Arc discharge type double-screw bolt welding gun

A stud welding and drawn arc technology, applied in arc welding equipment, electrode characteristics, welding equipment, etc., can solve the problems of high labor intensity and low efficiency of manual stud welding, and achieve the effect of improving welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

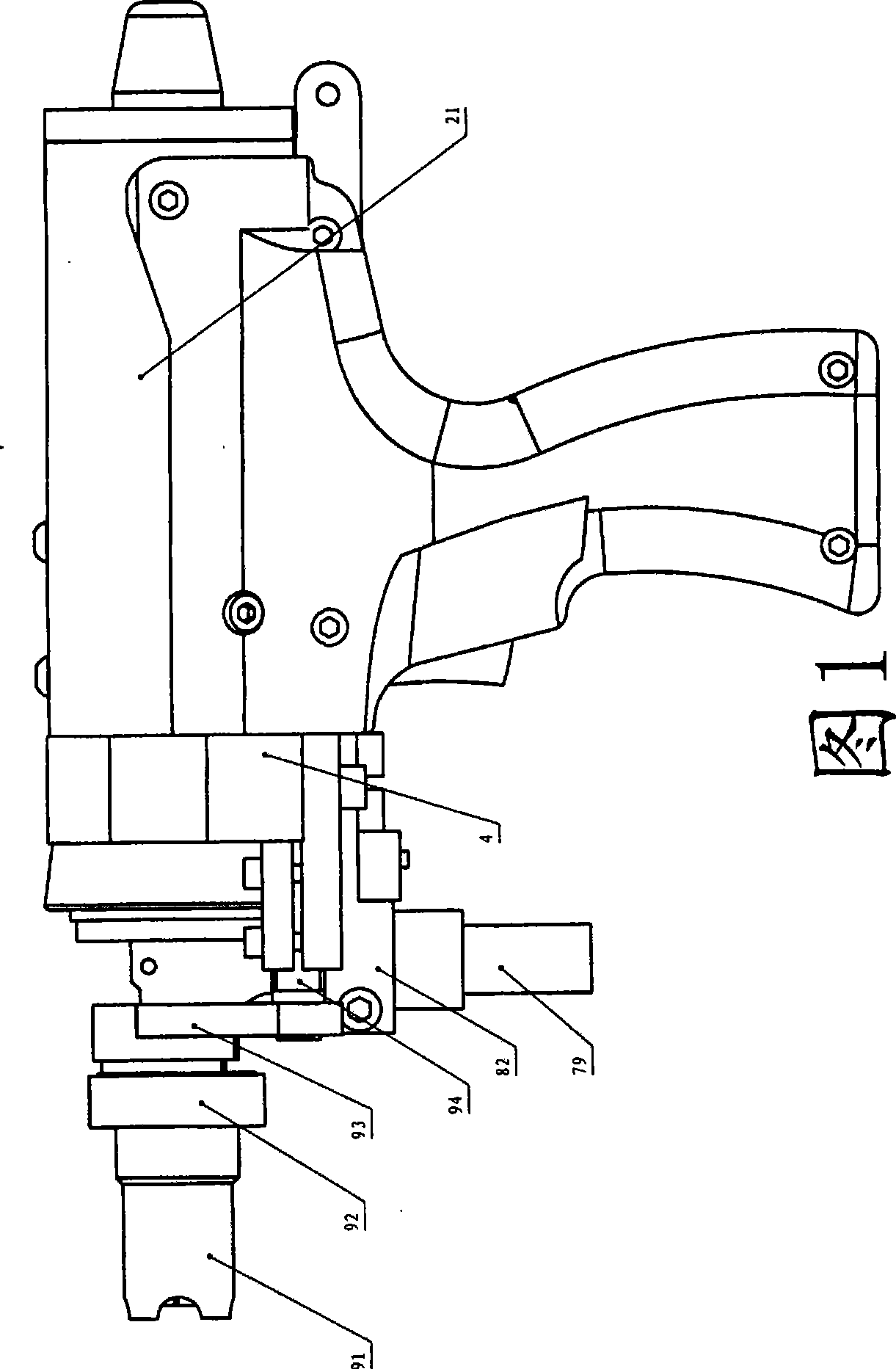

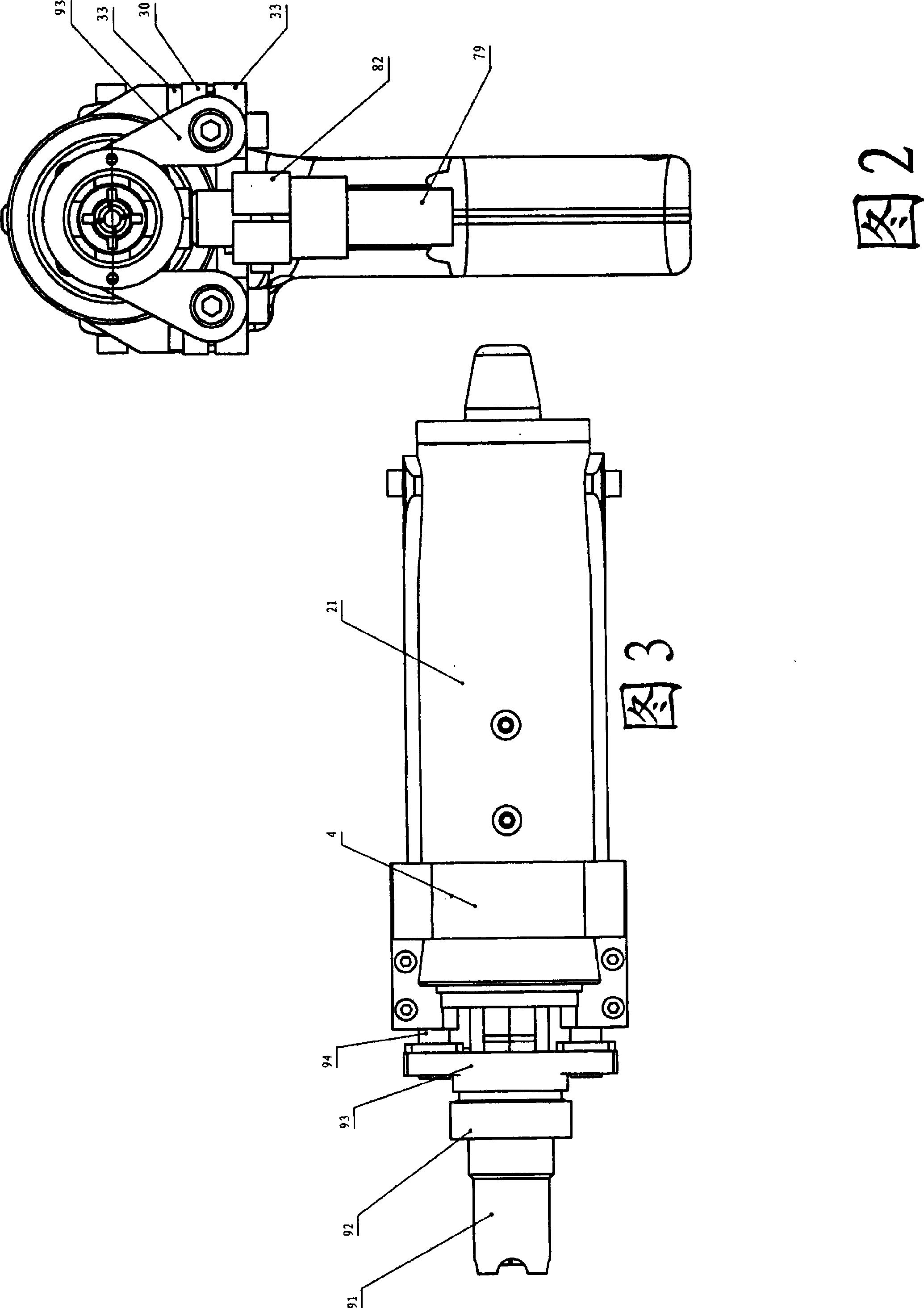

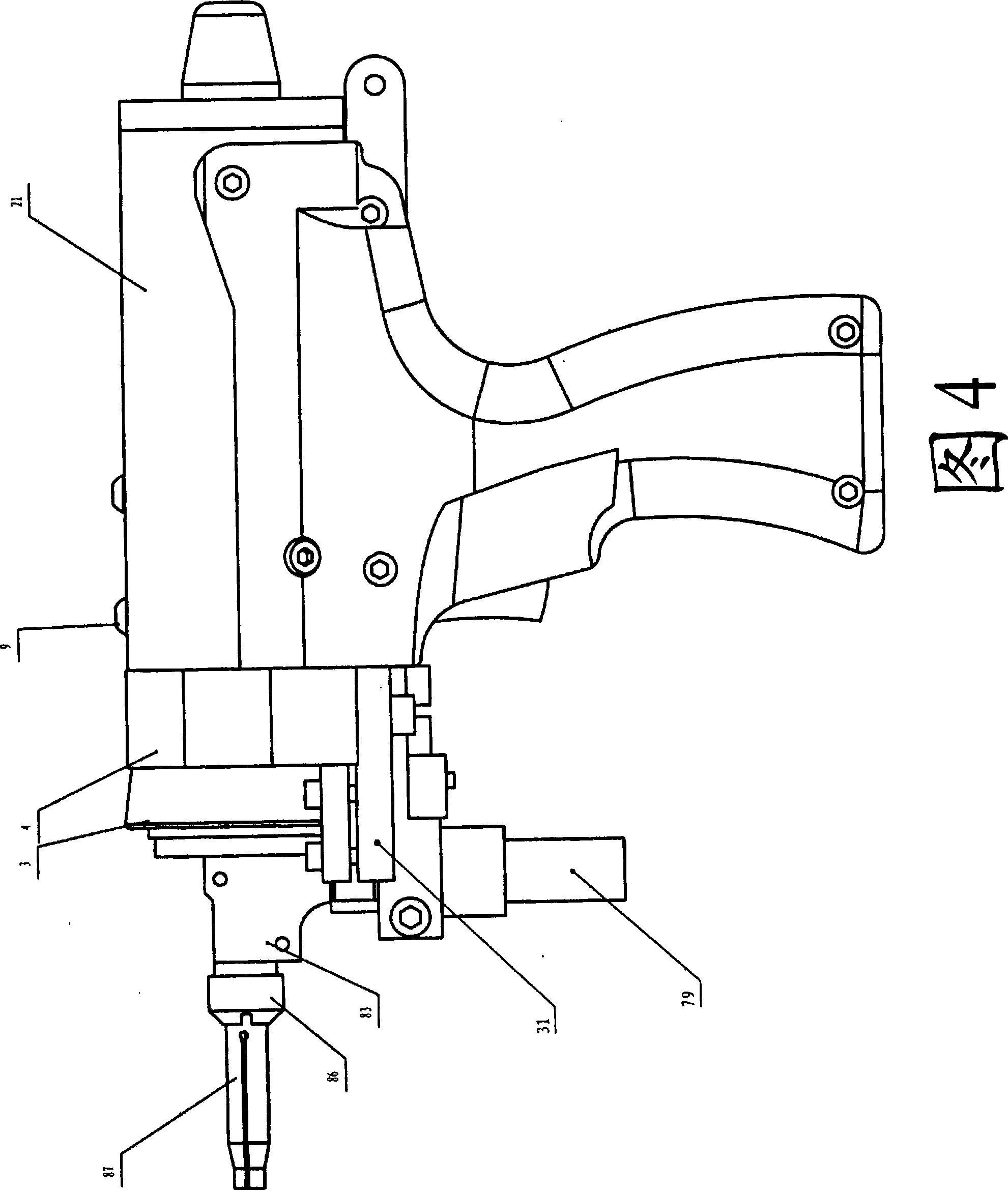

[0035] In the embodiments of the drawn arc stud welding torch of the present invention shown in FIGS. 1 to 18 , the drawn arc stud welding torch is mainly composed of two parts: a fixed assembly and a movable assembly.

[0036] The fixing assembly includes a body group, an electromagnet 20 and an anti-splash set. The body group includes a casing 21 , a sliding sleeve 4 fixed in the casing 21 with screws 9 and an end cover 23 fixed at the rear end of the casing 21 . The electromagnet 20 is installed at the rear of the inner cavity of the casing 21 and fixed on the end cover 23 by screws and nuts 22 . The anti-splash cover set comprises an anti-splash cover 91, a locking nut 92, a support frame 93, and a guide rod 94. Anti-splash cover 91 is fixed on the front end of support frame 93 by lock nut 92, and support frame 93 is connected with the front end of sliding sleeve 4 by 2 guide rods 94, and 2 guide rods 94 are parallel with the axis of movable assembly, press plate 30 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com