Full-automatic hydraulic prefabricated box girder inner formwork system

A fully automatic, box girder technology, applied in the direction of moulds, ceramic molding cores, ceramic molding mandrels, etc., can solve the problem of internal mold closing, mold opening cannot be carried out synchronously, low reliability and safety, time-consuming and laborious assembly of formwork, etc. problem, to achieve the effect of material saving, comprehensive cost reduction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

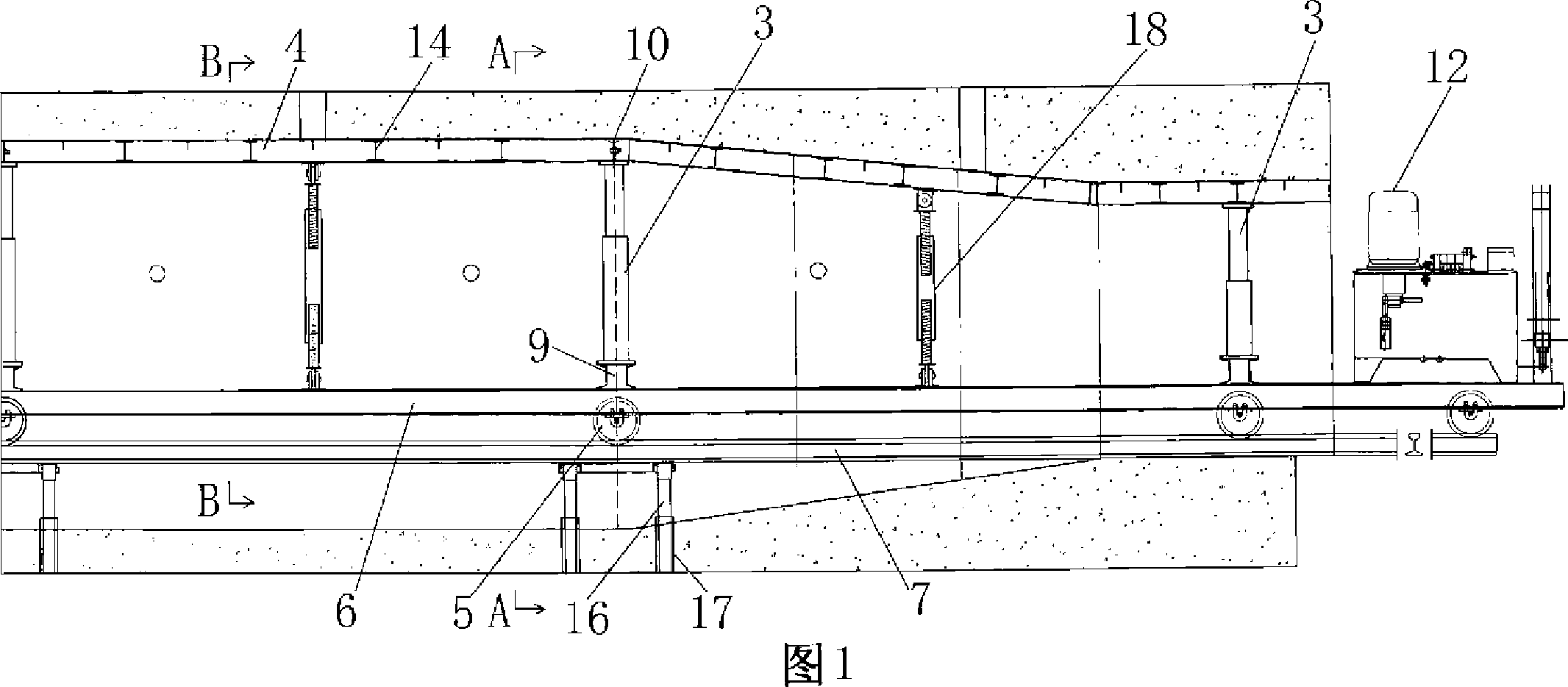

