High and low bin assembling integrated utility tunnel or draining canal

A comprehensive pipe gallery and integrated technology, applied in drainage structures, water conservancy projects, waterway systems, etc., can solve the problems of large cross-sectional size of prefabricated components, difficult waterproofing of seams, difficult construction quality control, etc., to achieve less wet work , Construction quality control is difficult, and the effect of reducing on-site labor and formwork consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

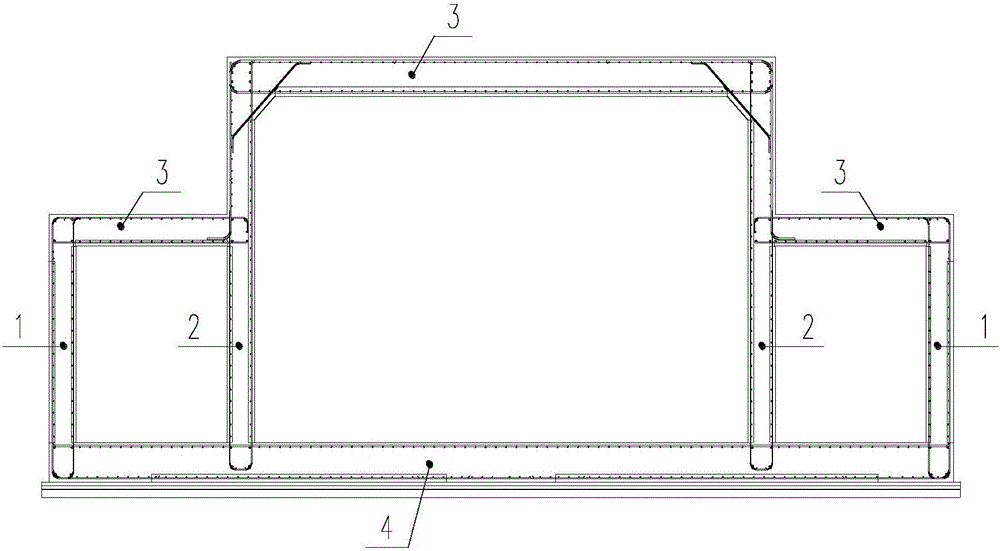

[0040] Such asfigure 1 An integrated integrated pipe gallery or drainage ditch for the upper and lower tanks shown, including the upper and lower tanks superimposed top plate, the superimposed bottom plate 4 or cast-in-place bottom plate, the superimposed outer wall panel 1 and the superimposed high and low tank transition wall panels 2. The laminated roof of the upper cabin and the lower cabin adopts the laminated roof 3 of the same structure. The laminated roof 3 includes the prefabricated roof layer and the cast-in-place layer of the roof. Including the cast-in-place layer of the bottom plate, the laminated exterior wall panel 1 includes the prefabricated layer of the exterior wall panel and the cast-in-place layer of the exterior wall panel, and the laminated upper and lower cabin transition wall panels 2 include the prefabricated layer of the transition wall panel and the cast-in-place layer of the transition wall panel; The bottom plate 4 or the cast-in-place bottom plate...

Embodiment 2

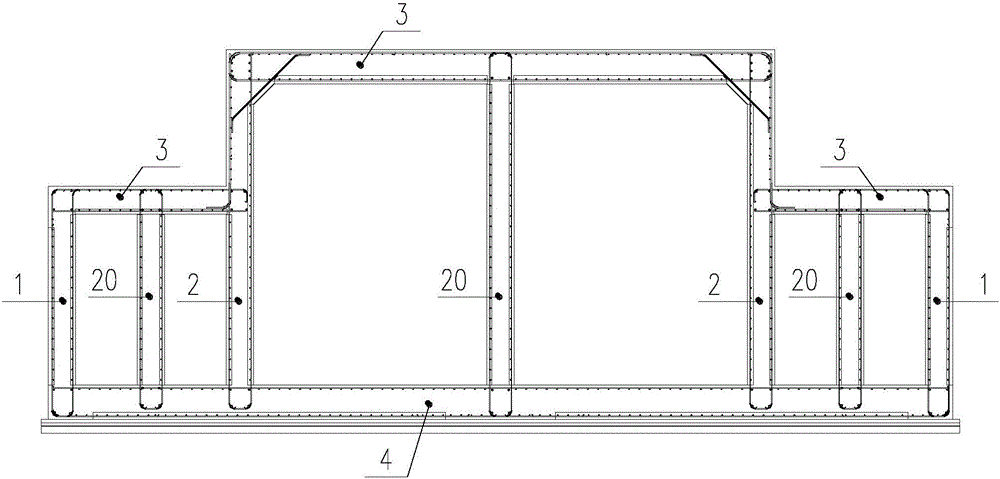

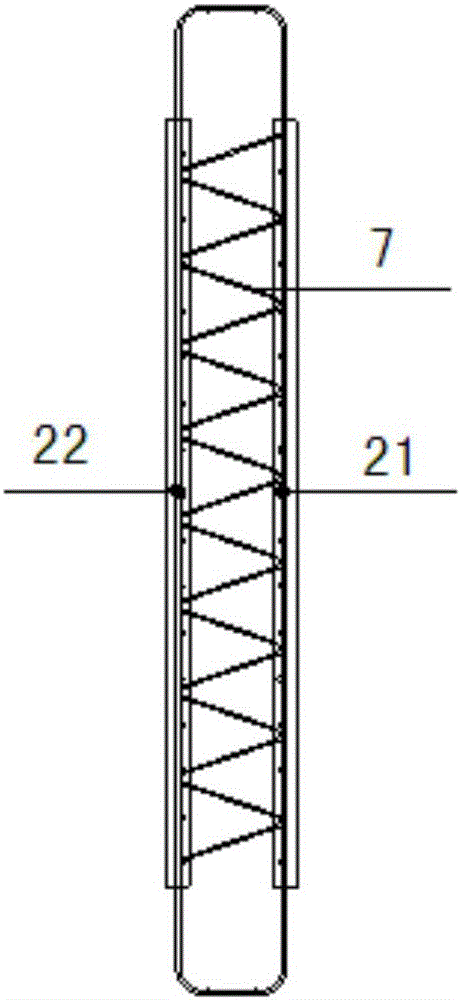

[0049] This embodiment is another form of high and low tank assembly integrated integrated pipe gallery or drainage ditch, see figure 2 , and the structure difference of embodiment 1 is that: in the lower cabin and the upper cabin, a laminated inner wall panel 20 is provided, and the laminated inner wall panel 20 includes the prefabricated layer of the inner wall panel and the cast-in-place layer of the inner wall panel, and the inner wall The slab prefabricated layer is composed of the inner prefabricated slab 21 of the inner wall panel, the outer prefabricated slab 22 of the inner wall panel and the truss reinforcement 7. The upper and lower chords of the truss reinforcement 7 are respectively embedded in the two-layer prefabricated slab and replace the vertical Steel bars, the vertical steel bars protruding from the lower ends of the inner and outer prefabricated slabs are bent and overlapped with each other, and the return bars formed by overlapping are anchored in the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com