Building curtain wall decoration automation operation construction device

A technology for construction devices and curtain walls, which is applied to buildings, building components, building structures, etc., can solve the problems of cumbersome installation steps, reduce construction efficiency, etc., and achieve the effects of simple structure, avoidance of danger, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

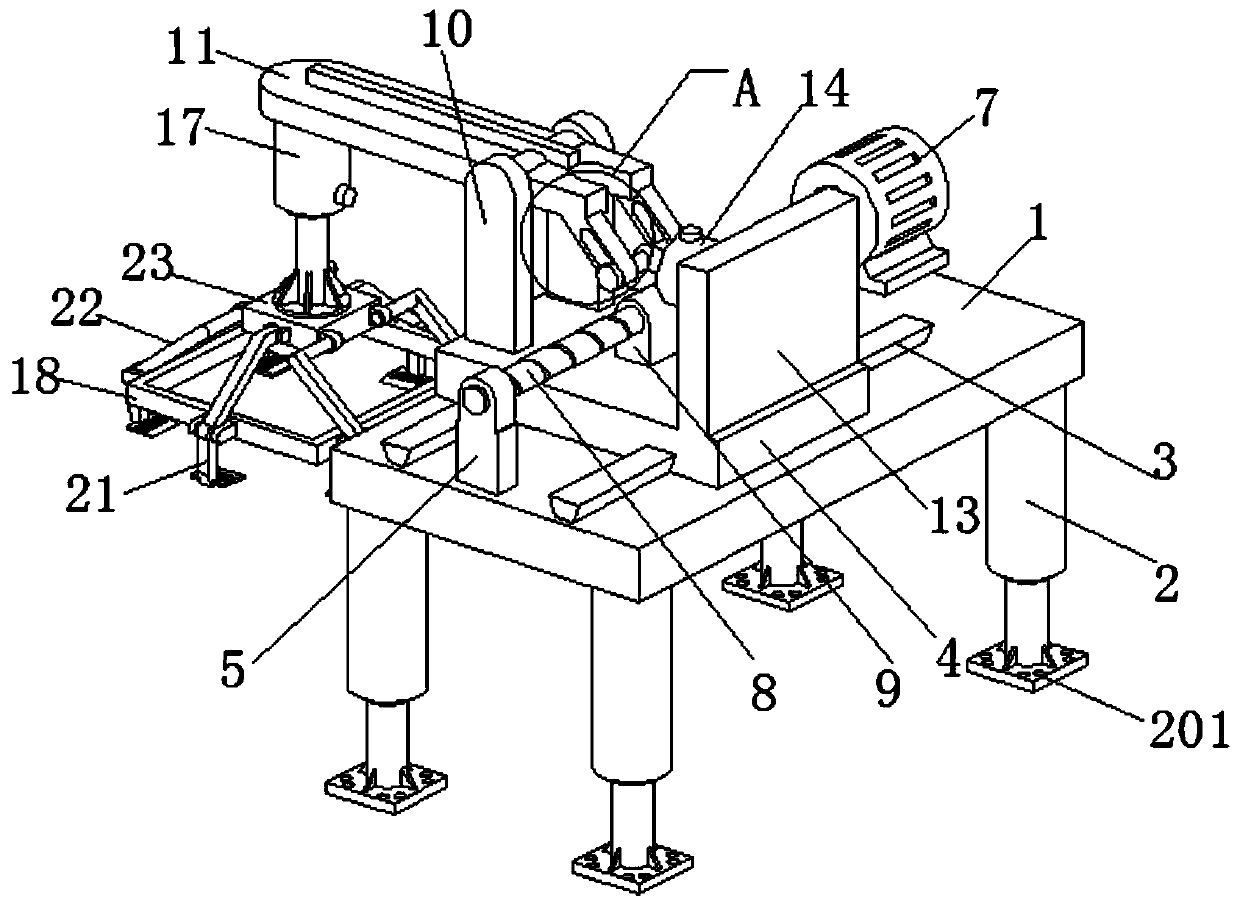

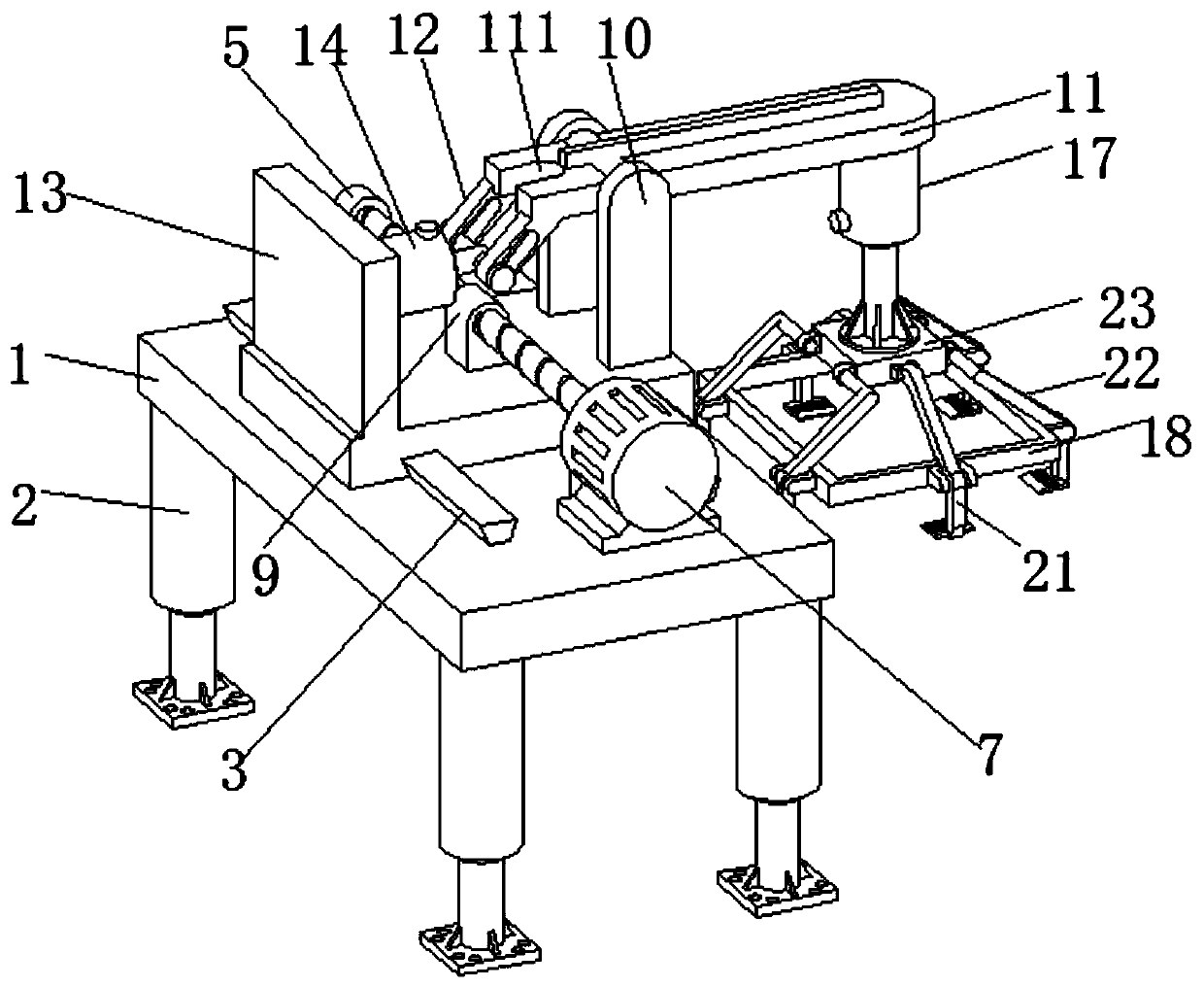

[0036] Embodiment 1 introduces a kind of building curtain wall decoration automatic operation construction device, refer to the attached figure 1 And attached figure 2 , its main structure includes a fixed base 1, a telescopic foot 2, a turning mechanism and a clamping mechanism, and the telescopic foot 2 is fixedly arranged at the four corners of the lower surface of the fixed base 1. Specifically, the telescopic foot 2 can be an electric telescopic rod or a hydraulic One of a kind telescopic pole. The stationary base 1 is provided with a mobile plate 4 .

