Door-type self-adaptive telescopic hydraulic climbing platform system and climbing method thereof

A self-adaptive, platform technology, applied in the direction of housing structure support, housing structure support, scaffolding supported by housing structure, etc., can solve problems such as damage, deformation of frame structure, and inability to use concrete core tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

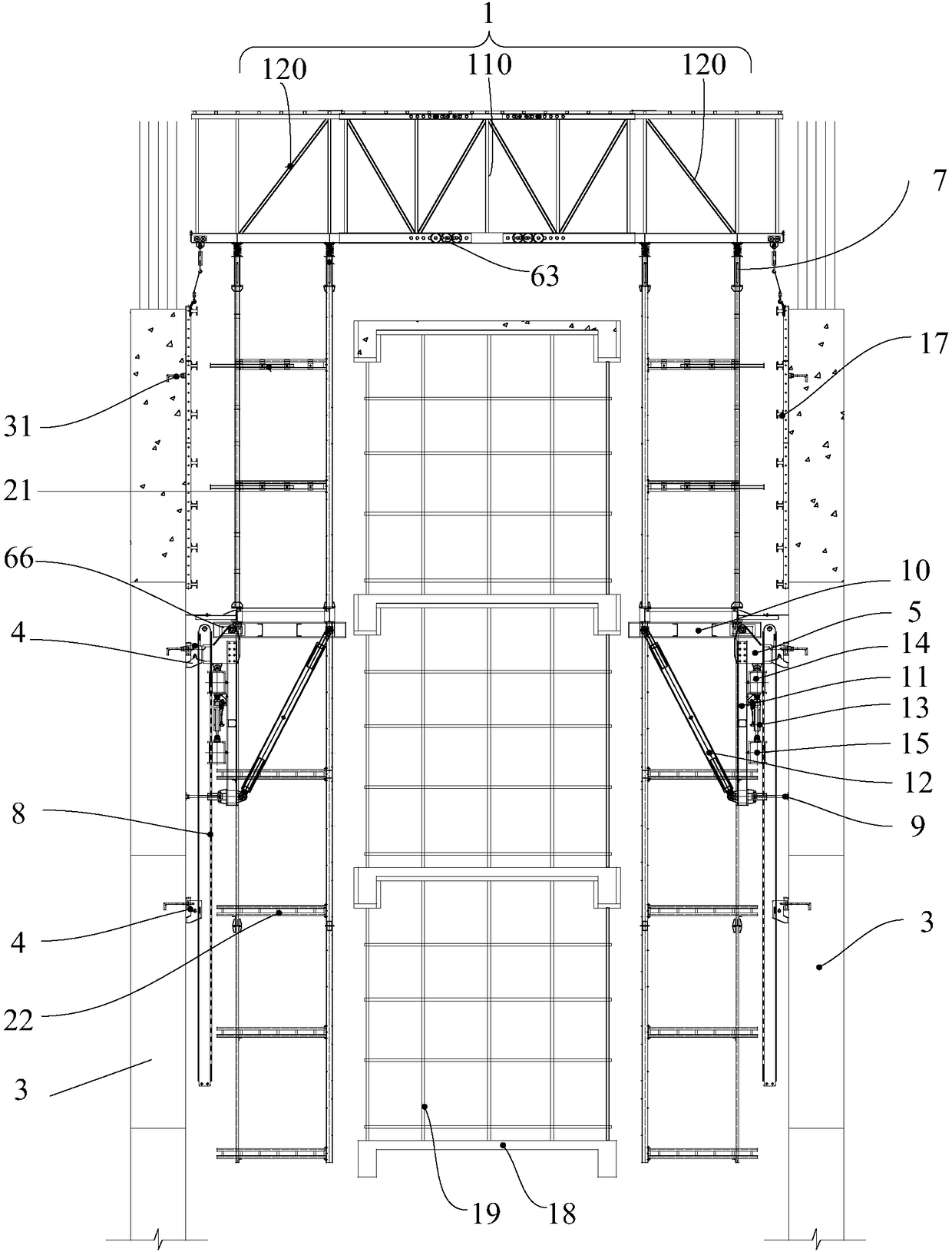

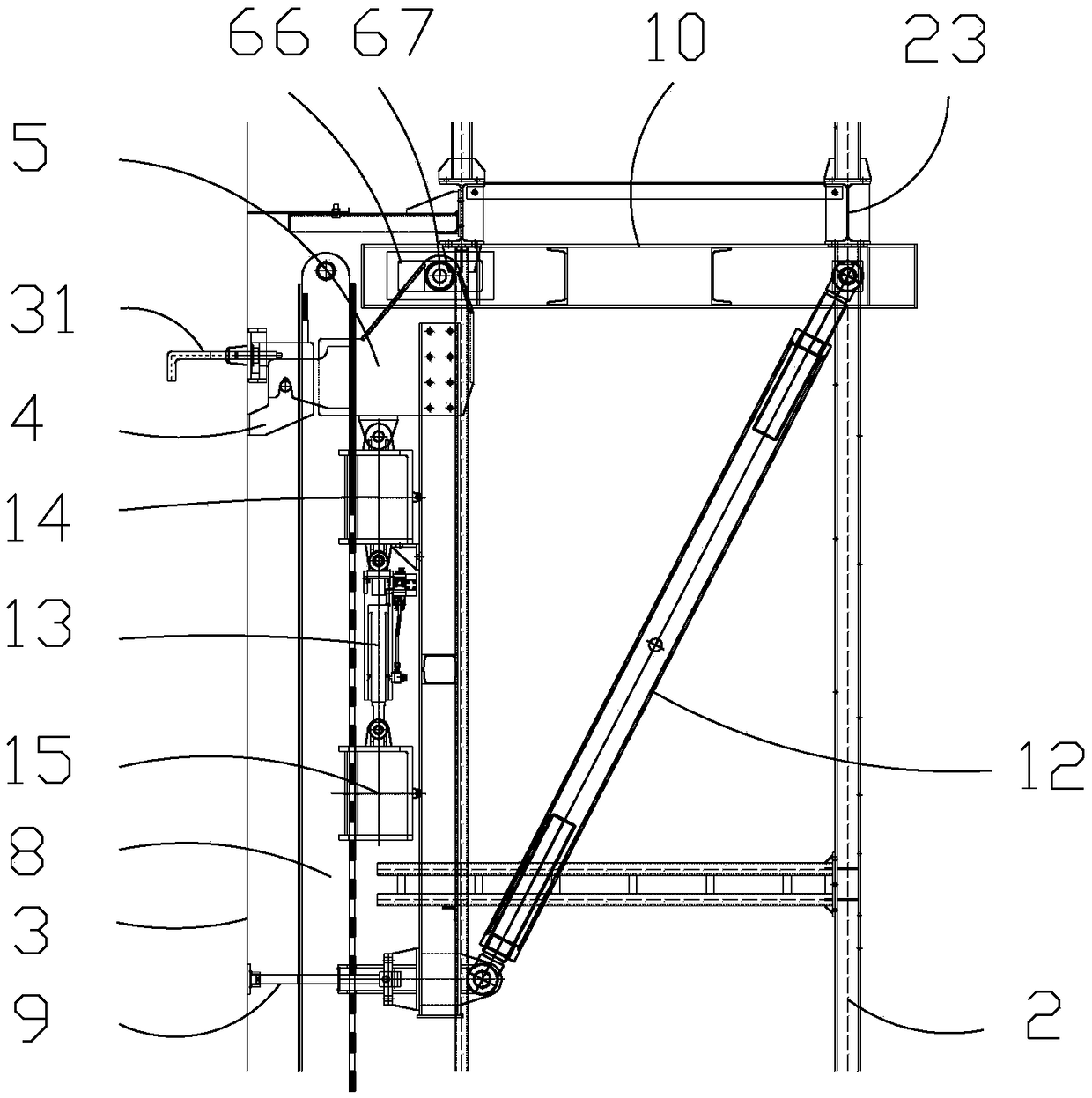

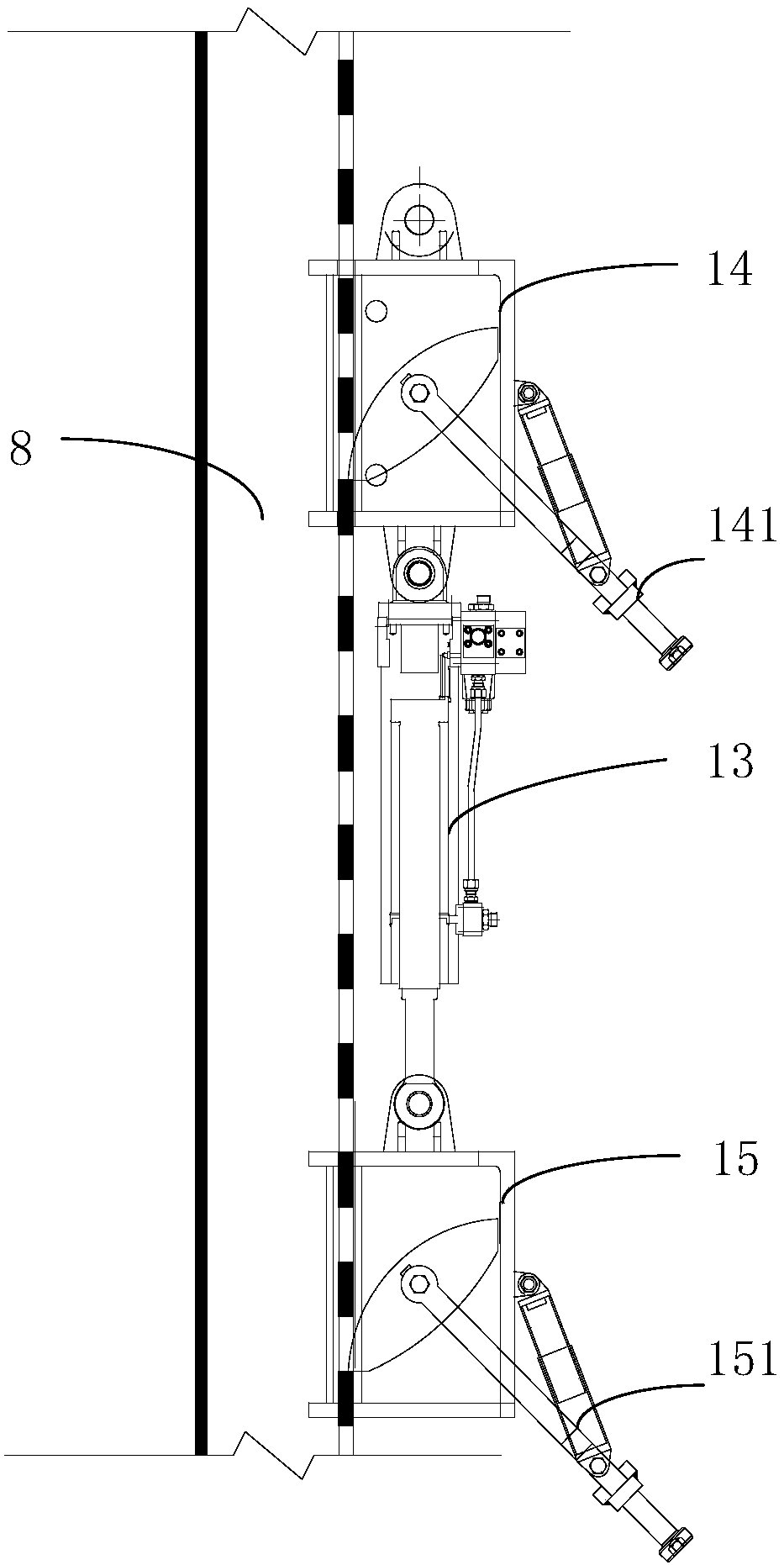

[0076] see Figure 1 to Figure 14 In this embodiment, a portal-type self-adaptive telescopic hydraulic climbing platform system includes a top frame platform 1, two vertical frame bodies 2 and several climbing mechanical systems, and the two vertical frame bodies 2 respectively pass through at least two climbing The mechanical system is relatively arranged on the inner wall of the wall 3 of the core tube. The upper ends of the two vertical frames 2 are respectively connected to the two ends of the top frame platform 1 to form a portal frame. Each climbing mechanical system includes At least three wall attachment devices 4, load-bearing hooks 