Enhanced secondary flow-based inertial focus chip

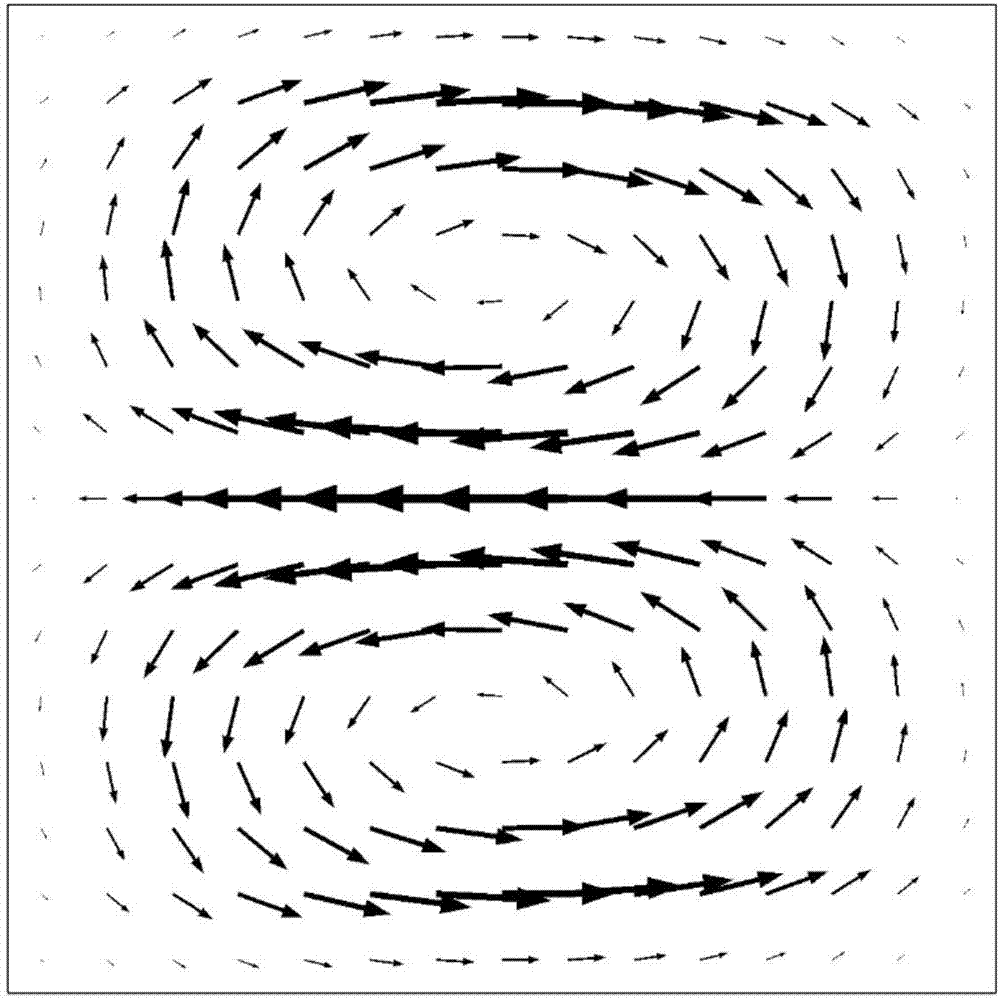

A secondary flow and enhanced technology, applied in the field of microfluidics, can solve the problem of low guiding efficiency of a single secondary flow, and achieve the effect of ensuring success rate, improving strength and enhancing guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

