Borehole and counterbore machine for annular mold

A technology of countersinking and ring die, applied in drilling/drilling equipment, boring/drilling, boring machine/drilling machine parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

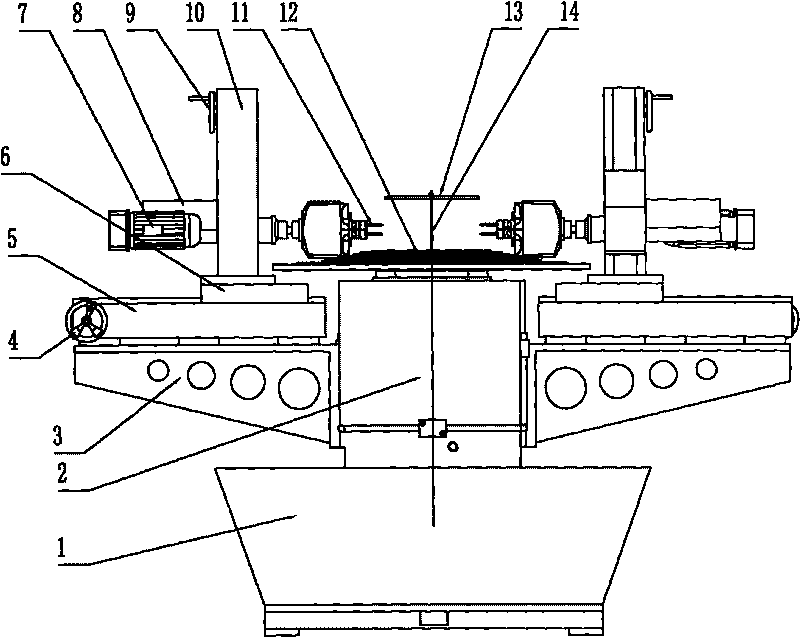

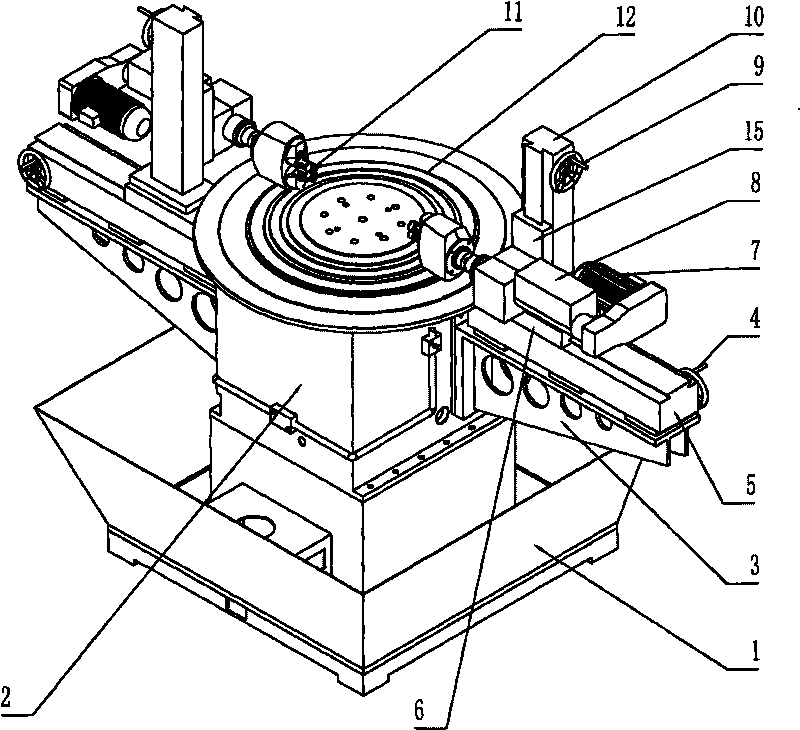

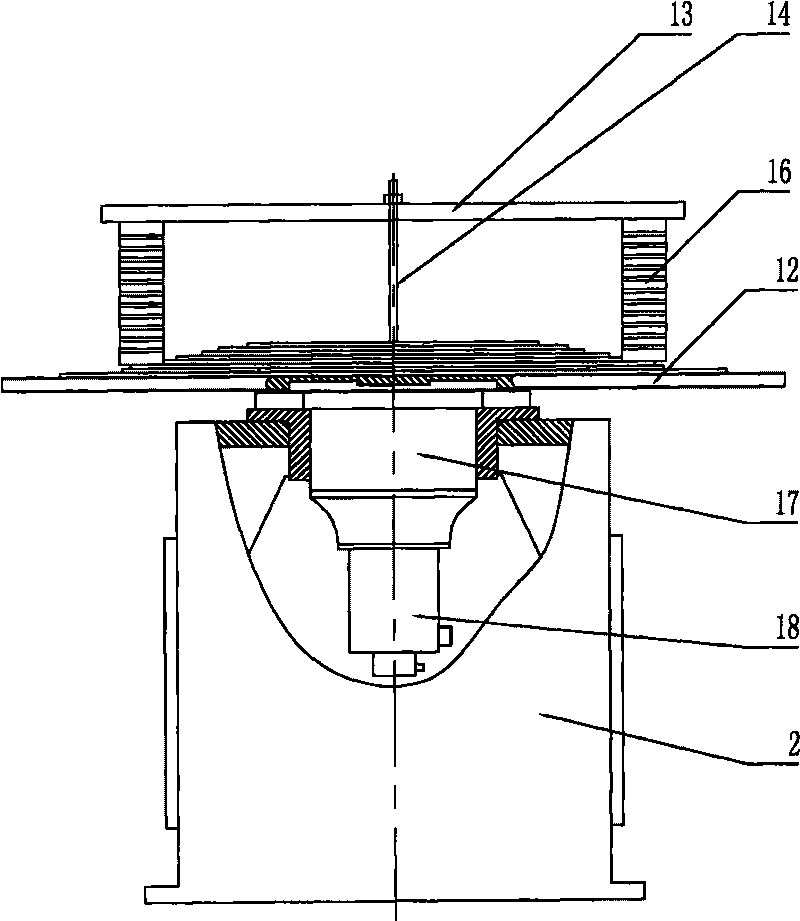

[0017] As shown in the figure, it is a ring die drilling and sinking machine, which includes a main shaft housing 2, the main shaft housing 2 is arranged in the cutting oil tank 1, and supporting beams 3 are respectively arranged on both sides of the main shaft housing 2, and each supporting beam 3 There is a horizontal guide rail 5 on the top, and a horizontal slider 6 is arranged on the horizontal guide rail 5, and the horizontal slider 6 and the horizontal guide rail 5 are connected through a screw nut pair of transmission; the vertical guide rail 9 is vertically fixed on the horizontal slider 6, vertical The guide rail 9 is equipped with a vertical slider 15, and the vertical slider 15 and the vertical guide rail 9 are connected through another screw nut pair transmission, and the above screw nut transmission pairs are all driven by the hand wheels 4 and 9, so that the corresponding sliders Move; drill bit assembly is fixed on the vertical slide block 15, and this drill bit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com