5 and mechanical climbing devices that are detachably installed on the inner wall of the wall body 3 of the core tube, the load-bearing hooks 5 are respectively connected with the vertical frame body 2 and the mechanical climbing device, the The gantry self-adaptive telescopic hydraulic climbing platform system also includes an adjustment ...

Embodiment 2

[0099] read on Figure 1 to Figure 14 The difference between this embodiment and Embodiment 1 is that the adjustment mechanism only includes a transverse chute 66 arranged on the load-bearing beam 10, and the load-bearing beam 10 includes two double-split channel steels arranged at intervals back to back and connecting two The connector of the double channel steel, the horizontal chute 66 is provided with a movable pin 67, the upper end of the other side of the load-bearing hook 5 is sleeved on the movable pin 67, through the movable pin 67 in the lateral direction The movement in the chute 10 can realize the horizontal movement of the load-bearing hook 5 .

[0100] The climbing method of the portal type self-adaptive telescopic hydraulic climbing platform system of the present embodiment comprises the following steps:

[0101] Step 1, after the concrete pouring of the construction section of the nth floor structure is completed, the steel formwork is removed, and the thickne...

Embodiment 3

[0112] read on Figure 1 to Figure 14 The difference between this embodiment and Embodiment 1 is that the adjustment mechanism also includes a transverse chute 66 arranged on the load-bearing beam 10, and the load-bearing beam 10 includes two double-split channel steels arranged at intervals back to back and connecting two The connector of the double channel steel, the horizontal chute 66 is provided with a movable pin 67, the other side upper end of the load-bearing hook 5 is sleeved on the movable pin 67, through the movable pin 67 in the lateral direction The movement in the chute 66 can realize the horizontal movement of the load-bearing hook 5 .

[0113] The climbing method of the portal type self-adaptive telescopic hydraulic climbing platform system of this embodiment, the method includes the following steps:

[0114] Step 1, after the concrete pouring of the construction section of the nth floor structure is completed, the steel formwork is removed, and the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com