Method for preparing nanocrystalline austenitic stainless steel plate through deep cooling rolling-rapid annealing

A technology of austenitic stainless steel and stainless steel plate, applied in the field of stainless steel manufacturing, can solve the problems of excessive deformation and small sample size, and achieve the effect of solving excessive deformation, simple manufacturing method and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

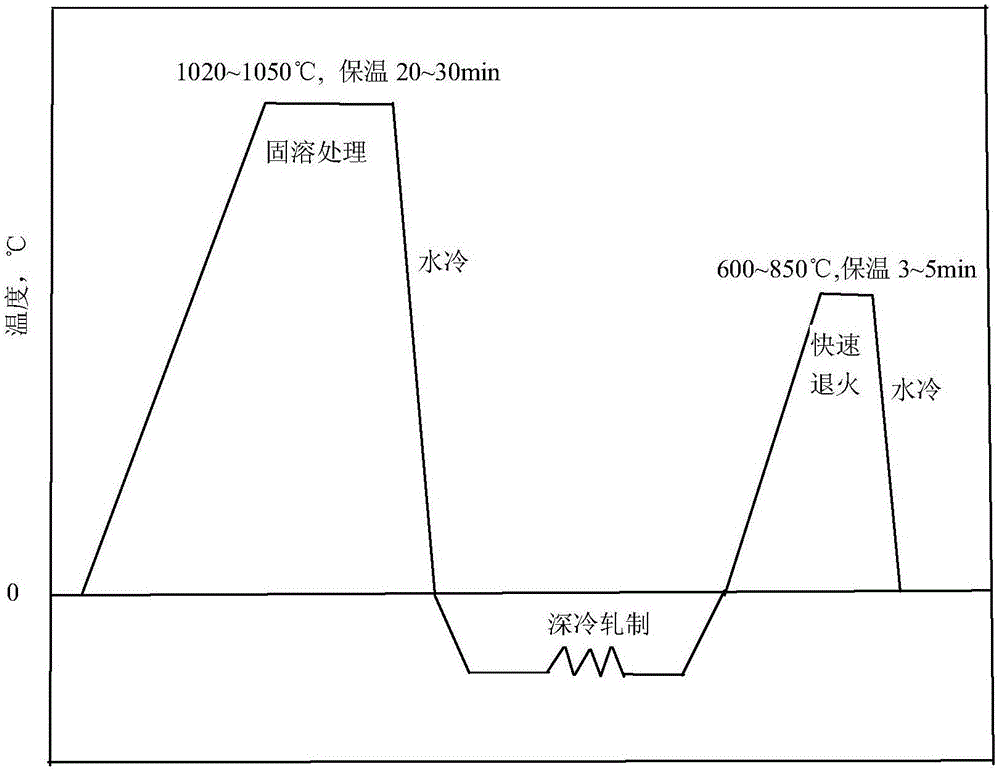

[0044] A method for preparing nanocrystalline austenitic stainless steel plate by cryogenic rolling-rapid annealing, specifically comprising the steps of:

[0045] Step 1, hot rolling:

[0046] (1) Heat a 50mm thick 304 austenitic stainless steel billet at 1150°C for 4 hours; where:

[0047] The 304 austenitic stainless steel plate contains the following components and their mass percentages: C: 0.08%, Si: 0.75%, Mn: 2.0%, Cr: 18.45%, Ni: 8.0%, P: 0.0045%, S: 0.003, the balance is Fe and unavoidable impurities;

[0048](2) The austenitic stainless steel slab after heat preservation is subjected to 7 passes of hot rolling, the starting rolling temperature is 1170°C, the final rolling temperature is 1000°C, the total cumulative reduction rate is 90%, and then the cooling rate is 25°C / s water cooling to 150°C, then air cooling to room temperature to produce a 5mm thick hot-rolled sheet;

[0049] Step 2, cryogenic rolling:

[0050] (1) Solution treatment: Cut the hot-rolled p...

Embodiment 2

[0060] A method for preparing nanocrystalline austenitic stainless steel plate by cryogenic rolling-rapid annealing, specifically comprising the steps of:

[0061] Step 1, hot rolling:

[0062] (1) Heat a 50mm thick 304 austenitic stainless steel billet at 1250°C for 3 hours; where:

[0063] The 304 austenitic stainless steel plate contains the following components and their mass percentages: C: 0.08%, Si: 0.75%, Mn: 2.0%, Cr: 18.45%, Ni: 8.0%, P: 0.0045%, S: 0.003, the balance is Fe and unavoidable impurities;

[0064] (2) The austenitic stainless steel slab after heat preservation is subjected to 7 passes of hot rolling, the starting rolling temperature is 1170°C, the final rolling temperature is 1000°C, the total cumulative reduction rate is 90%, and then the cooling rate is 35°C / s water cooled to 200°C, then air-cooled to room temperature to produce a 5mm thick hot-rolled sheet;

[0065] Step 2, cryogenic rolling:

[0066] (1) Solution treatment: Cut the hot-rolled pl...