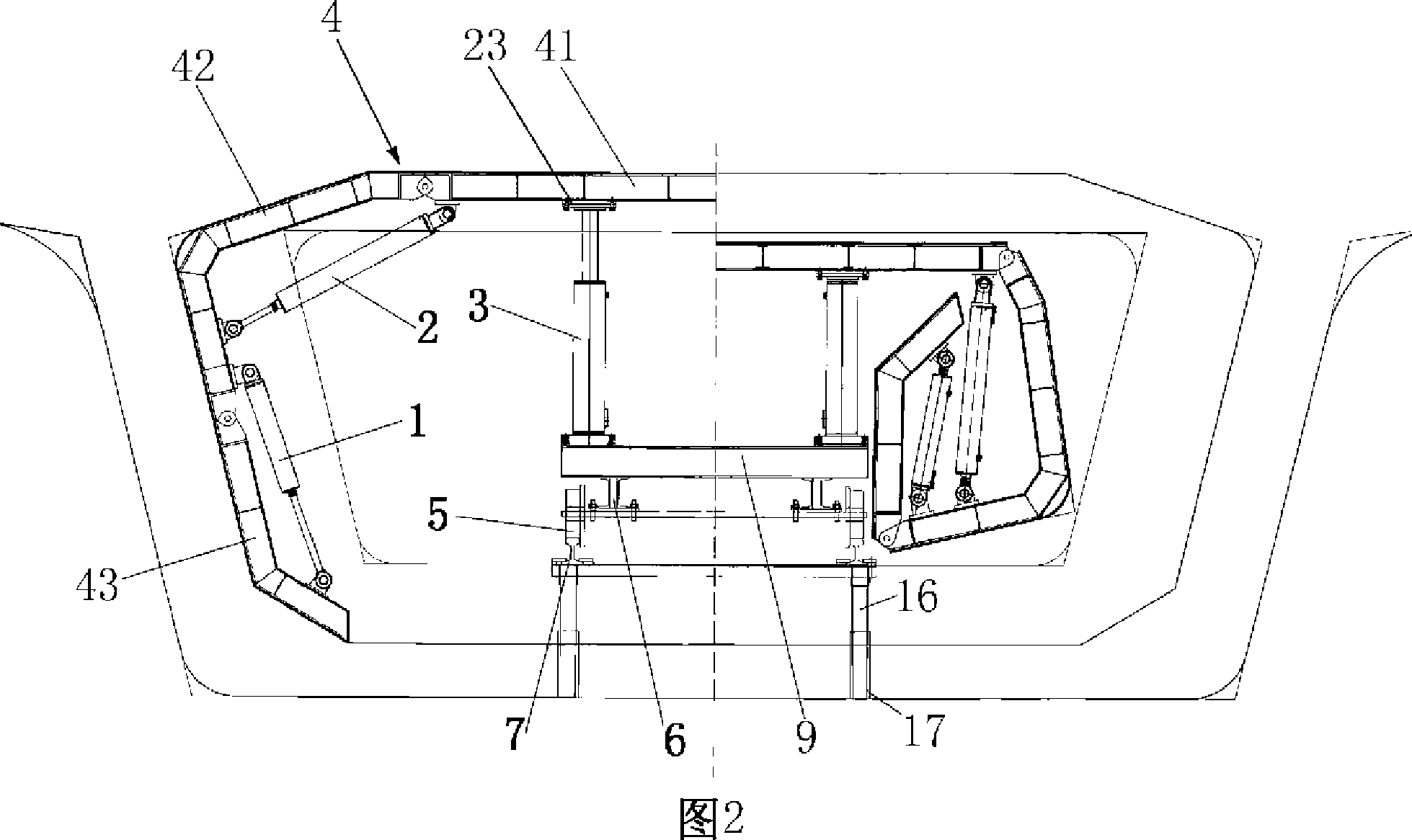

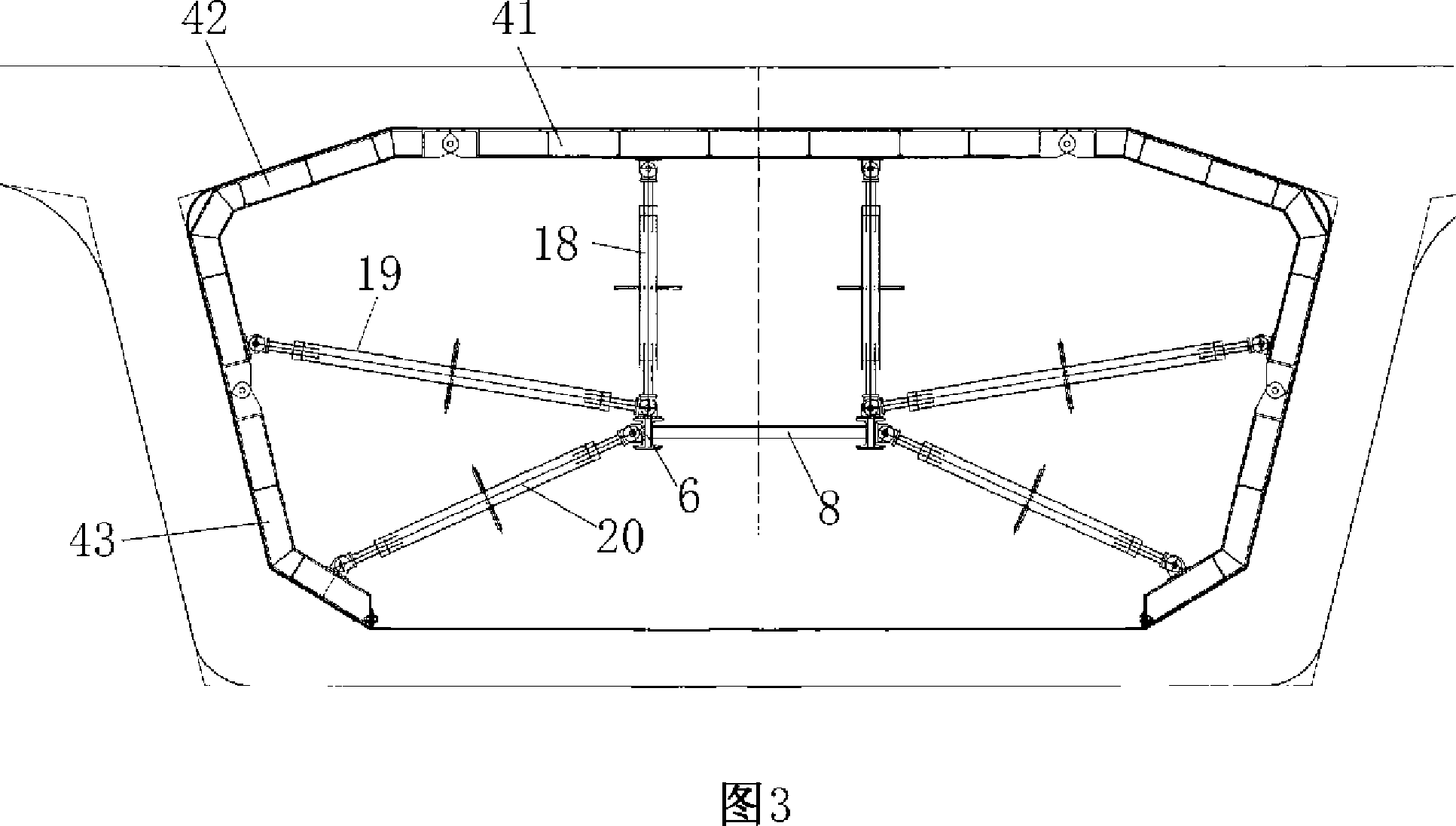

[0035] Referring to Fig. 1-2 for the embodiment, this fully automatic hydraulic prefabricated box girder internal mold system has support frames 16 arranged at intervals along the depth of the box girder in the center of the bottom of the cavity formed by the inner formwork 4, and steel rails 7 are erected on the support frames. Go up the translation trolley, which includes traveling wheels 5, a vehicle frame and a support beam 9 fixed on the vehicle frame, and the frame of the translation trolley extends to the outside of the inner formwork, on which a hydraulic pump station and an operating platform 12 are placed; The frame is mainly composed of two longitudinal beams 6 and a beam 8 connected between the two longitudinal beams.

[0036] Referring to Figure 2, the right side is a schematic diagram of the internal mold shrinking state, and the left side is a schematic diagram of the internal mold expansion state.

[0037] On the jacking section: the upper inclined oil cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com