Photosensitive resin composition, black matrix, color filter and liquid crystal display element thereof

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition, can solve problems such as poor surface resistance stability, and achieve the effect of good surface resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0136] The preparation method of the black pigment dispersion (F) can adopt the general mixing method, for example, the black pigment component (F-1) coated with the resin, the dispersant (F-2) and the second solvent (F- 3) Mix and add media such as glass beads, zirconia beads, etc., and then pass through paint conditioner, ball mill, sand grinder, Mixing is performed by twin-roll, three-roll, homogenizer system, jet mill or ultrasonic waves.

[0137] The average particle diameter of the resin-coated black pigment component (F-1) in the black pigment dispersion (F) was obtained with a known particle size analyzer of the laser doppler type, and the black The average particle diameter of the resin-coated black pigment component (F-1) in the pigment dispersion (F) ranges from 80 nm to 300 nm. Preferably, the average particle size of the resin-coated black pigment component (F-1) in the black pigment dispersion (F) ranges from 80 nm to 200 nm. When the average particle size of t...

Synthetic example 1

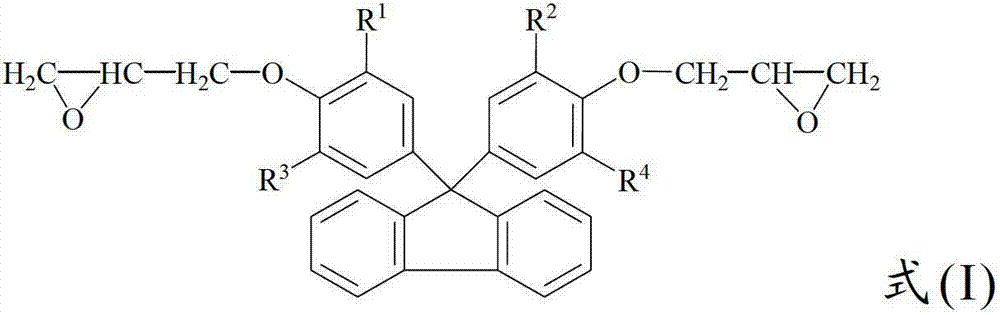

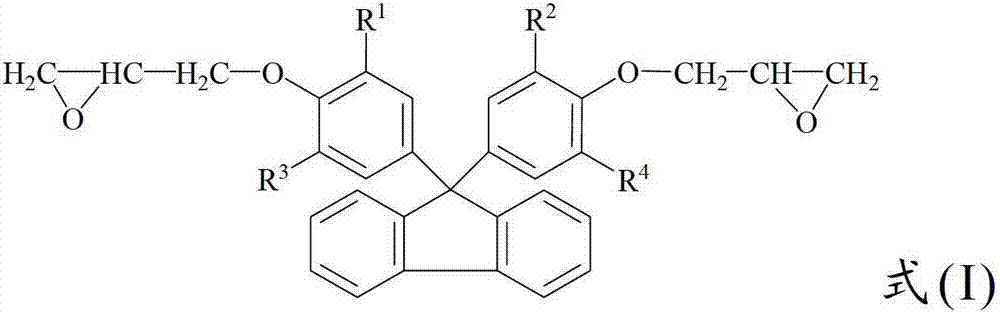

[0206] With 100 parts by weight of fluorene epoxy compound (model ESF-300, manufactured by Nippon Steel Chemical; epoxy equivalent 231), 30 parts by weight of acrylic acid, 0.3 parts by weight of benzyltriethylammonium chloride, 0.1 parts by weight of 2,6-di-tert-butyl-p-cresol, and 130 parts by weight of propylene glycol monomethyl ether acetate are added to a 500mL four-necked flask in a continuous addition mode, and the feed rate is controlled at 25 parts by weight / minute, The temperature in the reaction process is maintained at 100° C. to 110° C., and after 15 hours of reaction, a light yellow transparent mixed liquid with a solid content concentration of 50% by weight can be obtained.

[0207] Then, 100 parts by weight of the above-mentioned light yellow transparent mixed solution was dissolved in 25 parts by weight of ethylene glycol monoethyl ether acetate, and 6 parts by weight of tetrahydrophthalic anhydride and 13 parts by weight of tetrahydrophthalic anhydride were a...

Synthetic example 2

[0209] With 100 parts by weight of fluorene epoxy compound (model ESF-300, manufactured by Nippon Steel Chemical; epoxy equivalent 231), 30 parts by weight of acrylic acid, 0.3 parts by weight of benzyltriethylammonium chloride, 0.1 parts by weight of 2,6-di-tert-butyl-p-cresol, and 130 parts by weight of propylene glycol monomethyl ether acetate are added to a 500mL four-necked flask in a continuous addition mode, and the feed rate is controlled at 25 parts by weight / minute, The temperature in the reaction process is maintained at 100° C. to 110° C., and after 15 hours of reaction, a light yellow transparent mixed liquid with a solid content concentration of 50% by weight can be obtained.

[0210] Next, 100 parts by weight of the light yellow transparent mixed solution obtained above was dissolved in 25 parts by weight of ethylene glycol monoethyl ether acetate, and 13 parts by weight of benzophenone tetracarboxylic dianhydride was added, and the mixture was heated at 90° C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface impedance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com