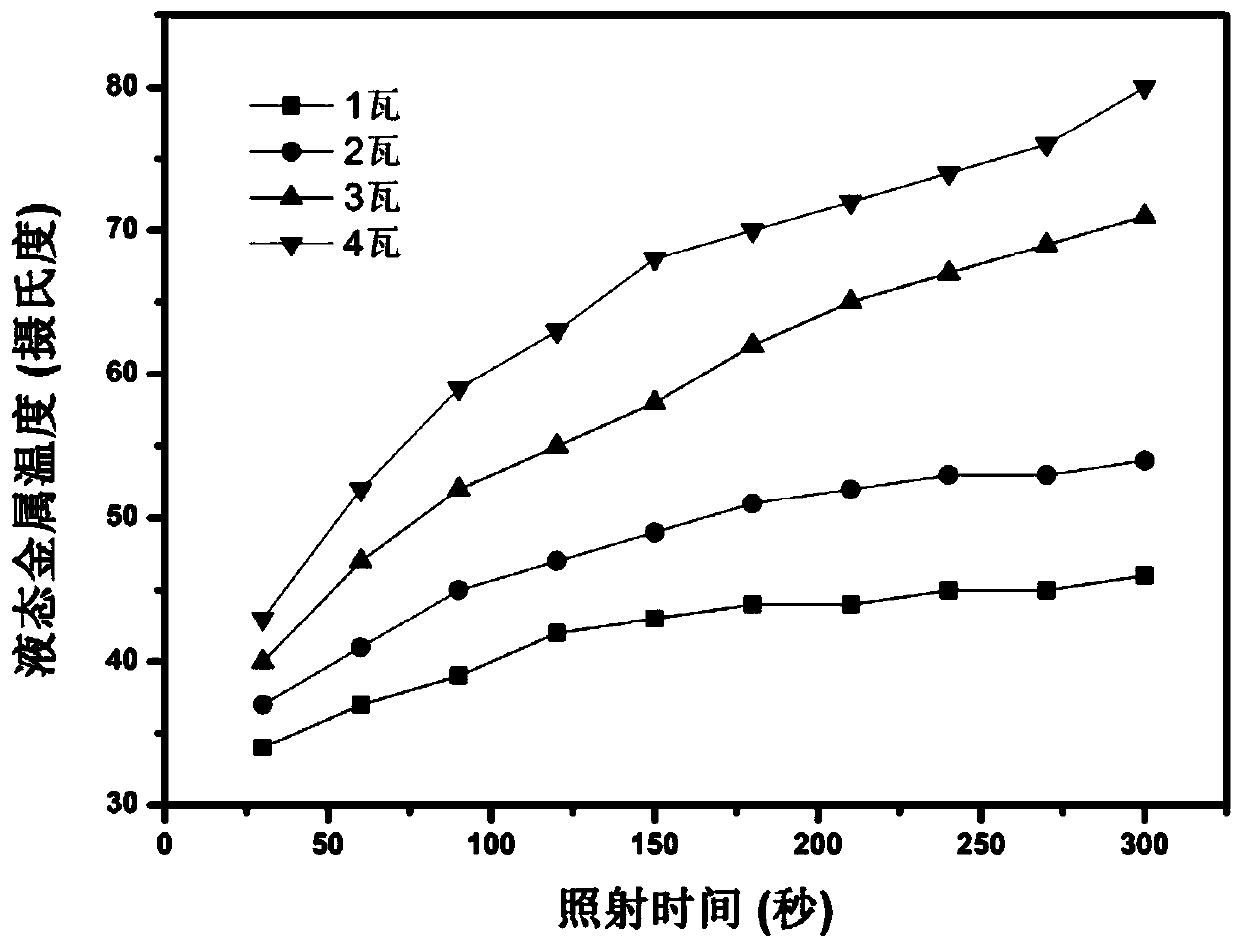

[0043] Step (3): small bubbles are generated on the surface of the irradiated liquid metal, and gradually gather above the liquid metal to form large bubbles, and the growth rate of the large bubbles is controlled by adjusting the laser intensity and irradiation time;