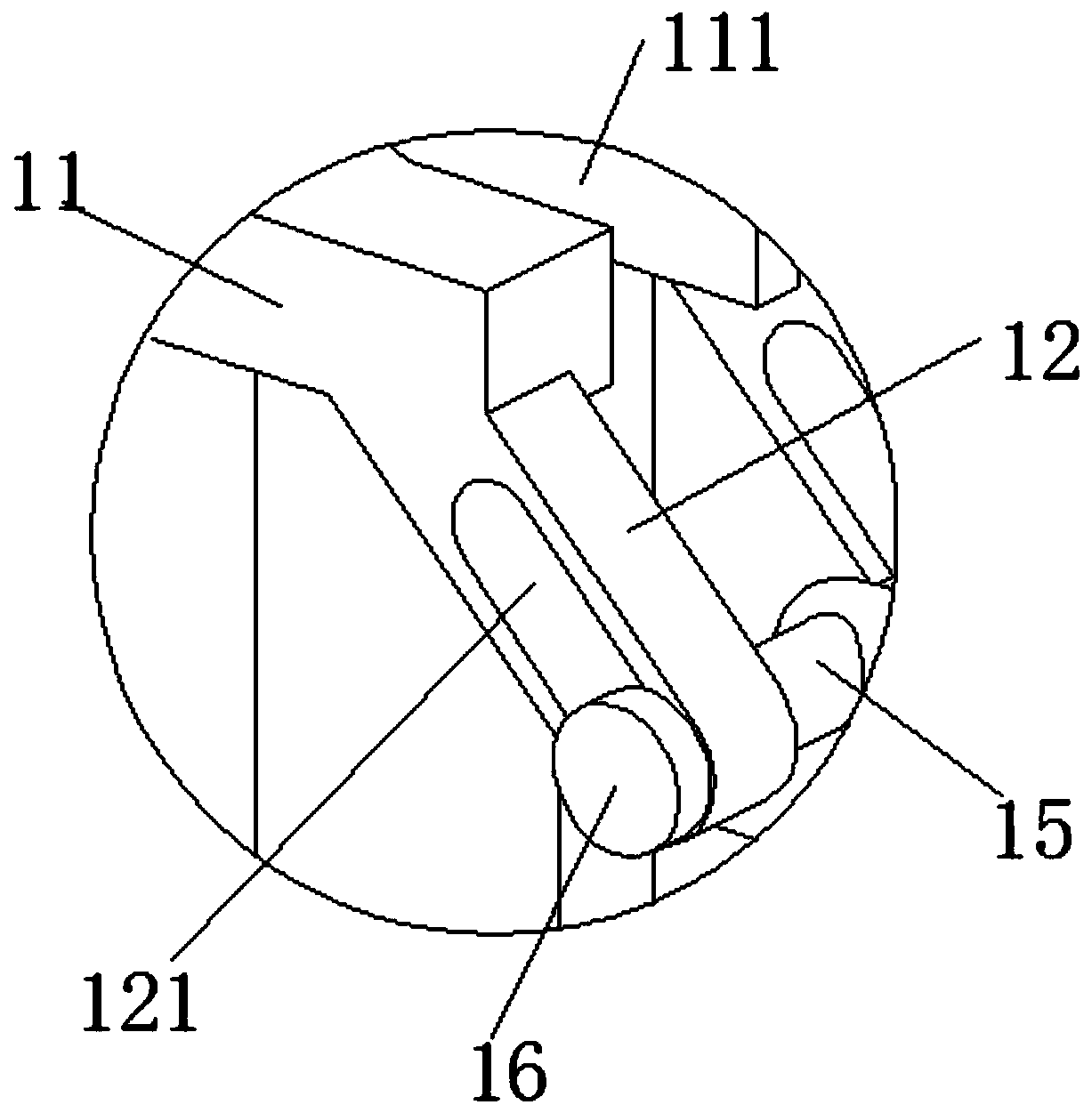

[0037] attached image 3 , attached Figure 4 And attached Figure 5 , the overturning mechanism in the present embodiment comprises that the left end that is arranged on the upper surface of the moving plate 4 is provided with a turret 10, and the turret 10 is rotatably provided with an overturning strip 11. In order to strengthen the intensity of the overturning strip 11, the overturning strip The upper surface of...

Embodiment 2

[0040] Embodiment 2 introduces a kind of building curtain wall decoration automatic operation construction device based on the improvement on embodiment 1, refer to the attached figure 1 And attached figure 2 , its main structure includes a fixed base 1, a telescopic foot 2, a turning mechanism and a clamping mechanism, and the telescopic foot 2 is fixedly arranged at the four corners of the lower surface of the fixed base 1. Specifically, the telescopic foot 2 can be an electric telescopic rod or a hydraulic One of a kind telescopic rod. A moving plate 4 is arranged on the upper surface of the fixed base 1 , and a horizontal pushing mechanism is arranged between the fixed base 1 and the moving plate 4 .

[0041] Specifically, its horizontal pushing mechanism includes that the upper surface of the fixed base 1 is provided with a slide rail 3, the lower surface of the moving plate 4 is provided with a bar-shaped chute 401 matched with the slide rail 3, and the front end of t...

Embodiment 3

[0045] Embodiment 3 introduces a kind of building curtain wall decoration automatic operation construction device based on the improvement on embodiment 2, refer to the attached figure 1 And attached figure 2 , its main structure includes a fixed base 1, a telescopic foot 2, a turning mechanism and a clamping mechanism, and the telescopic foot 2 is fixedly arranged at the four corners of the lower surface of the fixed base 1. Specifically, the telescopic foot 2 can be an electric telescopic rod or a hydraulic One of the telescopic rods, and the lower end of the telescopic leg 2 is provided with a fixing device 1 . A moving plate 4 is arranged on the upper surface of the fixed base 1 , and a horizontal pushing mechanism is arranged between the fixed base 1 and the moving plate 4 .

[0046] Specifically, its horizontal pushing mechanism includes that the upper surface of the fixed base 1 is provided with a slide rail 3, the lower surface of the moving plate 4 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com