Method for rapidly detecting surface formation defect of thin sheet

A surface forming and thin plate technology, applied in the direction of measuring devices, instruments, mechanical devices, etc., to achieve the effect of simple measurement method, high accuracy and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

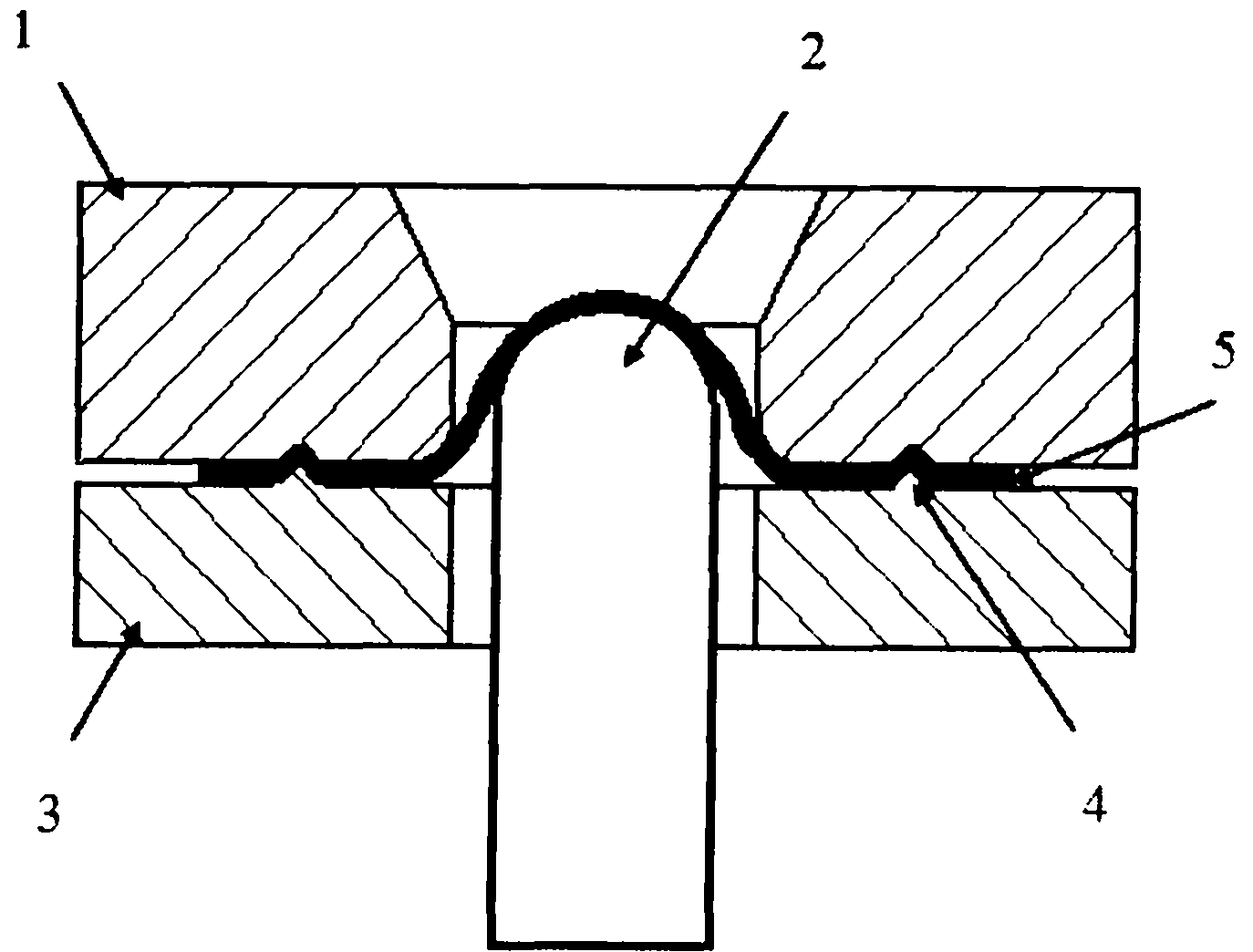

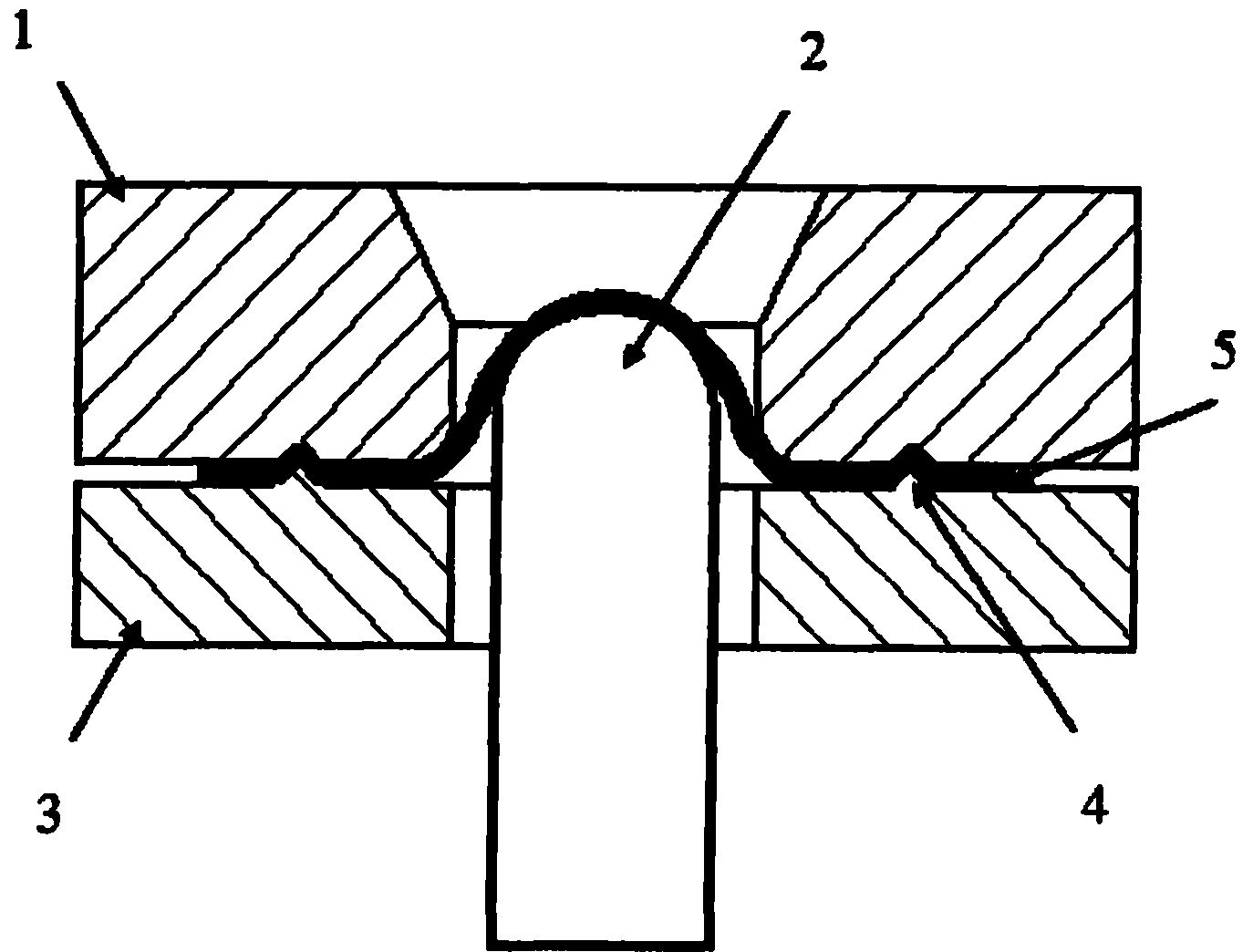

Method used

Image

Examples

Embodiment 1

[0020] Example 1: The bulging height is 2mm, and the maximum strain on the bulging surface is about 0.2%. The cause of the slip line is the existence of the yield platform of the thin plate. The shifting line begins to appear, and the appearance of slipping line is a substandard product;

Embodiment 2

[0021] Example 2: The bulging height is 5mm, and the maximum strain on the bulging surface is about 1%. The cause of the slip line is the existence of the yield platform of the thin plate. The yield platform is most obvious when the strain is 1%, so the height It is the best height to detect the slip line, if there is a slip line, it is a substandard product;

Embodiment 3

[0022] Example 3: The bulging height is 10mm, and the maximum strain on the bulging surface is about 5%. At this time, because the strain of the board surface has passed the yield stage, the slip line defect will become less and less obvious, and the board surface will Orange peel defects begin to appear, and orange peel defects appear as unqualified products;

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com