A kind of high temperature pattern stability PVC film and its preparation method and application

A stable, PVC resin powder technology, applied in the field of high-temperature pattern-stabilized PVC film and its preparation, can solve problems such as whitening, film brightening, and cracking, and achieve good impact resistance and excellent high-temperature stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

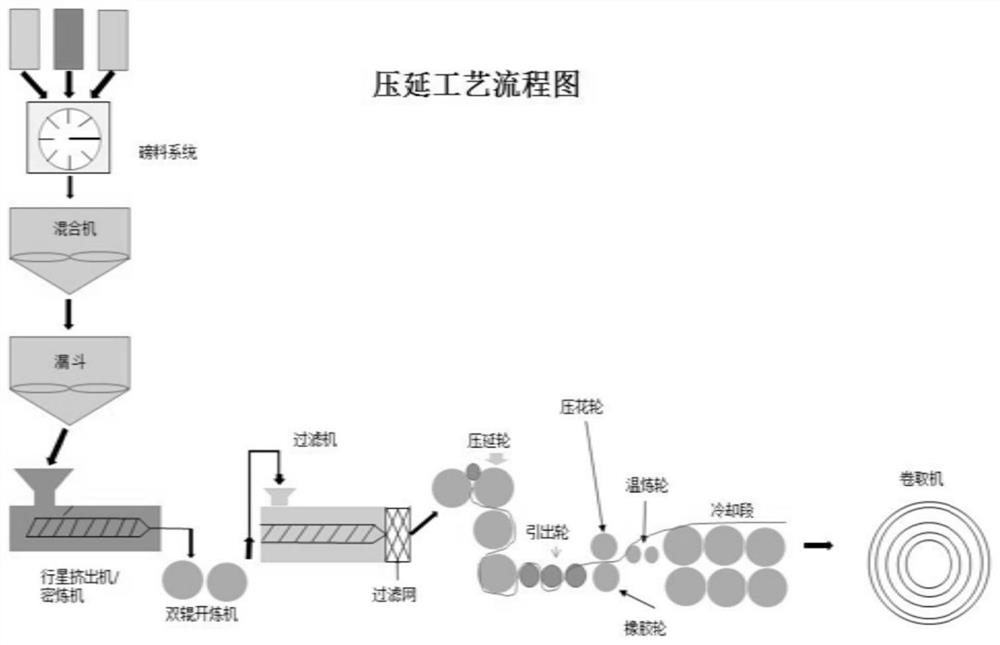

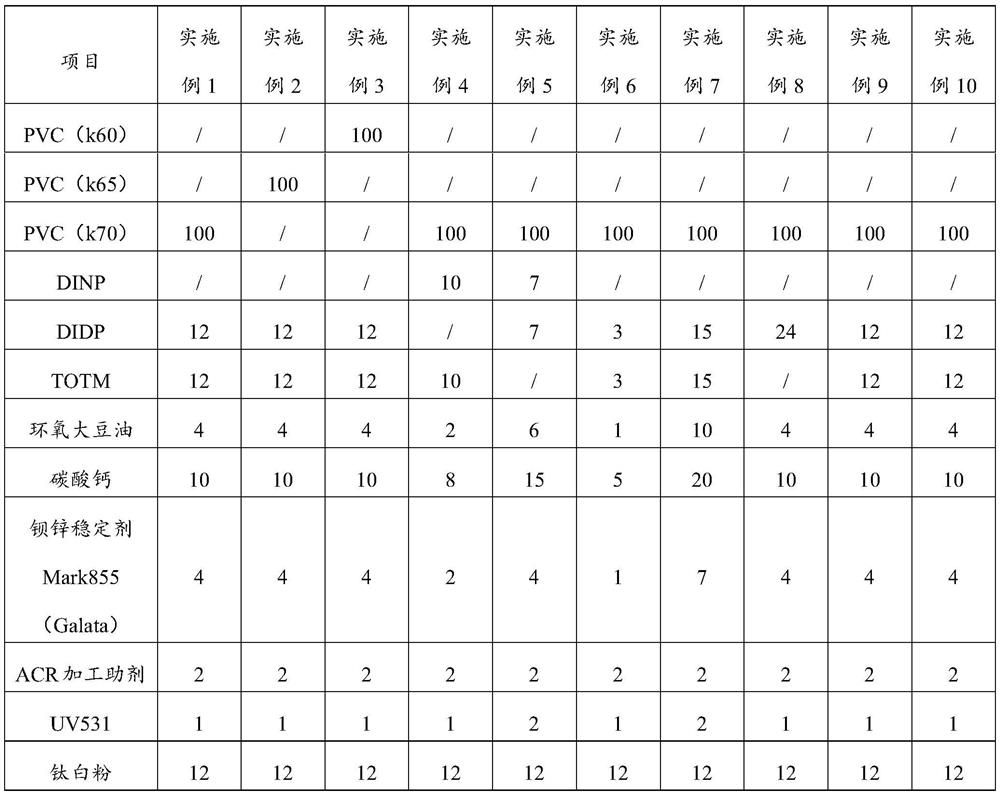

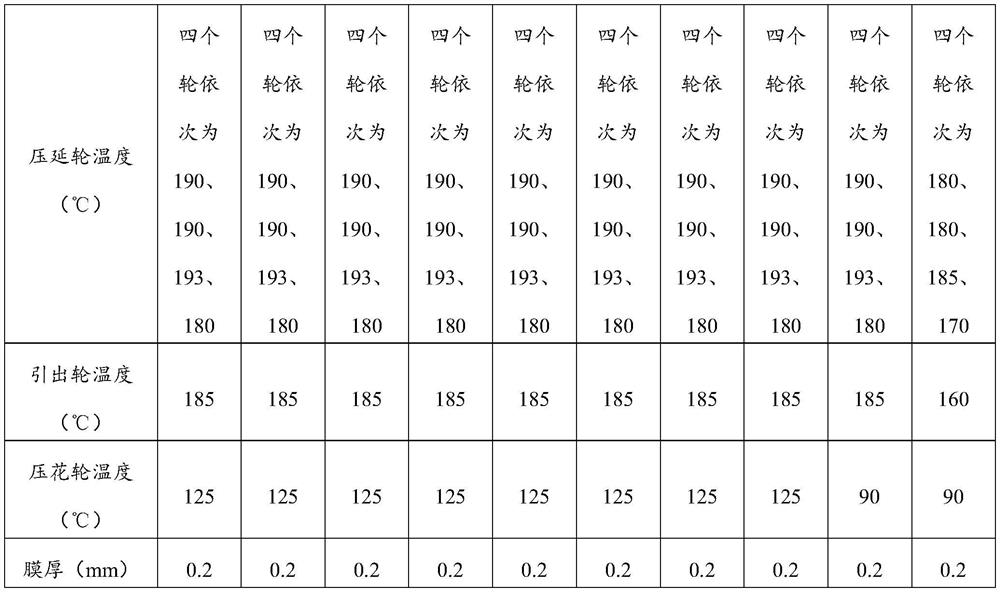

[0018] The embodiment of the high-temperature pattern-stabilized PVC film of the present invention, the formula of the high-temperature pattern-stabilized PVC film described in this embodiment is shown in Table 1, and the preparation method is: put the materials into a mixer and mix them evenly, and then add banburying Mixing in a machine or a planetary machine, then mixing in a double-roller mill, filtering in a filter, and then calendering through a calender wheel, leading out from the pull-out wheel to embossing wheel embossing, cooling, slitting and winding, The high-temperature pattern-stable PVC film was obtained. Wherein, the mixing temperature is 100° C., the temperature of the filter is 150° C., the rotating speed of the calendering wheel is 30 m / min, and the temperature of the cooling wheel is 30° C.

[0019] Table 1 formula list (parts by weight)

[0020]

[0021]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com