Robotic automatic large-diameter stud welding gun

A large-diameter, robotic technology, applied in welding equipment, electrode characteristics, arc welding equipment, etc., can solve the problems of low yield and low efficiency, and achieve low cost, good effect, and good heating and forming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

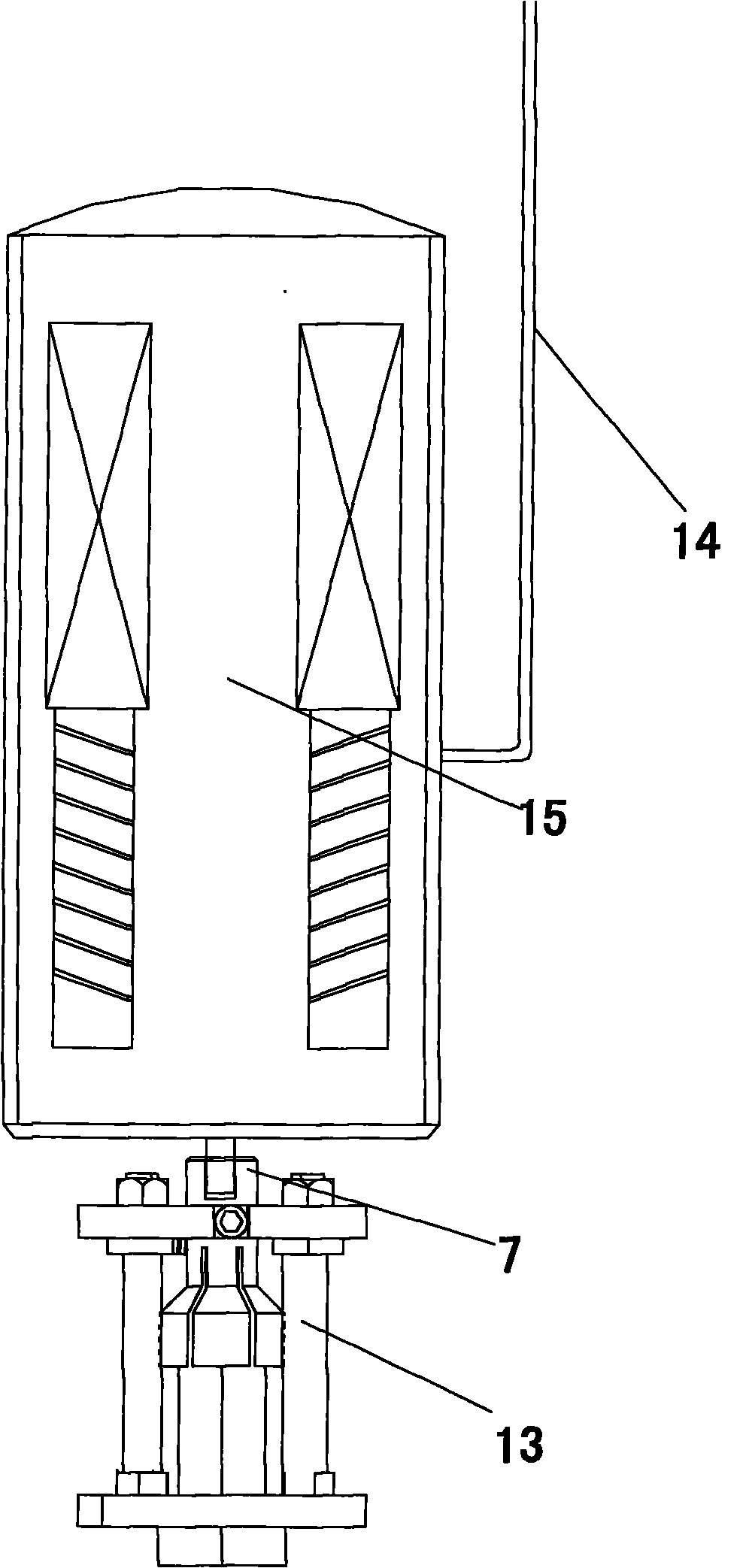

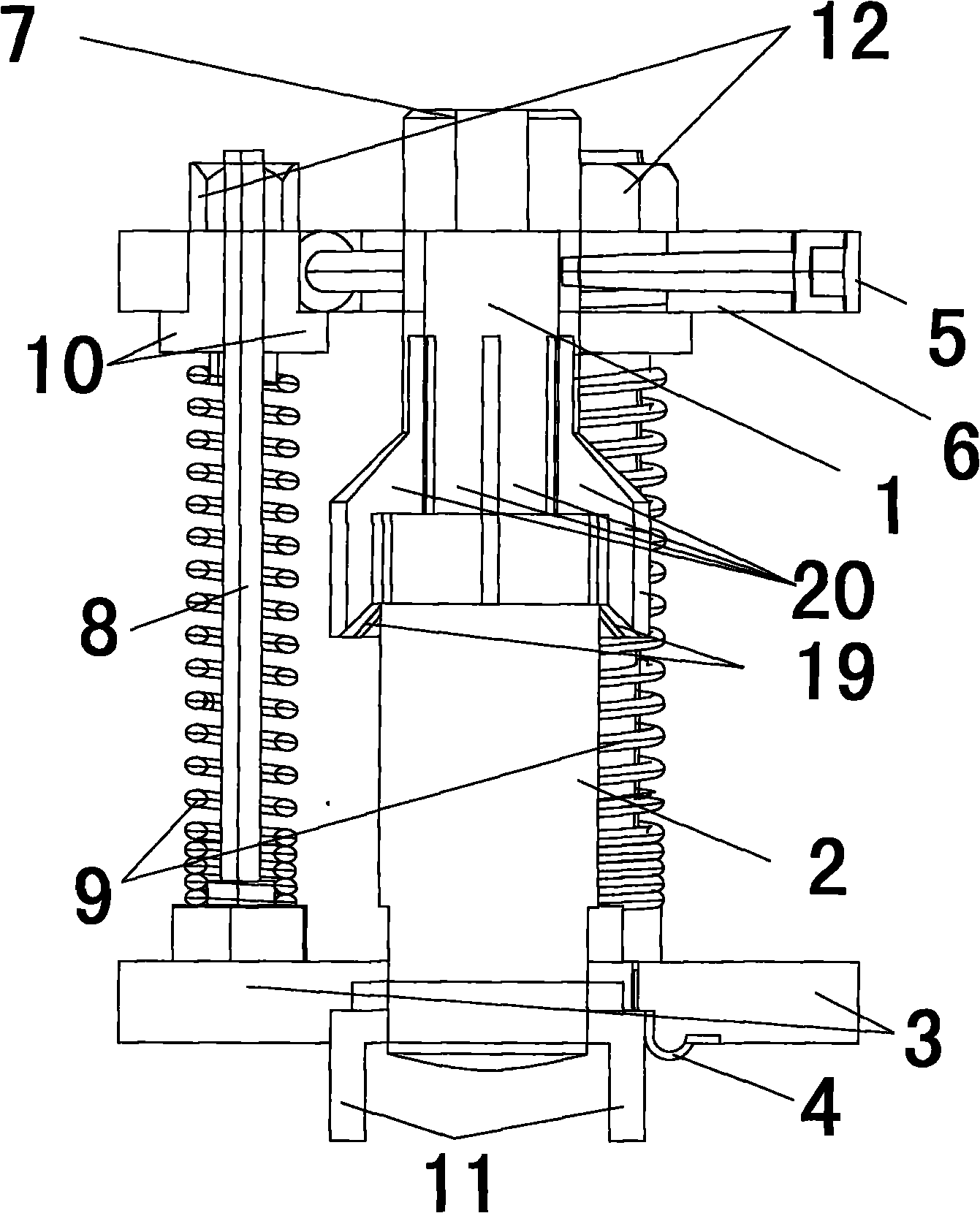

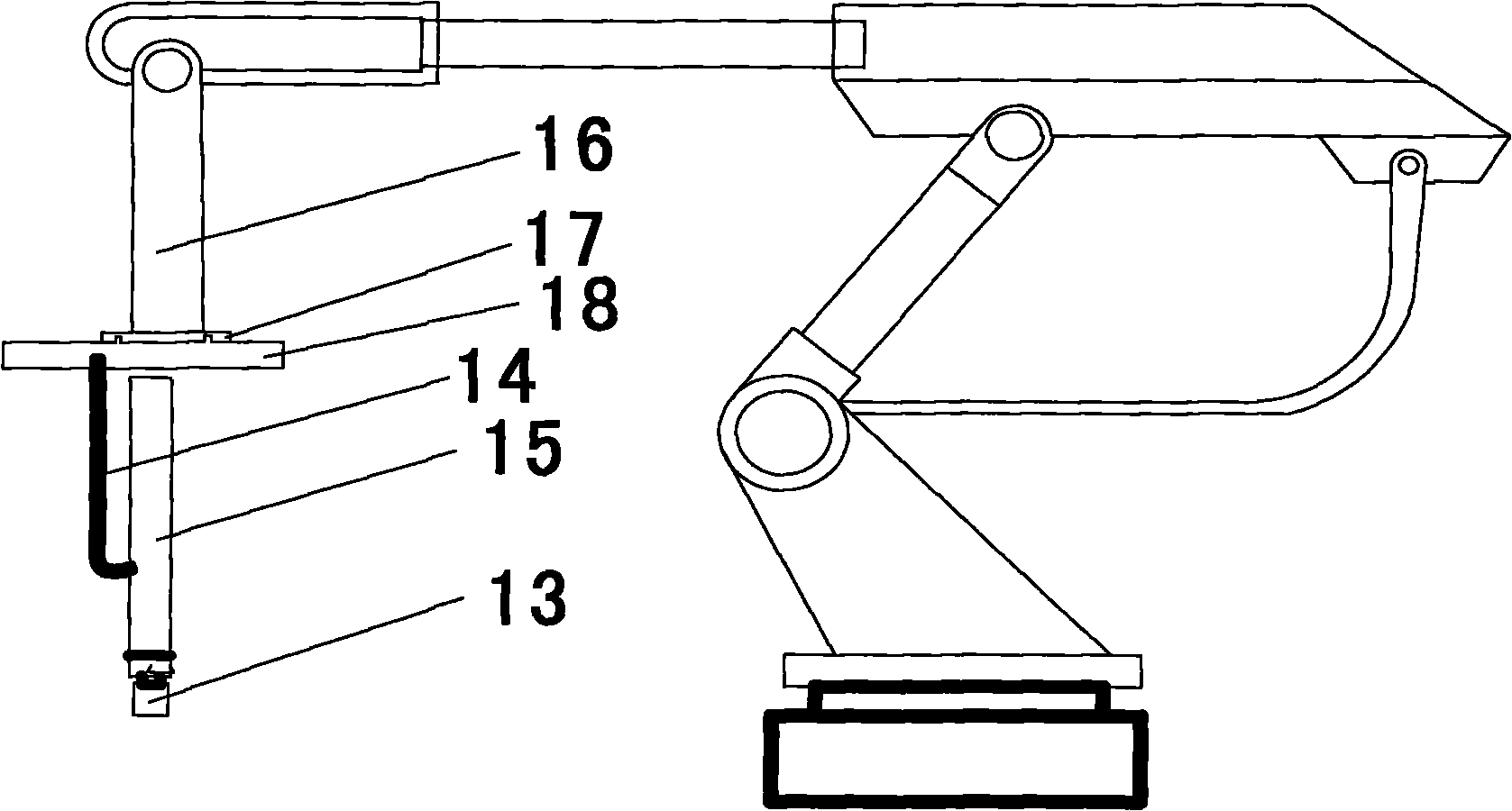

[0012] combine figure 1 , figure 2 , a robot large-diameter automatic stud welding torch of the present invention includes a torch main body 15, a torch clamp 13, and the torch clamp 13 includes an upper plate 6, a lower plate 3, a column 8, a spring 9, a jacket 1 and a shrapnel 4; A jacket 1 is set at the center of the upper plate 6. The jacket 1 penetrates through the upper plate 6 and is fixedly connected with the upper plate 6. A number of elastic blades 20 are arranged at the lower part of the jacket 1. The blades can grasp The stud 2 that goes deep into it, the bottom of the upper plate 6 is provided with a lower plate 3, the upper and lower plates are connected by a column 8, the column 8 is covered with a spring 9, the upper plate 6 can move up and down along the column 8, and the lower plate 3 A through hole is arranged in the center, and the diameter of the through hole is greater than the maximum diameter of the stud 2. A number of elastic pieces 4 are arranged ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com