Embodiment 3

[0076] A method for preparing nanocrystalline austenitic stainless steel plate by cryogenic rolling-rapid annealing, specifically comprising the steps of:

[0077] Step 1, hot rolling:

[0078] (1) Heat a 50mm thick 304 austenitic stainless steel billet at 1150°C for 4 hours; where:

[0079] The 304 austenitic stainless steel plate contains the following components and their mass percentages: C: 0.08%, Si: 0.5%, Mn: 1.24%, Cr: 19.07%, Ni: 7.98%, P: 0.0068%, S: 0.0062%, the balance is Fe and unavoidable impurities;

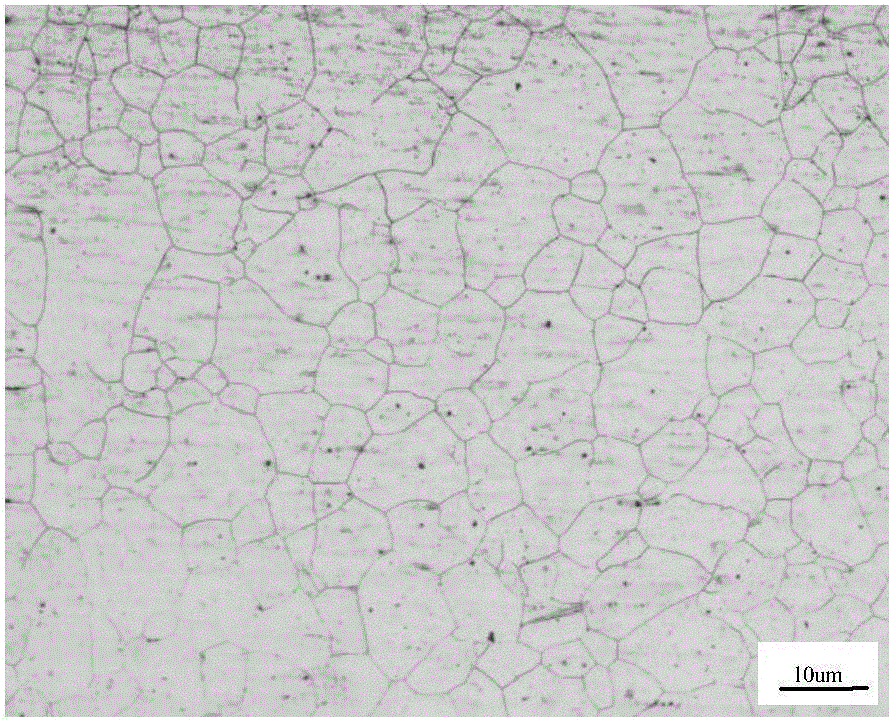

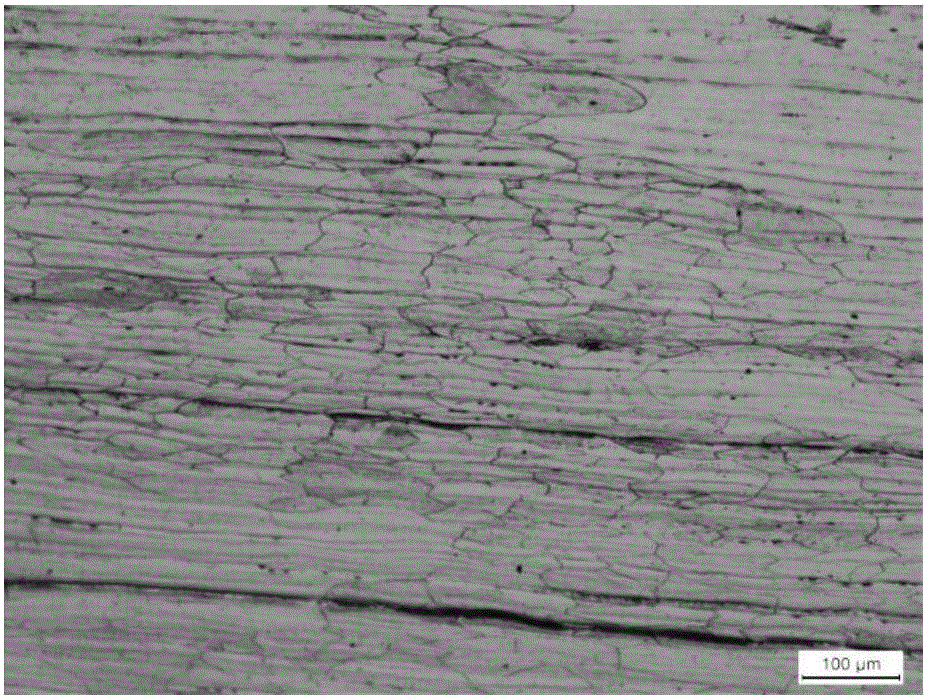

[0080] (2) The austenitic stainless steel slab after heat preservation is subjected to 7 passes of hot rolling, the starting rolling temperature is 1170°C, the final rolling temperature is 1000°C, the total cumulative reduction rate is 90%, and then the cooling rate is 30°C / s of water cooled to 180 ° C, air-cooled to room temperature, made of 5mm thick hot-rolled sheet; the metallographic structure of the hot-rolled sheet is as follows figure 2 shown;

[0081...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com