Automatic mark making system and method for cotton bale

A cotton bale and automatic technology, which is applied in packaging and other directions, can solve the problems that it is difficult to adapt to the requirements of cotton processing technology and technology, the information of cotton bales is unclear, and the labor intensity is high, so as to achieve convenient work and inspection, low cost, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

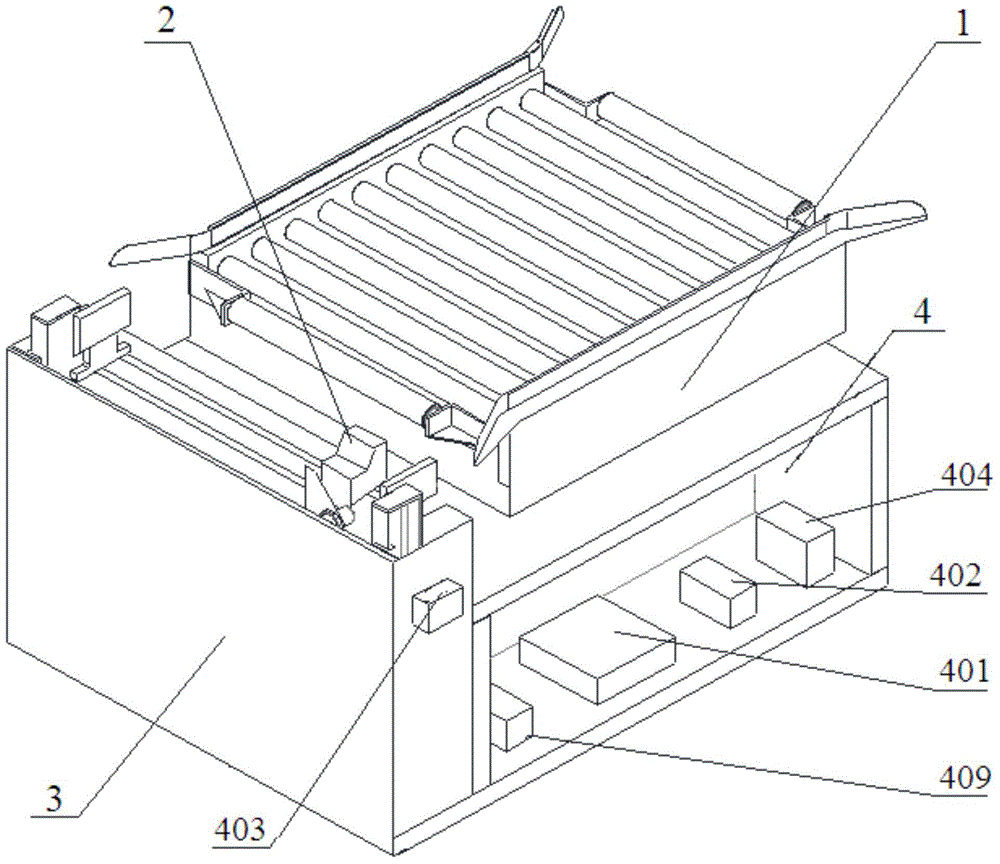

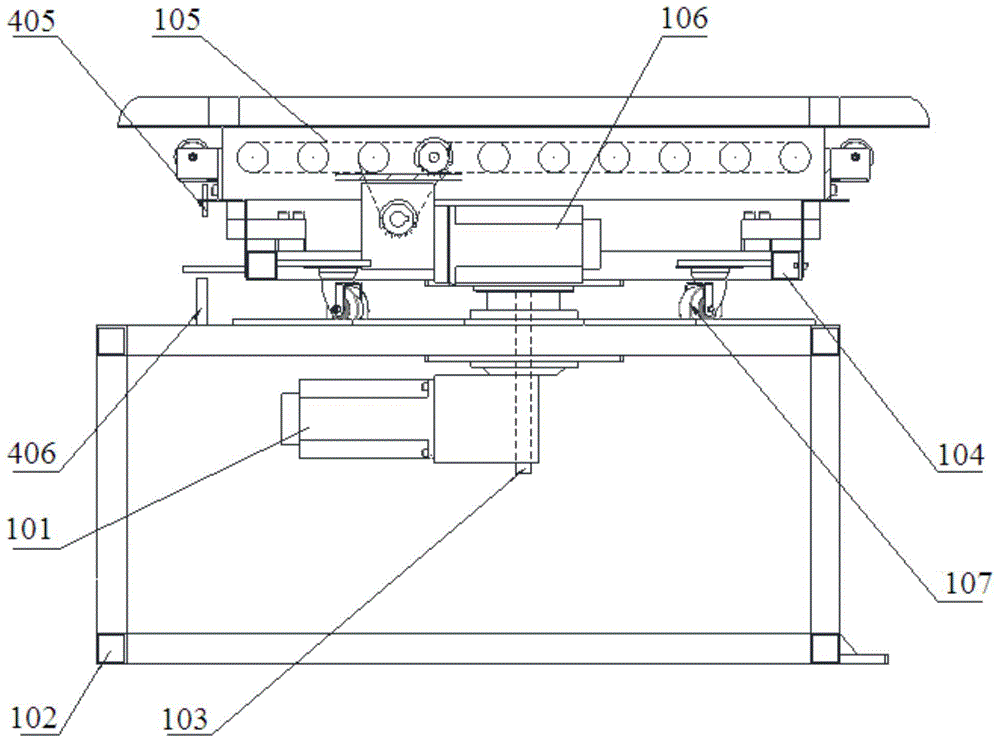

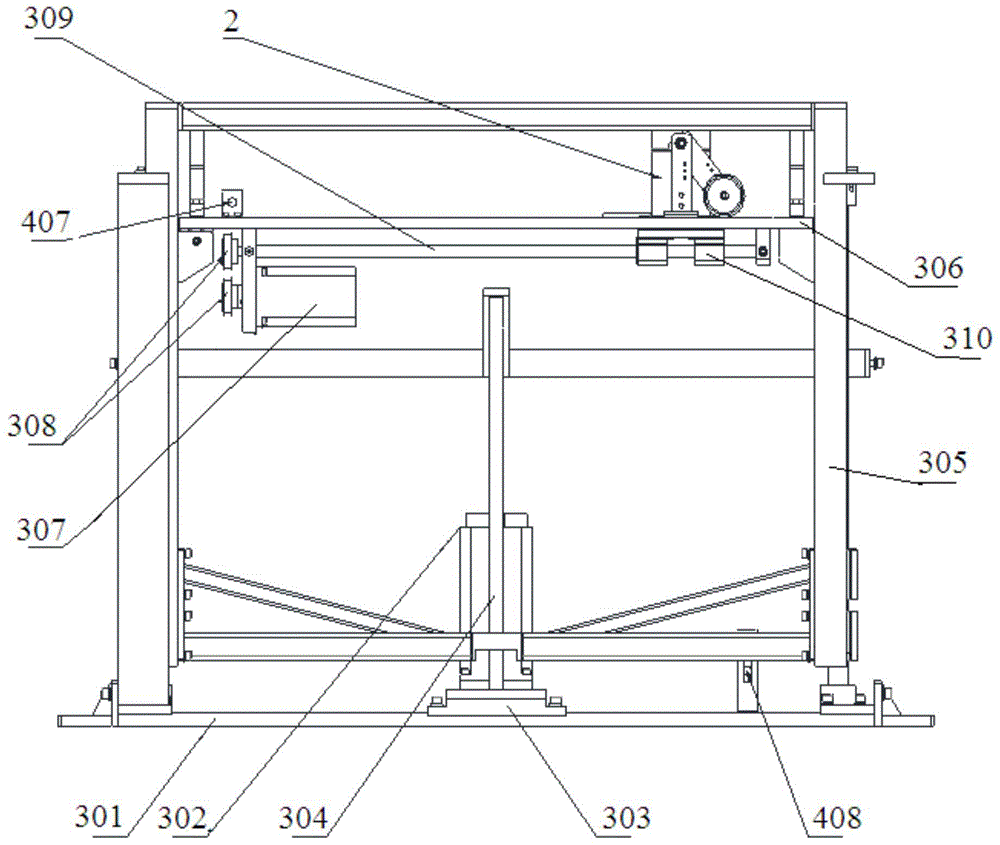

[0021] Such as figure 1 As shown, the cotton bale automatic swabbing system provided in this embodiment includes a subcontracting platform 1, a swabbing nozzle 2, a submerged swabbing nozzle driving device 3 and an automatic control device. The brush-mark nozzle 2 is arranged on the submerged brush-mark nozzle driving device 3 , and the submerged brush-mark nozzle driving device 3 is arranged on one side of the subcontracting platform 1 . After the subcontracting platform 1 transports one end of the cotton bale to the brush mark position, the automatic control device starts the brush mark nozzle 2 and the submerged brush mark nozzle drive device 3, and the sink type brush mark nozzle drive device 3 drives the brush mark nozzle 2 to vertically lift And move horizontally to print the required cotton bale information to the end of the cotton bale on the sub-bale platform 1. When one end of the cotton bale is finished marking, the automatic control device controls the marking noz...

Embodiment 2

[0031] The automatic swabbing system for cotton bales provided in this embodiment has basically the same structure as that of the first embodiment, the difference being that: both sides of the subcontracting platform 1 are provided with swabbing nozzles 2 and submerged swabbing nozzle driving devices 3 . After the subcontracting platform 1 transports the cotton bales to the brushing position, the automatic control device starts the brushing nozzles 2 on both sides and the submerged brushing nozzle driving device 3, and the sinking brushing nozzle driving device 3 on both sides drives the brushing nozzles 2 Simultaneously vertically lift and move horizontally to simultaneously print the required cotton bale information on both ends of the cotton bale on the sub-bale platform 1.

[0032] Such as Figure 4 As shown, based on the cotton bale automatic swabbing system provided in the above-mentioned embodiments, the present invention also proposes a cotton bale automatic swabbing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com