Overall high safety door without upper supporting

A security door and bottom support technology, applied in the field of security doors, can solve the problems of high cost, complex structure, full-height security doors without connection structure, etc., and achieve the effect of simple structure, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

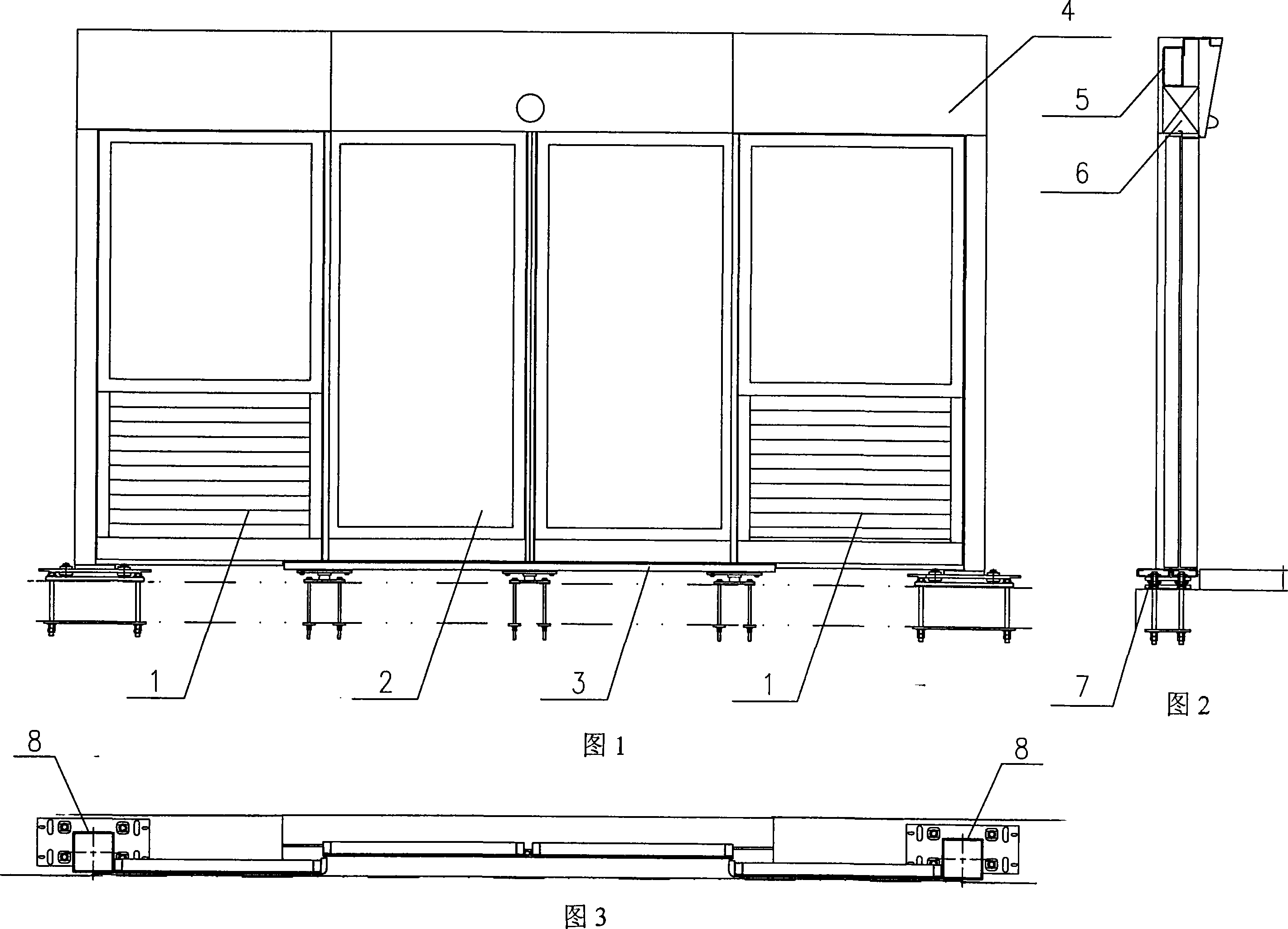

[0010] Referring to the accompanying drawings, its structure includes a fixed door / emergency door 1, a sliding door 2, a sill 3, a top box 4, a beam 5, a load-bearing drive mechanism 6, a bottom support 7 and a column 8, and the lower part of the fixed door / emergency door 1 is installed On the sill 3 or the bottom support 7, the upper part of the fixed door / emergency door 1 is installed on the device of the top box 4, the sill 3 is installed on the bottom support 7, and the sliding door 2 is suspended and installed on the load-bearing driving mechanism 6 at the lower part of the beam 5, Columns 8 are arranged on both sides of the fixed door / emergency door 1 . The bearing driving mechanism 6 drives the sliding door 2 to perform door opening and closing movement.

[0011] The load-carrying drive mechanism (prior art) includes guide rails, mounting brackets, screw rods / belts, connectors, load-carrying trolleys and motors. The function is to carry the door leaf and drive the door...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com