A method for controlling the flatness of the secondary cold rolling of a six-high UCM rolling mill

A technology of secondary cold rolling and shape control, applied in contour control and other directions, to achieve the effect of improving the physical quality of the shape, increasing the qualified rate of the shape quality, and improving the rolling conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

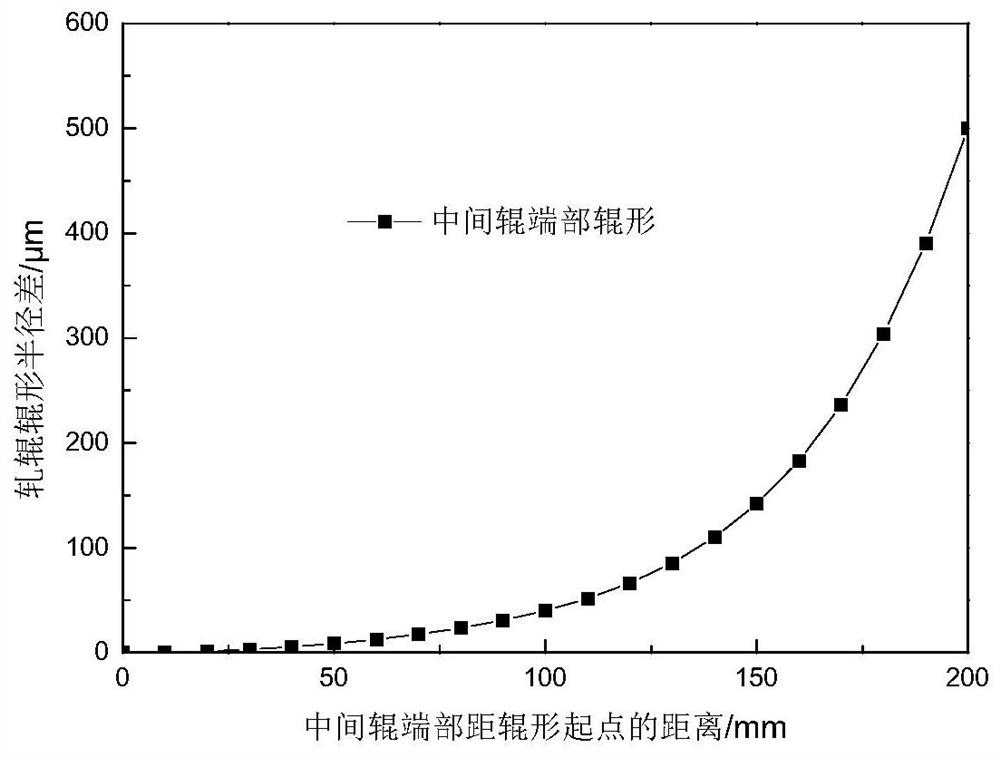

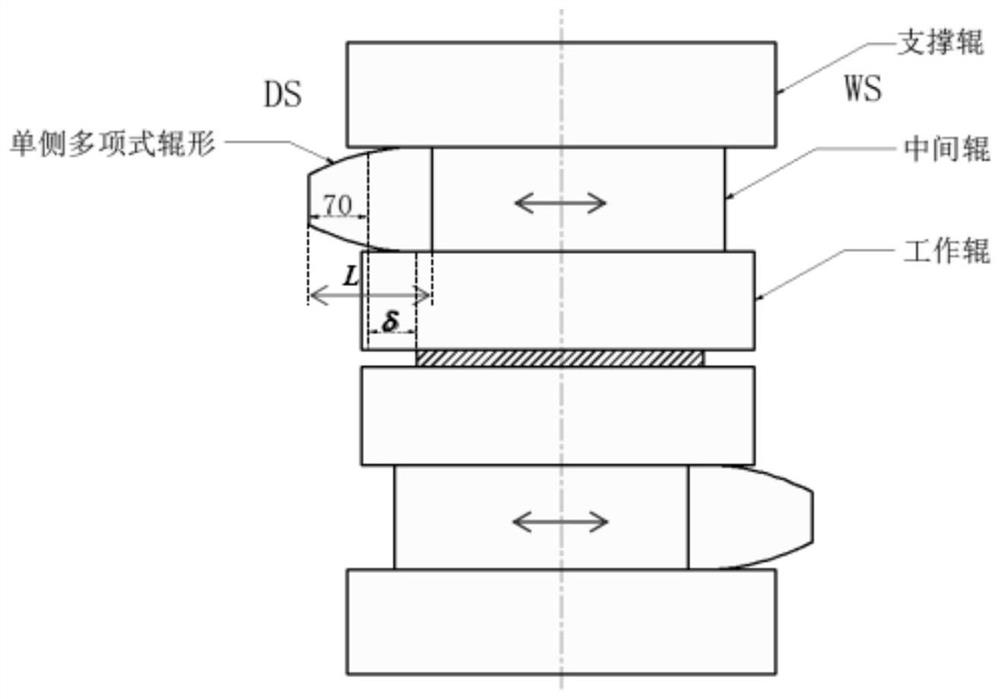

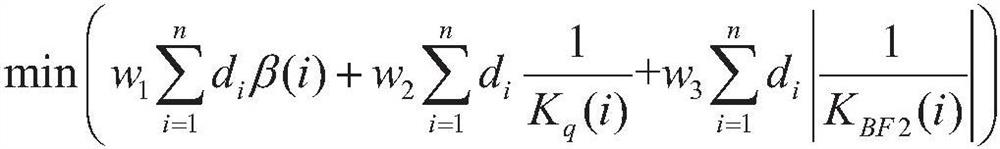

[0082] Industrial test was carried out on the 1220DCR unit of a certain factory, using the small roll production mode to continuously produce 15 coils of strip steel with the steel type MRDR-8CA, the width B of 934mm, and the thickness H of 0.200mm. During the production process, the δ setting of the 1# frame 25mm, 2# frame δ is set to 10mm, and the absolute roll shifting amount of the intermediate roller is determined according to formula (1) as 1# frame S=192mm, and 2# frame S=177mm.

Embodiment 2

[0084] Industrial test was carried out on the 1220DCR unit of a certain factory, and the small roll production mode was used to continuously produce 12 coils of strip steel with a steel grade of TH580, a width B of 893mm, and a thickness H of 0.201mm. During the production process, the δ of the 1# rack was set to 25mm , 2# frame δ is set to 10mm, and the absolute roll shifting amount of the intermediate roller is determined according to formula (1) as 1# frame S=171.5mm, and 2# frame S=156.5mm.

[0085] Using the patented strip shape control method and device, the secondary cold rolling unit is equipped with a single-side intermediate roll profile curve through the intermediate roll, combined with the roll shifting adjustment strategy of the intermediate roll and the bending technology of the work roll and the intermediate roll, effectively improving the rolling process. Control conditions improve the shape control performance of the rolling mill, which is more conducive to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com