Photosensitive resin composition, black array, color filter and liquid crystal display element thereof

一种感光性树脂、组成物的技术,应用在感光性树脂组成物领域,能够解决感光性低、表面阻抗稳定性不佳、黑色矩阵表面平坦性损失等问题,达到佳表面阻抗稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

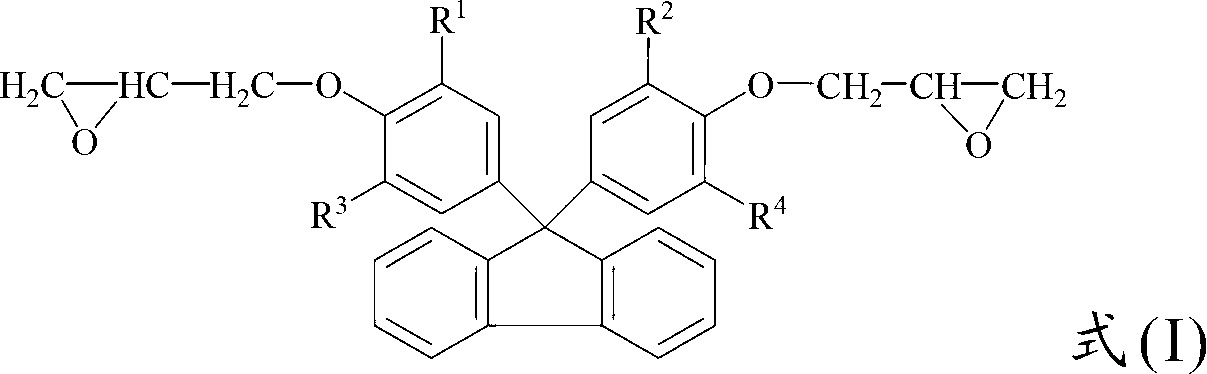

[0148] With 100 parts by weight of fluorene epoxy compound (model ESF-300, manufactured by Nippon Steel Chemical; epoxy equivalent 231), 30 parts by weight of acrylic acid, 0.3 parts by weight of benzyltriethylammonium chloride, 0.1 parts by weight of 2,6-di-tert-butyl-p-cresol, and 130 parts by weight of propylene glycol monomethyl ether acetate are added to a 500mL four-necked flask in a continuous addition mode, and the feed rate is controlled at 25 parts by weight / minute, The temperature in the reaction process is maintained at 100° C. to 110° C., and after 15 hours of reaction, a light yellow transparent mixed liquid with a solid content concentration of 50 wt % can be obtained.

[0149] Then, 100 parts by weight of the above-mentioned light yellow transparent mixed solution was dissolved in 25 parts by weight of ethylene glycol monoethyl ether acetate, and 6 parts by weight of tetrahydrophthalic anhydride and 13 parts by weight of tetrahydrophthalic anhydride were added a...

Synthetic example 2

[0151] With 100 parts by weight of fluorene epoxy compound (model ESF-300, manufactured by Nippon Steel Chemical; epoxy equivalent 231), 30 parts by weight of acrylic acid, 0.3 parts by weight of benzyltriethylammonium chloride, 0.1 parts by weight of 2,6-di-tert-butyl-p-cresol, and 130 parts by weight of propylene glycol monomethyl ether acetate are added in a 500mL four-necked flask in a continuous addition mode, and the feed rate is controlled at 25 parts by weight / minute, The temperature in the reaction process is maintained at 100° C. to 110° C., and after 15 hours of reaction, a light yellow transparent mixed liquid with a solid content concentration of 50 wt % can be obtained.

[0152] Next, 100 parts by weight of the light yellow transparent mixed solution obtained above was dissolved in 25 parts by weight of ethylene glycol monoethyl ether acetate, and 13 parts by weight of benzophenone tetracarboxylic dianhydride was added, and the mixture was heated at 90° C. React ...

Synthetic example 3

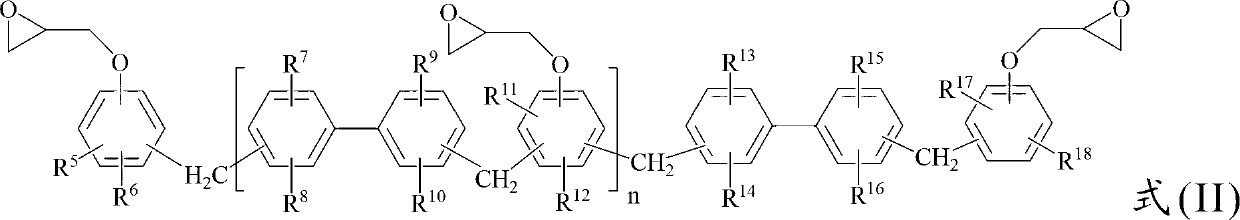

[0154] 400 parts by weight of epoxy compound [model NC-3000, produced by Nippon Kayaku (Co., Ltd.); epoxy equivalent 288], 102 parts by weight of acrylic acid, 0.3 parts by weight of p-methoxyphenol (p-methoxyphenol), 5 parts by weight The triphenylphosphine of weight part, and the propylene glycol monomethyl ether acetate of 264 weight parts are placed in reaction bottle, and the temperature of this reaction process is maintained on 95 ℃, reacts 9 hours, can obtain an acid value and be 2.2mgKOH / intermediate product of g. Next, 151 parts by weight of tetrahydrophthalic anhydride (tetrahydrophthalic anhydride) was added and reacted at 95°C for 4 hours to obtain an unsaturated compound with an acid value of 102 mgKOH / g and a weight average molecular weight of 3,200. Resin (hereinafter abbreviated as A-1-3).

[0155] [Preparation of other alkali-soluble resins (A-2)]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com