Chain tightening device

A chain tensioner and rack technology, applied in hand-held tools, manufacturing tools, etc., can solve problems such as low efficiency, low strength, and insufficient load-bearing capacity, so as to reduce intermediate links, strong load-bearing capacity, and work high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

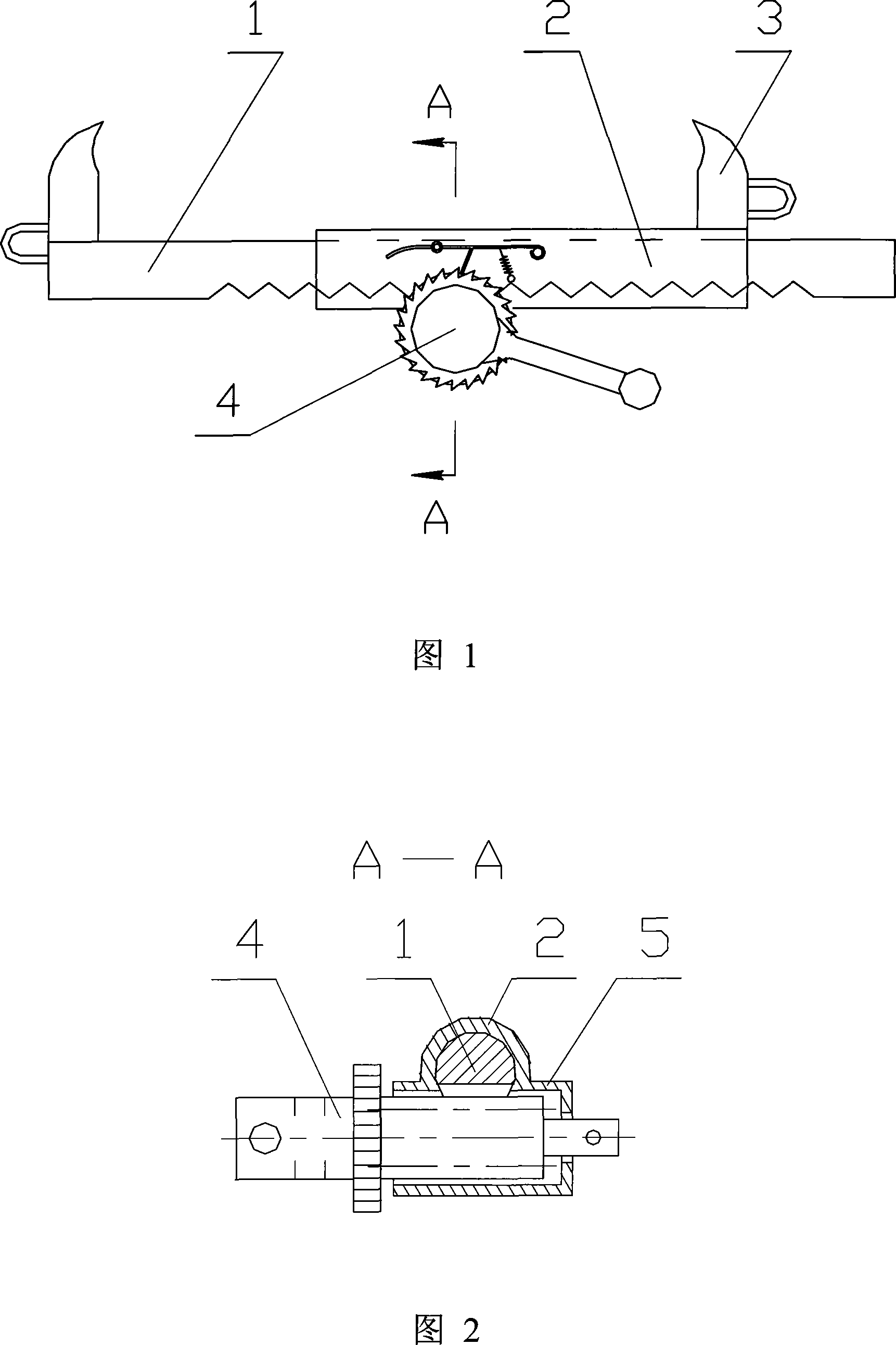

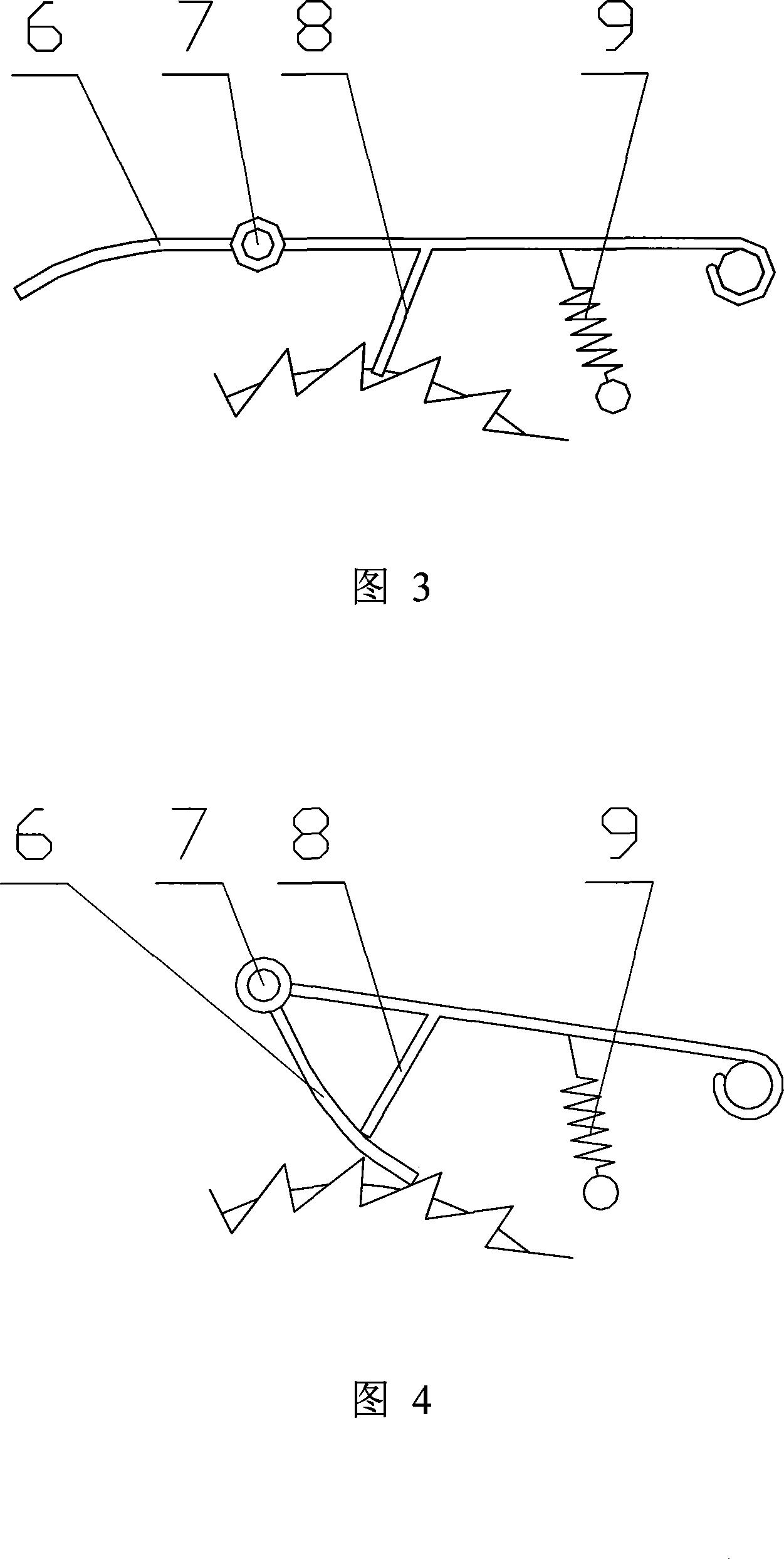

[0013] Shown in Fig. 1 and Fig. 2, the present invention is made up of drag hook 3, force application device, rack 1, pinion, pinion sleeve and non-return mechanism. The rack 1 is installed in the rack sleeve 2, and is slidably matched with the rack sleeve 2. Two drag hooks 3 are respectively welded on the rack 1 and the rack cover 2, and can also be fixed on the rack 1 and the rack cover 2 with bolts. The lower part of the rack sleeve 2 is welded or screwed to the sleeve 5, and the upper part of the sleeve 5 is vertically connected with the lower part of the rack sleeve 2, so that the force applying device is located in the sleeve 5 and fits with the sleeve 5 in a gap. The gear shaft meshes with the exposed rack 1 through the through hole of the freewheel part. The force applying device is made up of rotating shaft 4 and non-return mechanism. One end of the rotating shaft 4 is welded with a rotating handle, and the middle part has a toothed disc, which can be fixed on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com