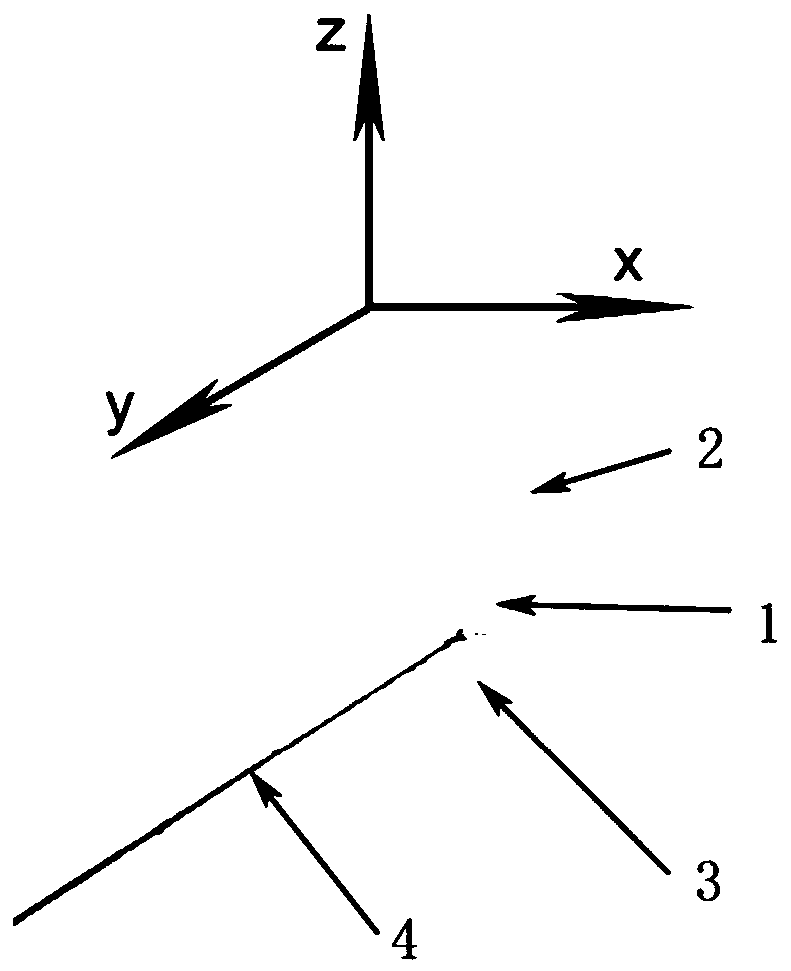

[0044] Step (4): The large bubbles carry the liquid metal up, and the movement direction of the liquid metal and the bubble combination is controlled by adjusting the laser irradiation position.

[0045] Further, the ionic liquid in step (1) is composed of cation A m+ and anion B n- composed of:

[0046] A m+ Is 1-ethyl-3-methylimidazolium cation;

[0047] B n- For dihyd...

specific Embodiment 2

[0054] A method for controlling the movement of a liquid metal with a laser in an ionic liquid, comprising the steps of,

[0055] Step (1): Submerging the liquid metal into a glass container containing an ionic liquid;

[0056]Step (2): irradiating the liquid metal immersed in the ionic liquid through the glass container with a laser;

[0057] Step (3): small bubbles are generated on the surface of the irradiated liquid metal, and gradually gather above the liquid metal to form large bubbles, and the growth rate of the large bubbles is controlled by adjusting the laser intensity and irradiation time;

[0058] Step (4): The large bubbles carry the liquid metal up, and the movement direction of the liquid metal and the bubble combination is controlled by adjusting the laser irradiation position.

[0059] Further, the ionic liquid in step (1) is composed of cation A m+ and anion B n- composed of:

[0060] A m+ Is 1-butyl-3-methylimidazolium cation;

[0061] B n- for bisulf...

specific Embodiment 3

[0067] A method for controlling the movement of a liquid metal with a laser in an ionic liquid, comprising the steps of,

[0068] Step (1): Submerging the liquid metal into a glass container containing an ionic liquid;

[0069] Step (2): irradiating the liquid metal immersed in the ionic liquid through the glass container with a laser;

[0070] Step (3): small bubbles are generated on the surface of the irradiated liquid metal, and gradually gather above the liquid metal to form large bubbles, and the growth rate of the large bubbles is controlled by adjusting the laser intensity and irradiation time;

[0071] Step (4): The large bubbles carry the liquid metal up, and the movement direction of the liquid metal and the bubble combination is controlled by adjusting the laser irradiation position.

[0072] Further, the ionic liquid in step (1) is composed of cation A m+ and anion B n- composed of:

[0073] A m+ Is 1-pentyl-3-methylimidazolium cation;

[0074] B n- It is hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com