Stud flexible welding device and method

A welding device and stud technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of inconvenient replacement of automatic nail feeders and affect the efficiency of automatic stud welding, and achieve fast replacement speed and efficiency. Improve and realize the effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

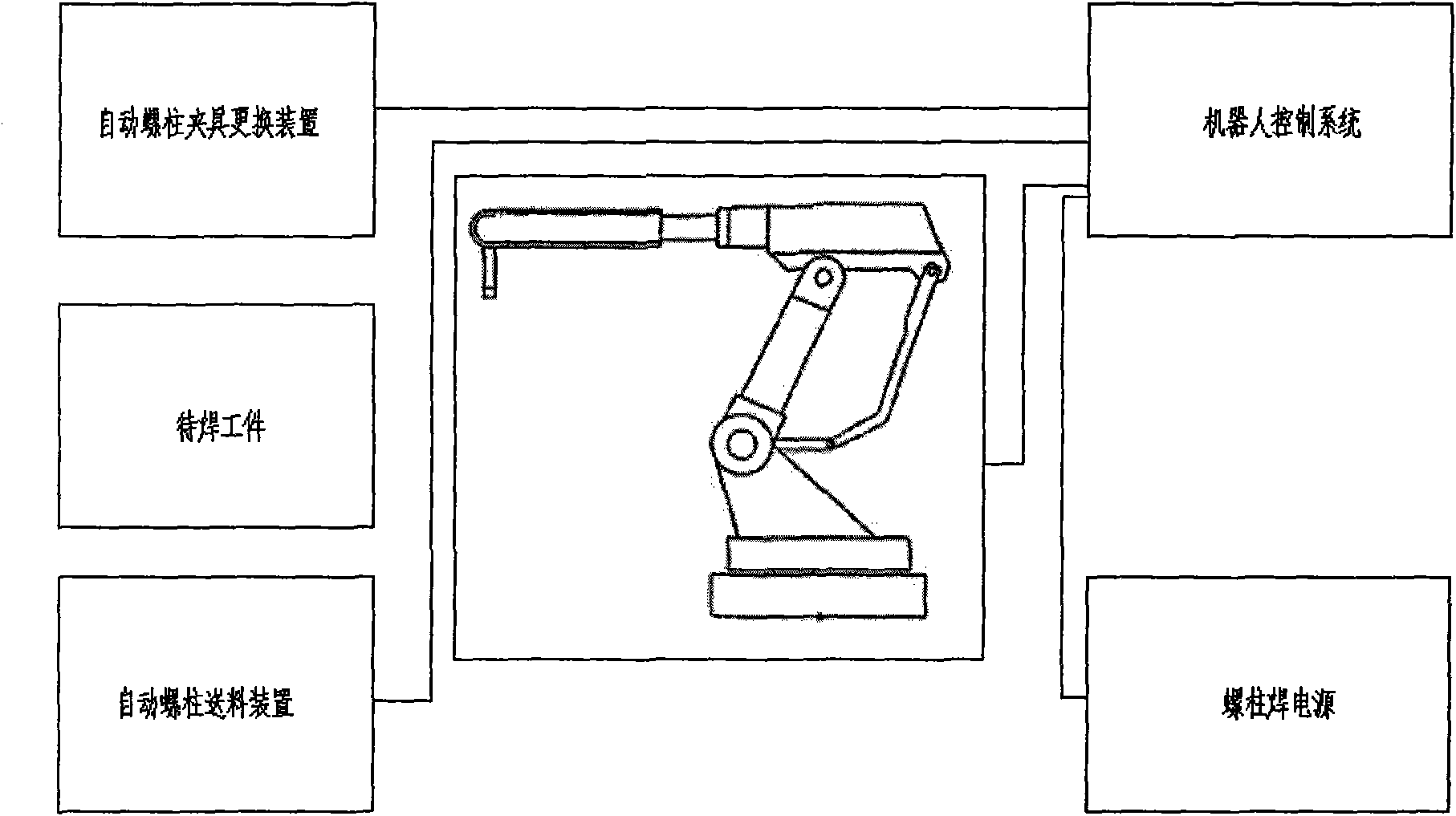

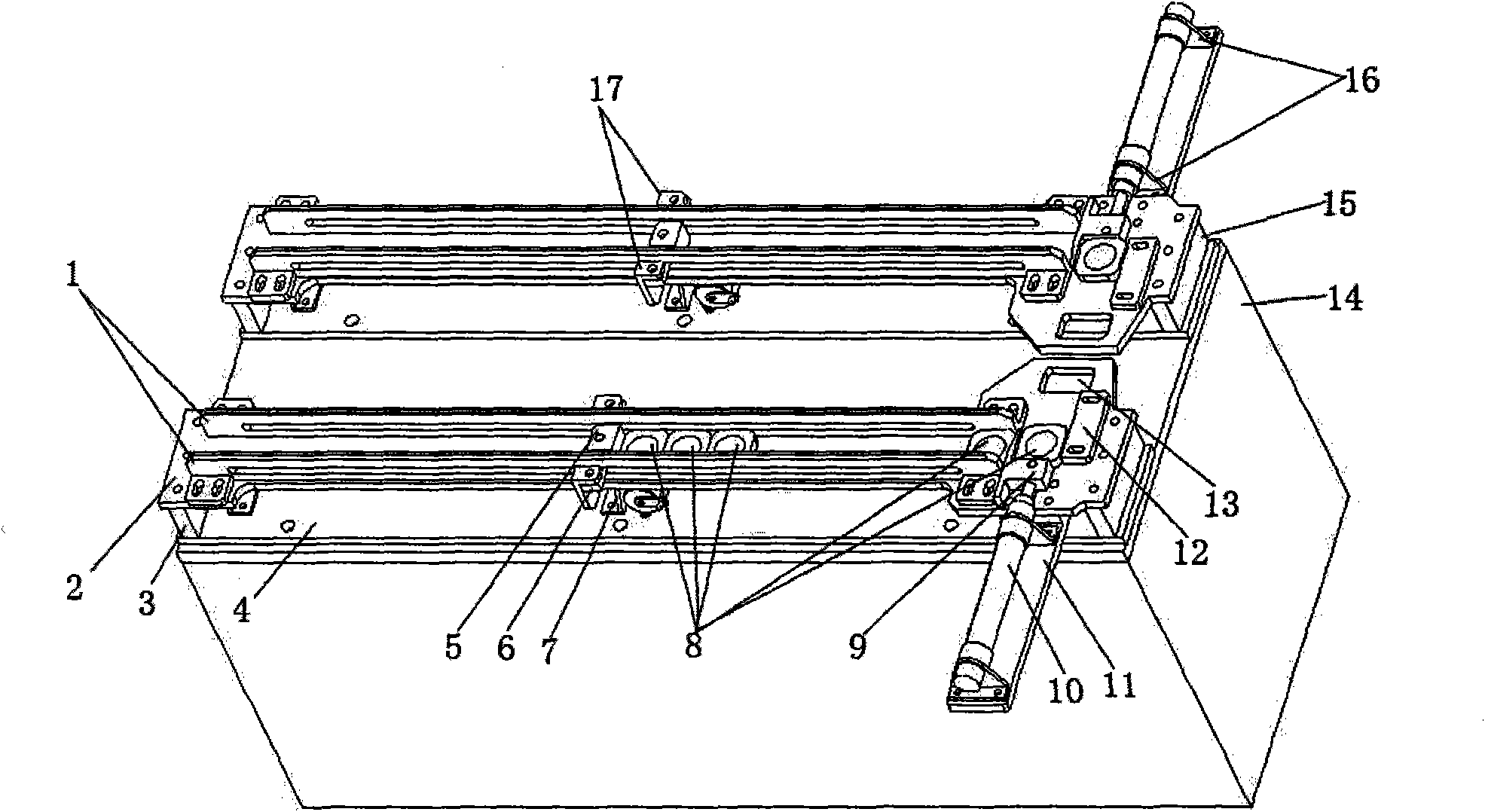

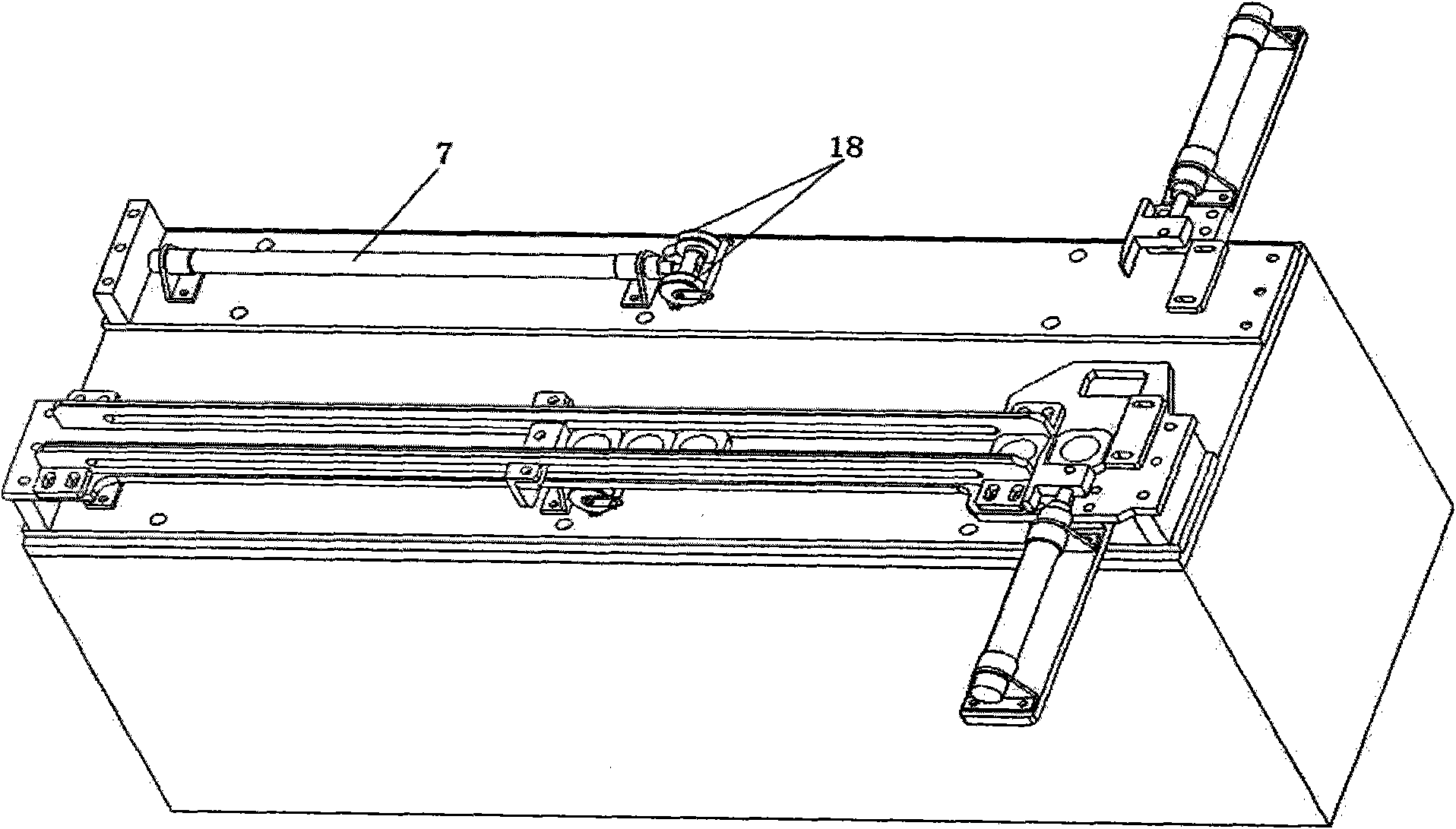

[0051] combine figure 1 , taking the automatic stud welding of a stud with a diameter of 12mm and a length of 60mm and 80mm on a steel plate with a thickness of 20mm as an example. First install the steel studs with a diameter of 12mm and a length of 60mm and 80mm respectively and the ceramic ring matching the studs on the stud fixing plate