Semi-closed tool for forging hollow nuclear power main pipe

A main pipeline, semi-closed technology, used in manufacturing tools, forging/pressing/hammer devices, metal processing equipment, etc., can solve the problem that the section size of hollow steel ingots cannot meet the process deformation and forging ratio, increase the manufacturing cost of pipe fittings, and the manufacturing cycle. Prolonged and other problems, to achieve the effects of huge social and economic benefits, fully forging through grains, and reducing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

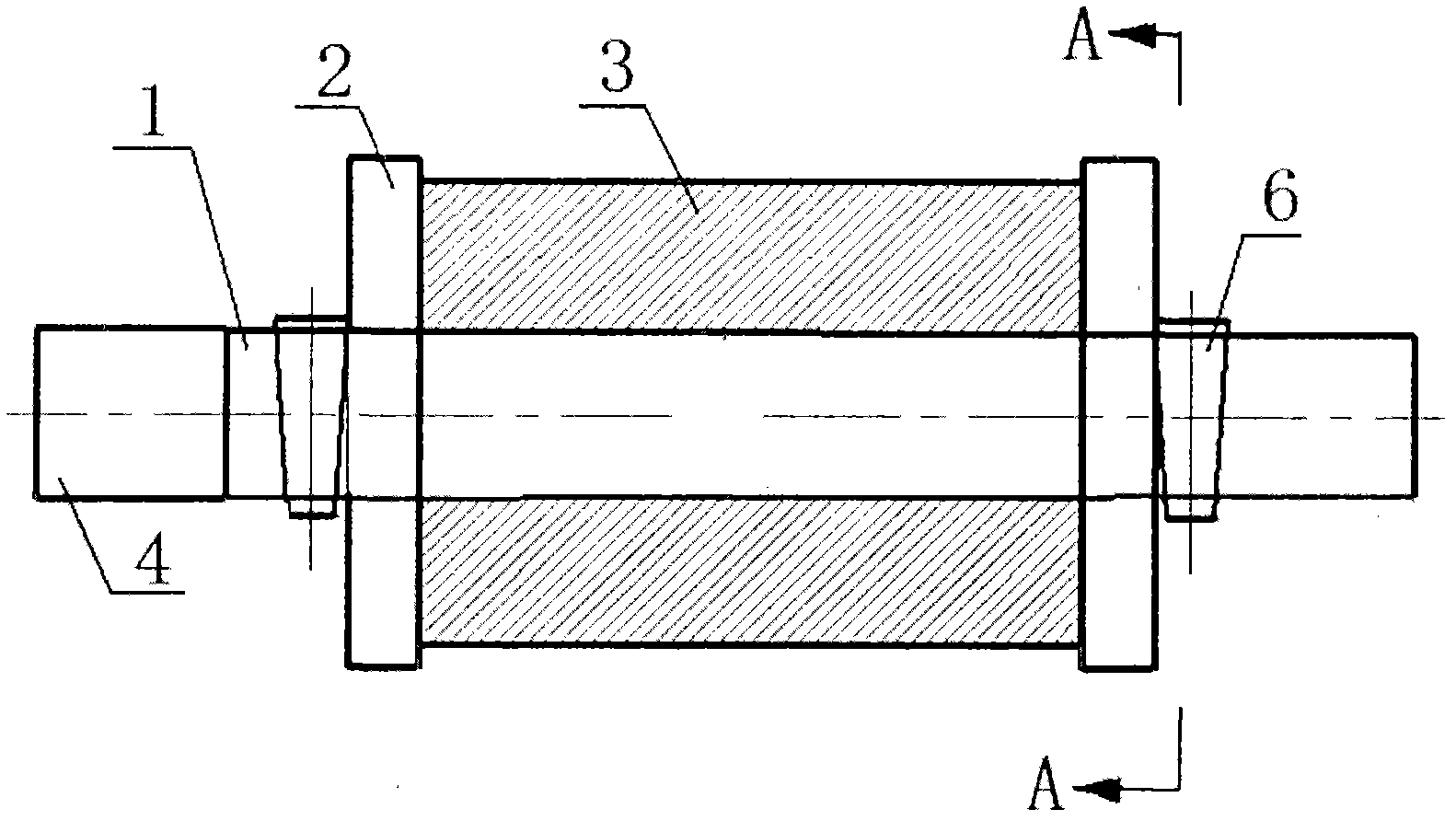

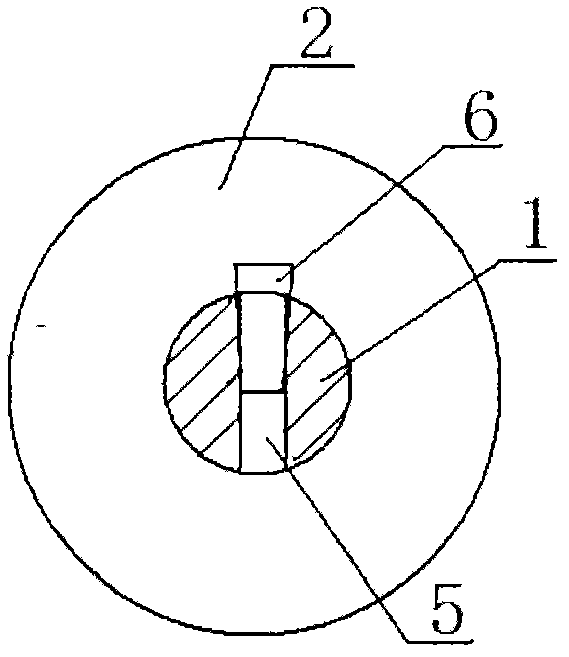

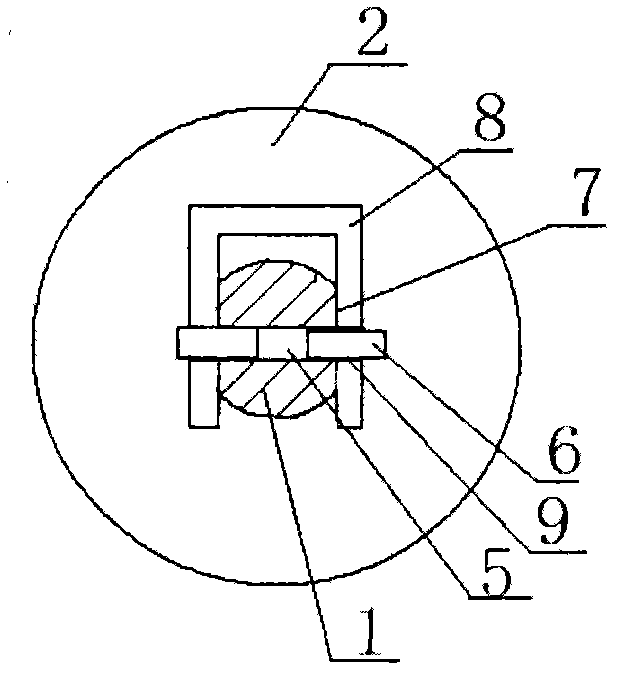

[0016] like figure 1 As shown, the present invention is a semi-closed tooling for forging hollow nuclear power main pipes, the tooling includes a mandrel 1, and two retaining rings 2 are mounted on the mandrel 1, and the two retaining rings 2 are used to forge the nuclear power main pipe 3 Clamped between two retaining rings, a fixed structure for positioning the two retaining rings 2 is installed between the outer sides of the two retaining rings 2 and the mandrel 1, and a prism section can be provided at one end of the mandrel 1 4.

[0017] In the present invention, in order to facilitate the loading and unloading of the hollow nuclear power main pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com