Method of making plastic section bar for door and window by glass fiber reinforced thermoplastic composite material

A technology to enhance thermoplasticity and thermoplastics, applied in the direction of wing leaf frame, etc., can solve the problems of restricting the development of building door and window industry, the failure of FRP door and window profiles to be recycled, and increasing the cost of FRP door and window, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

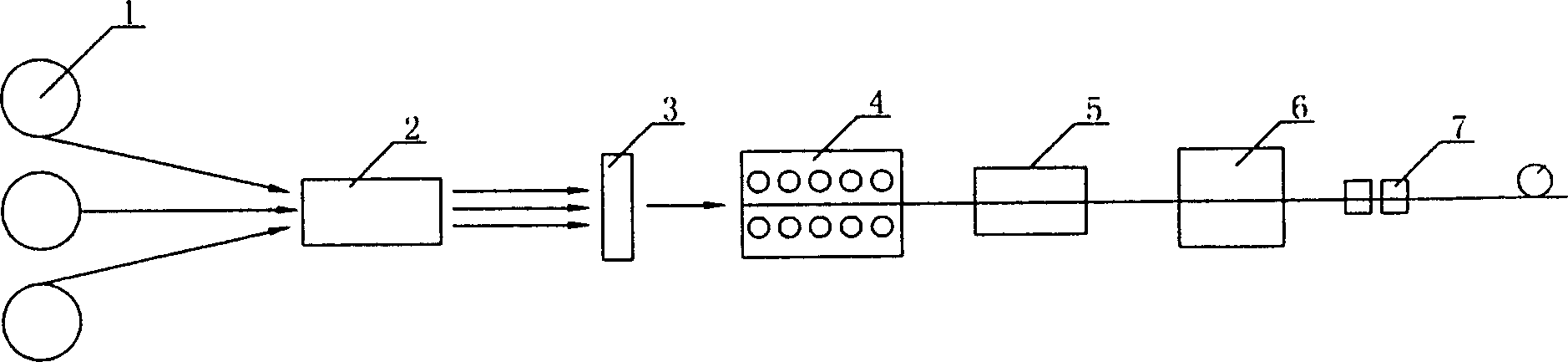

[0007] As shown in the accompanying drawing, the glass fiber and its fabric on the creel (1) advance under the action of the tractor (7), absorb the thermoplastic resin polymer powder in the powder fluidized bed (2), and mix with the molten thermoplastic The resin forms the prepreg fibers. The prepreg fibers are bundled after passing through the cluster plate (3), and then the resin matrix in the prepreg fiber bundles is heated to a viscous flow state at 200°C to 240°C by the heating box (4). Under the action of traction, the molten prepreg The fiber enters the molding die (5) for pultrusion molding to obtain elastomers of PVC and PP thermoplastic materials. After the elastic body is cooled and shaped in the cooling box (6), the material reaches a certain hardness and strength, and is cut to a fixed length as required to obtain a glass fiber reinforced thermoplastic composite door and window profile.

[0008] After processing and assembling the glass fiber reinforced thermopl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com