of the automatic stud feeding device. Then the robot control system sends a series of control signals to complete the entire automatic welding process. The specific steps are as follows: (1) the manipulator moves to the corresponding stage of the automatic stud welding fixture device to install the automatic stud welding fixture device; (2) The manipulator moves to the stud 6 position of the automatic stud feeding device to automatically clamp the stud; (3) The manipulator moves to the designated position to be welded for automatic welding, and completes the entire automatic stud welding process.

Embodiment 2

[0053] combine figure 1 , taking the automatic stud welding of a stud with a diameter of 12 mm and a length of 60 mm and a diameter of 22 mm and a length of 60 mm on a steel plate with a thickness of 20 mm as an example. First, steel studs with a diameter of 12mm and 22mm and the ceramic rings matching the studs are pre-installed on the stud fixing plate of the automatic stud feeding device. Then the robot control system sends out a series of control signals to complete the entire automatic welding process. The specific steps are as follows: (1) The manipulator moves to the stage where the automatic stud welding fixture device matches the stud with a diameter of 12mm, and performs automatic screw welding. Installation of the column welding clamping device; (2) The manipulator moves to the stud 6 position of the automatic stud feeding device to automatically clamp the stud with a diameter of 12mm; (3) The manipulator moves to the designated position to be welded for automatic w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com