Steel stud and thick aluminum plate frictional stud welding method

A welding method and stud technology, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problem of low pass rate of stud welding, easy to produce defects, and can not solve the problem of large diameter studs and thick studs. Metal substrate welding and other problems, to achieve the effect of avoiding solidification cracks, good welding quality and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

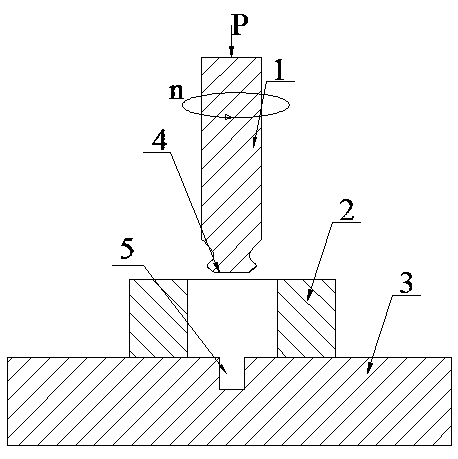

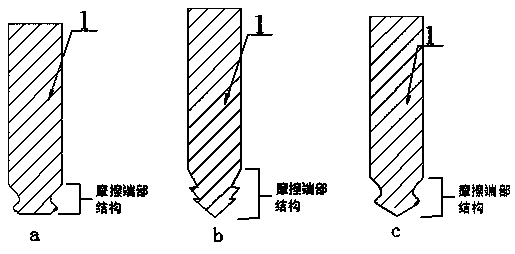

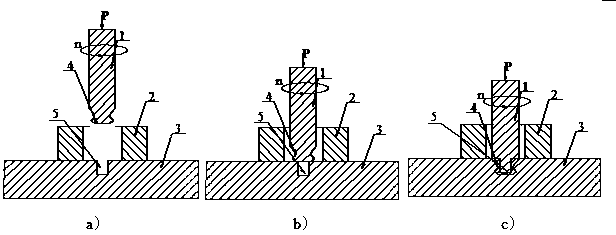

[0034] Example 1, Weld a 30CrNi3MoV solid steel stud with a diameter of 8mm and a length of 80mm, and the end of the stud is as figure 2As shown in -a, the diameter of the end gradually becomes smaller, and there is an annular groove in the circumferential direction, the length of the end of the stud is 10mm, and the finished welded joint of 6061 aluminum alloy with a plate thickness of 15mm is an example:

[0035] Step 1: Processing the end of the steel stud 1, the diameter of the end gradually becomes smaller, and the top of the end is a planar structure, and there is an annular groove in the circumferential direction, the surface of the aluminum plate 3 is processed with a preset hole, and the sleeve 2 is respectively clamped at the predetermined position ; Step 2, start the power supply, the stud rotates, the rotating speed is 1200r / min, and work downwards. After the steel stud contacts the aluminum plate, stop the work, and the steel stud rubs against the aluminum plate...

Embodiment 2

[0036] Example 2, To weld a 30CrNi3MoV solid stud with a diameter of 12mm and a length of 80mm, the end of the stud is as figure 2 As shown in -b, the diameter of the end gradually decreases, and the top of the end is a conical structure, with two annular grooves in the circumferential direction, the length of the end of the stud is 12mm, and the finished welded joint of 6061 aluminum alloy with a plate thickness of 20mm For example:

[0037] Step 1, processing the end of the steel stud 1, the diameter of the end gradually becomes smaller, and there are two annular grooves in the circumferential direction, the surface of the aluminum plate 3 is processed with preset holes, and the sleeves 2 are respectively clamped at predetermined positions; Step 2, start the power supply, The stud rotates at a speed of 900r / min, and works downward. The steel stud and the aluminum plate contact and stop working. The steel stud and the aluminum plate rub for 4 to 8 seconds, so that the stee...

Embodiment 3

[0038] Example 3, To weld a 30CrNi3MoV solid stud with a diameter of 16mm and a length of 80mm, the end of the stud is as figure 2 As shown in -c, the diameter of the end gradually becomes smaller, and the top of the end is a conical structure, with an annular groove in the circumferential direction, the length of the end of the stud is 14mm, and the finished welded joint of 6061 aluminum alloy with a plate thickness of 25mm is example:

[0039] Step 1, processing the end of the steel stud 1, the diameter of the end gradually becomes smaller, and there is an annular groove in the circumferential direction, the surface of the aluminum plate 3 is processed with a preset hole, and the sleeve 2 is respectively clamped at the predetermined position; Step 2, the power is turned on, The stud rotates at a speed of 600r / min, and works downward. After the steel stud contacts the aluminum plate, the work stops. The steel stud rubs against the aluminum plate for 8 seconds, so that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com