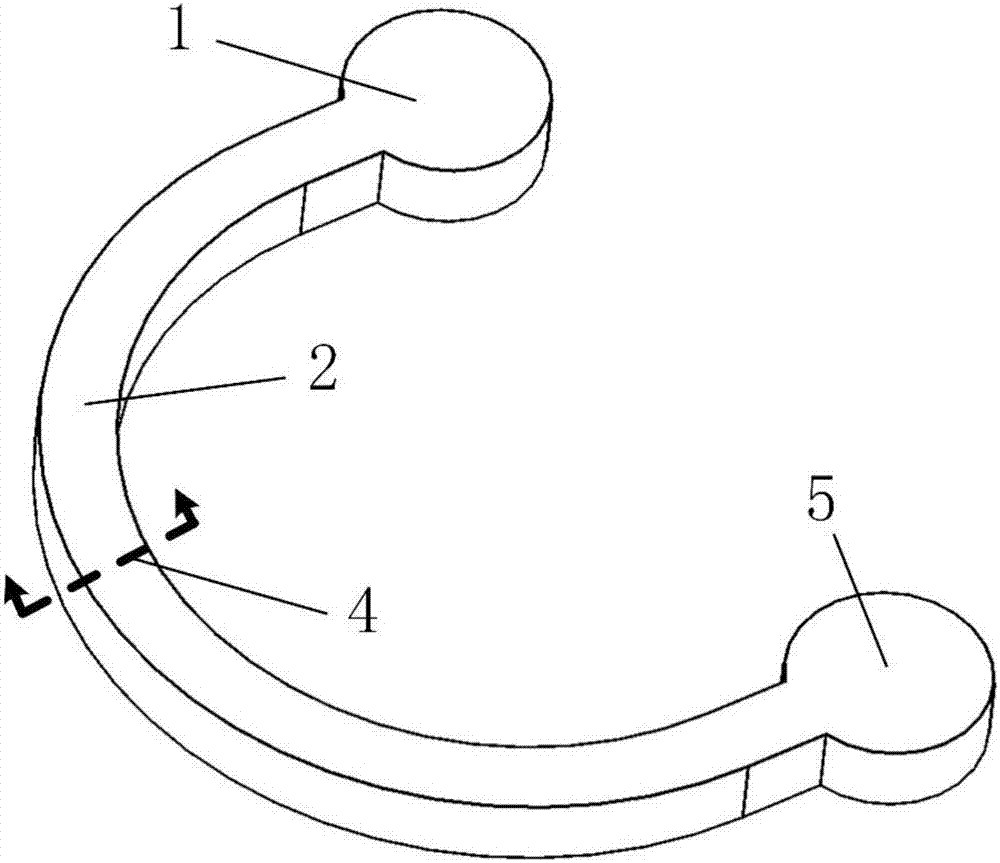

Embodiment 1

[0025] In this embodiment, the inertial focusing chip based on the enhanced secondary flow is formed by bonding two chip layers. Refer to Figure 5 , one of them has a microchannel on the bonding surface of the chip layer, the two ends of the microchannel are respectively connected to the inlet 1 and the outlet 5, and the main channel is a circular microchannel 2, which produces the first secondary flow (Dean flow ); there are several boss structures distributed on the channel wall, which are square in shape, so that the channel is a variable cross-section channel, which produces the second secondary flow (the secondary flow caused by the geometric structure); the boss structure is located in the channel The curved surface of the wall is a convex side, so that the first secondary flow is in the same direction as the second secondary flow; the material of the microfluidic focusing chip is polydimethylsiloxane (PDMS), polymethylmethacrylate ( PMMA), polycarbonate (PC) or glass, ...

Embodiment 2

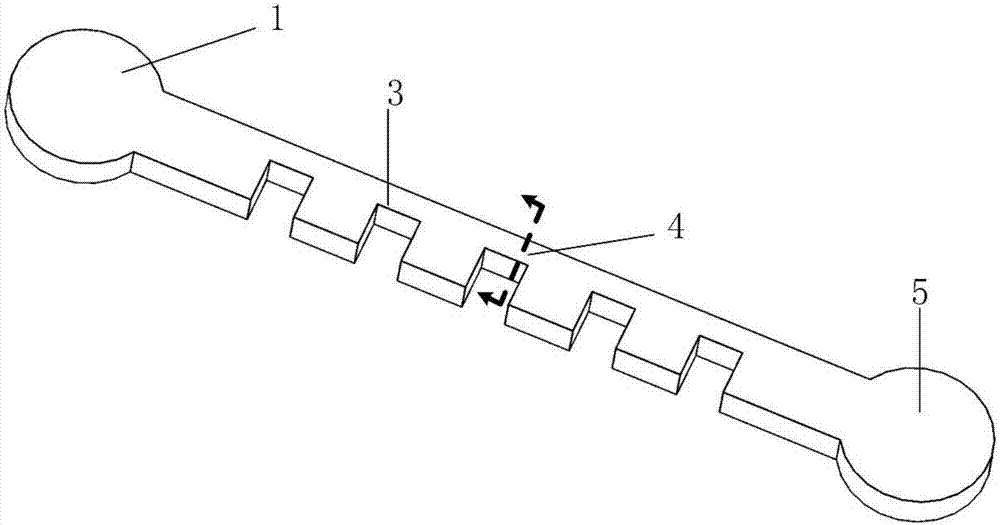

[0039] In this embodiment, the inertial focusing chip based on the enhanced secondary flow is formed by bonding two chip layers. Refer to Figure 10 , one of them has a microchannel on the bonding surface of the chip layer, and the two ends of the microchannel are respectively connected to the inlet 1 and the outlet 5, and the main channel is a curved microchannel, which produces the first secondary flow (Dean flow); There are several boss structures distributed on the wall of the channel, which are cylindrical in shape, so that the channel is a channel with variable cross-section, which generates the second secondary flow (secondary flow caused by geometric structure); the boss structure is located on the channel wall. The curved surface is a convex side, so that the first secondary flow is in the same direction as the second secondary flow; the microfluidic focusing chip material is polydimethylsiloxane (PDMS), polymethylmethacrylate (PMMA ), polycarbonate (PC) or glass, etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com