Method for processing profiled bar with asymmetrical cross section

A processing method and asymmetric technology, applied in the field of rolling processing, can solve the problems of uneven temperature distribution of the section, unstable rolling, difference in roll diameter, etc., and it is easy to ensure the rolling temperature, increase the section size of the billet, reduce the The effect of product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

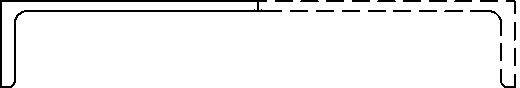

[0035] Example 1: L-shaped steel production

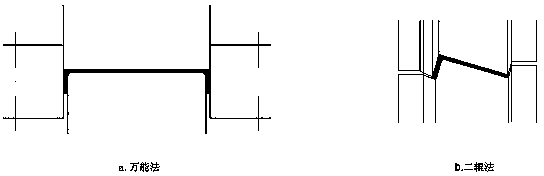

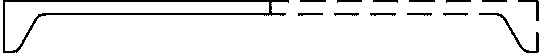

[0036] Make L-shaped steel along the side of the long leg as a mirror image pairing combination to form a left-right symmetrical parallel leg groove section (see attached figure 1 ). Take this as the target product for universal rolling (see attached figure 2 ), the rolled semi-finished product is longitudinally centered and split by a CNC flame cutting machine (simple straightening may be required), and two finished products with the same size and shape can be obtained (see attached image 3 ). This method can be used to produce qualified L-shaped steel products that meet the requirements of GB / T 706-2008 "Hot-rolled Sectional Steel" or relevant foreign standards such as Japan and Europe.

Embodiment 2

[0037] Embodiment 2: Bulb flat steel production

[0038] The mirrored pairing combination is carried out along the waist of the spherical flat steel to form a left-right symmetrical short-leg groove-shaped section (see attached Figure 4 ). Taking this as the target product, organize universal rolling production (see attached Figure 5 ), the rolled semi-finished product is longitudinally centered and split by a CNC air plasma cutting machine, and after simple straightening treatment, two finished products with the same size and shape can be obtained (see attached Figure 6 ). The method can be used to produce qualified flat bulb steel products that meet the requirements of GB / T9945-2001 "Hot-rolled flat bulb steel" and other standards.

Embodiment 3

[0039] Embodiment 3: Production of hot-rolled section steel for elevator guide rails

[0040] The elevator guide rail steel is paired and combined along the rail head to form a biaxially symmetrical special-shaped I-shaped section (see attached Figure 7 ). Take this as the target product for universal rolling (see attached Figure 8 ), the rolled semi-finished product is longitudinally centered and split by a CNC flame cutting machine (simple straightening may be required), and two finished products with the same size and shape can be obtained (see attached Figure 9 ). This method can be used to produce qualified elevator guide rail steel products that meet the requirements of YB / T 157-1999 "Hot Rolled Section Steel for Elevator Guide Rails" and other standards.

[0041] In addition, there are steel window steel, hot-rolled section steel for track shoes, plowshare steel, fishplate for rail, T-shaped steel and many other asymmetric and complex section special-shaped materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com